Podcast

Questions and Answers

What is the primary reason timber is favored as a formwork material?

What is the primary reason timber is favored as a formwork material?

- It is more water-resistant than plywood.

- It can be cut to required sizes easily. (correct)

- It can be reused for multiple projects.

- It provides a higher thermal resistance than steel.

What is a disadvantage of using wet timber for formwork?

What is a disadvantage of using wet timber for formwork?

- It is not as lightweight as dry timber.

- It is too expensive compared to other materials.

- It is difficult to dismantle after use.

- It can absorb water from the concrete, reducing strength. (correct)

Which type of plywood is specifically recommended for use in formwork?

Which type of plywood is specifically recommended for use in formwork?

- Exterior plywood (correct)

- Veneer plywood

- Interior plywood

- Brittle plywood

What is one of the main advantages of using plywood in formwork?

What is one of the main advantages of using plywood in formwork?

Which characteristic of timber contributes to its ease of use on construction sites?

Which characteristic of timber contributes to its ease of use on construction sites?

Which formwork material is known to have limited reusability?

Which formwork material is known to have limited reusability?

How does high moisture content in timber affect the concrete during curing?

How does high moisture content in timber affect the concrete during curing?

What type of plywood layers are used to create exterior plywood?

What type of plywood layers are used to create exterior plywood?

Which of the following is NOT an advantage of plastic formwork?

Which of the following is NOT an advantage of plastic formwork?

What is a significant disadvantage of magnesium oxide boards?

What is a significant disadvantage of magnesium oxide boards?

Fabric formwork is known for which of the following advantages?

Fabric formwork is known for which of the following advantages?

Which type of scaffolding is specifically referred to as brick layer's scaffolding?

Which type of scaffolding is specifically referred to as brick layer's scaffolding?

What is a key characteristic of MgO boards when exposed to wet concrete?

What is a key characteristic of MgO boards when exposed to wet concrete?

Fabric formwork does NOT possess which of the following properties?

Fabric formwork does NOT possess which of the following properties?

What is the primary challenge faced when using MgO boards in humid conditions?

What is the primary challenge faced when using MgO boards in humid conditions?

Which of the following scaffolding types does not involve supporting structures directly attached to a wall?

Which of the following scaffolding types does not involve supporting structures directly attached to a wall?

What is one key advantage of using plywood in construction?

What is one key advantage of using plywood in construction?

What is a disadvantage of using steel as a formwork material?

What is a disadvantage of using steel as a formwork material?

Which of the following is a significant disadvantage of aluminum formwork?

Which of the following is a significant disadvantage of aluminum formwork?

What is a primary advantage of using plastics for formwork?

What is a primary advantage of using plastics for formwork?

How does plywood compare to timber in terms of reusability?

How does plywood compare to timber in terms of reusability?

Which factor does NOT contribute to the advantages of steel formwork?

Which factor does NOT contribute to the advantages of steel formwork?

In what scenario is plastic formwork particularly useful?

In what scenario is plastic formwork particularly useful?

What is a common limitation of aluminum formwork?

What is a common limitation of aluminum formwork?

What is the primary function of the cement paste in concrete?

What is the primary function of the cement paste in concrete?

Which characteristic is NOT considered in the ACI requirements for concrete?

Which characteristic is NOT considered in the ACI requirements for concrete?

What is the typical diameter range for coarse aggregate used in concrete?

What is the typical diameter range for coarse aggregate used in concrete?

Which of the following is a type of Portland cement designed to resist sulfate attack?

Which of the following is a type of Portland cement designed to resist sulfate attack?

What type of pozzolan cement is required for critical concrete works that need early strength?

What type of pozzolan cement is required for critical concrete works that need early strength?

In concrete classification, who is responsible for establishing the mixture proportion in a designed mixture?

In concrete classification, who is responsible for establishing the mixture proportion in a designed mixture?

Which material should coarse aggregates consist of to ensure durability and strength?

Which material should coarse aggregates consist of to ensure durability and strength?

What is one key factor that affects the workability of fresh concrete?

What is one key factor that affects the workability of fresh concrete?

What is the primary purpose of forms in reinforced concrete structures?

What is the primary purpose of forms in reinforced concrete structures?

Which of the following factors makes wood the most commonly used material for forms?

Which of the following factors makes wood the most commonly used material for forms?

How is the perimeter of a column form calculated?

How is the perimeter of a column form calculated?

What is the effective height used for calculating the area of a column form?

What is the effective height used for calculating the area of a column form?

How many sheets of plywood are needed for the forms if the total area calculated is 26.88m²?

How many sheets of plywood are needed for the forms if the total area calculated is 26.88m²?

