Podcast

Questions and Answers

What is the primary benefit of using metal clamps or special wedge pin connections in formwork?

What is the primary benefit of using metal clamps or special wedge pin connections in formwork?

- They are costly to produce and maintain.

- They complicate the formwork process.

- They provide secure connections that are easy to assemble and dismantle. (correct)

- They require special tools for assembly.

What is the primary purpose of formwork in concrete construction?

What is the primary purpose of formwork in concrete construction?

- To mold the concrete into a desired size and shape (correct)

- To allow for immediate curing of the concrete

- To permanently shape the concrete once poured

- To support the structure during the entire construction period

Which material was previously the most common for formwork?

Which material was previously the most common for formwork?

- Concrete

- Lumber (correct)

- Plastic

- Metal

Why should the size of form sections be limited to the capacity of the largest crane planned?

Why should the size of form sections be limited to the capacity of the largest crane planned?

What is a disadvantage of high lifts in wall construction?

What is a disadvantage of high lifts in wall construction?

What is a limitation of timber formwork?

What is a limitation of timber formwork?

How has modern formwork technology enhanced construction practices?

How has modern formwork technology enhanced construction practices?

Which of the following describes the function of ties in formwork?

Which of the following describes the function of ties in formwork?

Under what condition can bending stresses for lumber be increased by 25%?

Under what condition can bending stresses for lumber be increased by 25%?

What are some objectives of building forms in concrete construction?

What are some objectives of building forms in concrete construction?

What challenge does formwork disassembly often face?

What challenge does formwork disassembly often face?

What is the role of the wales in a concrete formwork system?

What is the role of the wales in a concrete formwork system?

What design consideration is important for reinforcement during formwork installation?

What design consideration is important for reinforcement during formwork installation?

What type of formwork involves prefabricated modules?

What type of formwork involves prefabricated modules?

Which of the following is NOT considered an objective of formwork?

Which of the following is NOT considered an objective of formwork?

Which of the following statements about anchors in formwork is correct?

Which of the following statements about anchors in formwork is correct?

What is a key characteristic of Stay-In-Place Structural Systems?

What is a key characteristic of Stay-In-Place Structural Systems?

Which quality must formwork possess to ensure the desired shape of the concrete is maintained?

Which quality must formwork possess to ensure the desired shape of the concrete is maintained?

What happens to wood when the moisture content exceeds 19%?

What happens to wood when the moisture content exceeds 19%?

What is the effect of designing formwork for maximum reuse?

What is the effect of designing formwork for maximum reuse?

What is a significant factor that contractors must plan for when bidding on a project involving concrete formwork?

What is a significant factor that contractors must plan for when bidding on a project involving concrete formwork?

How does increasing the cross-sectional size of lumber affect allowable stresses?

How does increasing the cross-sectional size of lumber affect allowable stresses?

What is the purpose of the Horizontal Shear Constant (CH) in lumber?

What is the purpose of the Horizontal Shear Constant (CH) in lumber?

Which of the following is NOT a consideration when preparing formwork?

Which of the following is NOT a consideration when preparing formwork?

How can shop-built forms provide an advantage in formwork construction?

How can shop-built forms provide an advantage in formwork construction?

Which factor is NOT considered important regarding lateral pressure of concrete?

Which factor is NOT considered important regarding lateral pressure of concrete?

What role does form stability play in concrete construction?

What role does form stability play in concrete construction?

What is a key characteristic of plywood mentioned in formwork design?

What is a key characteristic of plywood mentioned in formwork design?

What is a potential drawback of using prefabricated forms?

What is a potential drawback of using prefabricated forms?

What is the significance of the Rolling Shear Constant in plywood?

What is the significance of the Rolling Shear Constant in plywood?

Under which condition does temperature adjustment occur for allowable stresses?

Under which condition does temperature adjustment occur for allowable stresses?

What should be used for calculating deflection in plywood without calculating moment of inertia?

What should be used for calculating deflection in plywood without calculating moment of inertia?

Flashcards are hidden until you start studying

Study Notes

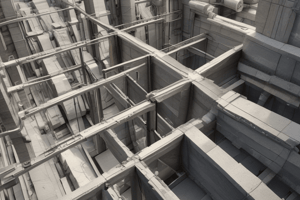

Formwork for Concrete

- Formwork is a temporary structure that molds and supports freshly poured concrete until it sets and becomes self-supporting.

- Development of formwork has evolved alongside concrete construction in the 20th century due to increased utilization of concrete as a primary construction material.

- Components of formwork, including connections, braces, and anchorages, are also temporary.

- Formwork materials must be durable and maintainable, as they are reused multiple times.

Types of Formwork

- Timber Formwork: Traditionally made on-site from lumber and plywood; labor-intensive with a shorter lifespan. It's flexible and more economical in regions with low labor costs.

- Prefabricated Modular Formwork: Constructed off-site and easily assembled; made from steel, aluminum, or high-density plastics. Offers durability and improved surface finish.

- Stay-In-Place Structural Systems: Utilize prefabricated materials and remain permanently in position post-concrete curing. Suitable for columns, piers, and bridge decks.

Formwork Design and Goals

- Proper design maximizes reuse while ensuring safety and quality.

- Critical objectives include maintaining strength, alignment, and dimensions during and after material placement.

- Forms must be rigid under loads, stable for alignment, and capable of enduring repeated handling.

Economic Considerations and Techniques

- Significant percentages of construction costs are attributed to formwork; planning during bidding is essential.

- Strategies to economize:

- Design forms for maximum reuse.

- Use shop-built forms for efficiency.

- Consider rental options for prefabricated forms.

- Utilize cranes effectively to handle large load sections.

- Optimize concrete placement by avoiding high lifts to reduce complications.

Form Materials and Properties

- Plywood is commonly used, known for its economical large panels and smooth surface finish.

- Key properties of lumber, such as allowable stresses, moisture effect, and size adjustments, must be considered in the design of formwork.

- Plywood's performance is enhanced with cross banding, offering strength in two dimensions.

Loads and Forces on Formwork

- Fresh concrete exerts hydrostatic pressure as it behaves like a fluid during placement.

- Factors influencing lateral pressure include concrete mixture density, temperature, placement rate, and use of admixtures.

- Understanding allowable stresses in wood is crucial for ensuring formwork integrity, including adjustments for load duration, moisture, and temperature.

Essential Components of Formwork

- Ties: Hold concrete forms together under fluid pressure; designed for partial or complete removal.

- Anchors and Clamps: Used to support and position formwork against lateral pressures.

- Ensure plywood and lumber are free from defects to maintain allowable stresses and prevent failure during the construction phase.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.