Podcast

Questions and Answers

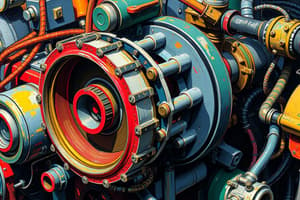

What happens to the paralleling valve when the engine reaches 16% RPM?

What happens to the paralleling valve when the engine reaches 16% RPM?

- It opens the path of fuel flow between the secondary and primary pump elements.

- It increases the RPM to 65%.

- It switches off the fuel pump.

- It closes the path of fuel flow between the secondary and primary pump elements. (correct)

Why does the fuel pump go into parallel mode during engine starting?

Why does the fuel pump go into parallel mode during engine starting?

- To maximize fuel pump volume. (correct)

- To restrict fuel flow.

- To reduce engine RPM.

- To minimize fuel pump volume.

What happens when the back pressure is felt due to the closed paralleling valve?

What happens when the back pressure is felt due to the closed paralleling valve?

- The centrifugal boost pump stops working.

- The primary pump check valve opens.

- The high pressure fuel filter opens up.

- The secondary pump check valve closes. (correct)

At what pressure does the secondary pump pressure switch close?

At what pressure does the secondary pump pressure switch close?

Why does a cockpit light illuminate when the secondary pump pressure switch closes?

Why does a cockpit light illuminate when the secondary pump pressure switch closes?

What is the purpose of the low pressure fuel filter in the fuel flow path?

What is the purpose of the low pressure fuel filter in the fuel flow path?

Why does each element have a separate fuel flow path in parallel mode?

Why does each element have a separate fuel flow path in parallel mode?

What initiates the closure of the paralleling valve?

What initiates the closure of the paralleling valve?

What happens when the engine speed governor reacts to speed variations?

What happens when the engine speed governor reacts to speed variations?

What is the role of the pilot servo valve rod in governing engine speed?

What is the role of the pilot servo valve rod in governing engine speed?

How does the spring cap react during acceleration when the power lever is moved upwards?

How does the spring cap react during acceleration when the power lever is moved upwards?

What function does the pilot servo valve serve in controlling air/fuel ratio changes?

What function does the pilot servo valve serve in controlling air/fuel ratio changes?

When the pilot valve rod moves downwards, what happens to the roller?

When the pilot valve rod moves downwards, what happens to the roller?

What is the purpose of compressing the flyweight speeder spring during acceleration?

What is the purpose of compressing the flyweight speeder spring during acceleration?

How does the roller cage position affect engine operation?

How does the roller cage position affect engine operation?

Which component helps prevent sudden air/fuel ratio changes in engine operation?

Which component helps prevent sudden air/fuel ratio changes in engine operation?

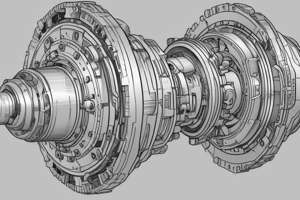

What differentiates the variable displacement pump from the constant displacement gear type pump?

What differentiates the variable displacement pump from the constant displacement gear type pump?

How is the pumping action produced in a variable displacement pump?

How is the pumping action produced in a variable displacement pump?

How is the action of a variable displacement pump infinitely varied?

How is the action of a variable displacement pump infinitely varied?

What causes variations in the movement of the servo piston in a variable displacement pump?

What causes variations in the movement of the servo piston in a variable displacement pump?

How does a fuel control unit regulate pump pressure and delivery in a variable displacement pump?

How does a fuel control unit regulate pump pressure and delivery in a variable displacement pump?

What is mechanically linked to the cam-plate in a variable displacement pump?

What is mechanically linked to the cam-plate in a variable displacement pump?

What is biased by springs to give full stroke position of the plungers in a variable displacement pump?

What is biased by springs to give full stroke position of the plungers in a variable displacement pump?

What effect does varying fuel servo pressure have on a servo piston in a variable displacement pump?

What effect does varying fuel servo pressure have on a servo piston in a variable displacement pump?

What happens to the burner pressure as the engine slows down?

What happens to the burner pressure as the engine slows down?

What does the multiplying linkage and roller mechanism do in response to the decrease in burner pressure?

What does the multiplying linkage and roller mechanism do in response to the decrease in burner pressure?

What happens when the new flyweight force reaches equilibrium with the speeder spring force?

What happens when the new flyweight force reaches equilibrium with the speeder spring force?

What is the purpose of allowing the engine to stabilize at idle before shutdown?

What is the purpose of allowing the engine to stabilize at idle before shutdown?

Why is it essential to follow a shutdown procedure on a simplified fuel control unit?

Why is it essential to follow a shutdown procedure on a simplified fuel control unit?

What is the role of the fuel shut-off valve during the shutdown process?

What is the role of the fuel shut-off valve during the shutdown process?

How do the flyweights position themselves after responding to a speed change?

How do the flyweights position themselves after responding to a speed change?

Why does burner pressure decrease as the engine slows down?

Why does burner pressure decrease as the engine slows down?

What does a supervisory electronic engine control system do?

What does a supervisory electronic engine control system do?

Which signals does the control amplifier in the system receive?

Which signals does the control amplifier in the system receive?

At what point does the electronic circuit in the control system start to function as a fuel limiting device?

At what point does the electronic circuit in the control system start to function as a fuel limiting device?

How does the pressure regulator in the installation regulate fuel flow?

How does the pressure regulator in the installation regulate fuel flow?

Which signals does the fuel flow regulator in the system receive?

Which signals does the fuel flow regulator in the system receive?

What role does the control amplifier play in the system?

What role does the control amplifier play in the system?

When does the pressure regulator reduce fuel flow to the spray nozzles?

When does the pressure regulator reduce fuel flow to the spray nozzles?

What triggers the electronic circuit to act as a fuel limiting device?

What triggers the electronic circuit to act as a fuel limiting device?

Flashcards are hidden until you start studying