Which type of lumber is suggested for forms that will only be used once or twice due to cost considerations?

Which type of lumber is suggested for forms that will only be used once or twice due to cost considerations?

What is the factor used to convert the number of plywood sheets needed into board feet of lumber?

What is the factor used to convert the number of plywood sheets needed into board feet of lumber?

What is a significant advantage of using plywood as forms over other materials?

What is a significant advantage of using plywood as forms over other materials?

Flashcards are hidden until you start studying

Study Notes

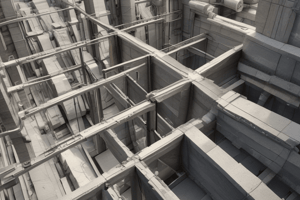

Formwork Materials

- Various materials are used for formwork including timber, plywood, steel, aluminum, plastics, magnesium, and fabric.

Timber as Formwork Material

- Timber is the most common formwork material, also known as traditional formwork.

- Advantages:

- Easily cut into required sizes.

- Lightweight and easy to handle.

- Good thermal resistance, protecting concrete in colder conditions.

- Simple construction method understood by workers.

- Easy to replace damaged parts and dismantle forms.

- Disadvantages:

- Dry timber can absorb moisture, reducing concrete strength.

- Wet timber may compress concrete, causing cracks and leaks.

- Limited reuse, making it less economical over time.

Plywood as Formwork Material

- Manufactured from veneer layers, plywood offers a smooth finish, reducing finishing costs.

- Advantages:

- Easily cut and available in large sizes, facilitating quicker construction.

- Strong, durable, and lightweight.

- Allows creation of curved forms and offers more reusability than timber.

- Disadvantages:

- Higher cost compared to timber.

- Thin sheets may bow under concrete weight without adequate thickness.

Steel as Formwork Material

- Steel formwork is durable and offers an excellent surface finish, ideal for mass structures like bridges and dams.

- Advantages:

- Strong, durable, and allows great reusability.

- Provides a uniform and smooth finish.

- Easy to assemble and dismantle.

- Disadvantages:

- High cost and heavy weight requiring lifting equipment.

- Susceptible to corrosion when in contact with water.

Aluminum as Formwork Material

- Gaining popularity for its lightweight and strength, used mainly in pre-fabricated formworks.

- Advantages:

- Easy to handle and repeatedly reusable.

- Enables simultaneous casting of walls and slabs, ensuring crack-free structures.

- Disadvantages:

- May deflect under maximum load; architectural modifications are limited.

Plastics as Formwork Material

- Suitable for small or complex structures, lightweight and durable.

- Advantages:

- Good water resistance and easily recyclable.

- Can create complex shapes without difficulty.

- Disadvantages:

- Weak against heat and generally more expensive.

- Limited load-bearing capacity.

Magnesium as Formwork Material

- Used in the form of magnesium oxide (MgO) boards, notable for multiple applications.

- Advantages:

- Lightweight, fireproof, waterproof, and environmentally friendly.

- Strong enough to resist heavy loads.

- Disadvantages:

- Corrosion risk when in contact with wet concrete.

- Requires skilled supervision for installation, sensitive to humid conditions.

Fabric as Formwork Material

- A modern construction technology that allows for complex shapes.

- Advantages:

- Extremely lightweight and economical.

- Waterproof and does not affect concrete properties; easy to remove post-hardening.

- Disadvantages:

- Requires skilled labor for precise installations.

Types of Scaffolding

- Types include single, double, cantilever, suspended, trestle, steel, and patented scaffolding.

Single Scaffolding

- Primarily used for brick masonry, consisting of standards, ledgers, and putlogs placed parallel to walls.

Forms in Reinforced Concrete Structures

- Forms, essential for shaping concrete structural members, must be simple to install, remove, and reuse.

- Common materials include wood, plywood, and phenolic boards due to their light weight and durability.

Lumber Types for Forms

- Good lumber: Durable, rough lumber used for formwork.

- Secondhand lumber: Cheaper, may have holes.

- Coco-lumber: Economical for limited use.

Steps to Calculate Forms for Columns

- Determine the perimeter of the column factoring in lapping.

- Calculate the total area of the forms needed.

- Compute the number of plywood sheets required based on the area.

Cement Types

- Portland Cement: Hydraulic cement with multiple types based on heat and strength properties.

- Pozzolan Cement: Mixture of Portland cement and pozzolanic materials aiming for specific construction needs.

Characteristics of Concrete

- Key characteristics include workability, strength, durability, and economy, influenced primarily by water to cement ratio.

Concrete Classification

- Designed mixture: Contractor establishes proportions for strength and workability.

- Prescribed mixture: Engineer specifies proportions while the contractor provides the correct mix.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.