Podcast

Questions and Answers

What does NPSH stand for and why is it crucial for pumps?

What does NPSH stand for and why is it crucial for pumps?

- Net Power Siphon Head; it gauges the energy output of a pump.

- Net Positive Suction Head; it indicates the minimum pressure required at the pump inlet to prevent cavitation. (correct)

- Net Pump Speed Head; it is used to determine the flow rate of water.

- Net Positive Suction Head; it measures the efficiency of a pump.

Which factor is NOT a typical design consideration for fluid machines?

Which factor is NOT a typical design consideration for fluid machines?

- Design aesthetics and color selection (correct)

- Fluid properties including density and viscosity

- Operating conditions such as temperature and pressure

- Material selection for corrosion and wear resistance

What are frictional losses in fluid machines primarily caused by?

What are frictional losses in fluid machines primarily caused by?

- Fluid viscosity and surface friction (correct)

- An increase in fluid density

- High rotational speeds within the machine

- Ineffective material selection for components

Which of the following is a future trend in fluid machine development?

Which of the following is a future trend in fluid machine development?

Which application relies heavily on the use of pumps in industrial settings?

Which application relies heavily on the use of pumps in industrial settings?

What is the primary function of prime movers in fluid machines?

What is the primary function of prime movers in fluid machines?

Which component of a fluid machine is specifically used to increase fluid pressure?

Which component of a fluid machine is specifically used to increase fluid pressure?

What principle relates pressure, velocity, and elevation of a fluid in steady flow?

What principle relates pressure, velocity, and elevation of a fluid in steady flow?

Which type of pump utilizes rotating blades to increase the velocity of a fluid?

Which type of pump utilizes rotating blades to increase the velocity of a fluid?

What is the role of bearings in fluid machines?

What is the role of bearings in fluid machines?

What type of fluid machine is a gas turbine?

What type of fluid machine is a gas turbine?

Which equation states that the mass flow rate into a fluid machine equals the mass flow rate out of it?

Which equation states that the mass flow rate into a fluid machine equals the mass flow rate out of it?

In which type of pump does fluid move along the axis of rotation?

In which type of pump does fluid move along the axis of rotation?

Flashcards

Fluid Machine Efficiency

Fluid Machine Efficiency

Ratio of output power to input power; measures how much input energy is converted into useful output.

Pump NPSH

Pump NPSH

Minimum pressure needed at pump inlet to prevent cavitation (bubbles forming and collapsing).

Turbine Application

Turbine Application

Used in power generation, typically hydroelectric and steam power plants.

Fluid Machine Losses

Fluid Machine Losses

Signup and view all the flashcards

Pump Use in HVAC

Pump Use in HVAC

Signup and view all the flashcards

Fluid Machines

Fluid Machines

Signup and view all the flashcards

Prime Movers

Prime Movers

Signup and view all the flashcards

Fluid Motors

Fluid Motors

Signup and view all the flashcards

Impeller

Impeller

Signup and view all the flashcards

Diffuser

Diffuser

Signup and view all the flashcards

Conservation of Mass (Fluid machines)

Conservation of Mass (Fluid machines)

Signup and view all the flashcards

Conservation of Energy (Fluid Machines)

Conservation of Energy (Fluid Machines)

Signup and view all the flashcards

Bernoulli's Principle (Fluid Machines)

Bernoulli's Principle (Fluid Machines)

Signup and view all the flashcards

Study Notes

Introduction

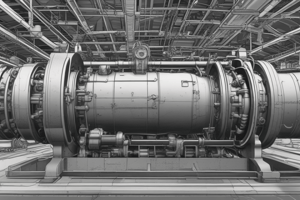

- Fluid machines are devices that convert energy from one form to another, utilizing fluid flow.

- This conversion can involve converting mechanical energy into fluid energy, or vice-versa.

- Common examples include pumps, turbines, compressors, and fans.

- They are crucial in various applications, including power generation, industrial processes, and transportation.

Classification of Fluid Machines

- Fluid machines are broadly categorized into:

- prime movers: These machines convert mechanical energy into fluid energy (e.g., pumps).

- fluid motors: These machines extract energy from the flow of a fluid to produce mechanical power (e.g., turbines).

Key Components of Fluid Machines

- Impeller: A rotating component used to impart velocity and pressure to the fluid.

- Diffuser: A component that converts the kinetic energy of the fluid into pressure energy, typically following the impeller.

- Nozzle: A component that accelerates the fluid to a high velocity.

- Casings: These enclose the rotating components and guide the fluid flow.

- Bearings: Support the rotating parts and reduce friction.

Principles of Operation

- Conservation of mass: The mass flow rate into a fluid machine equals the mass flow rate out of it.

- Conservation of energy: The energy input to the machine equals the energy output plus any losses.

- Bernoulli's principle: Provides a relationship between pressure, velocity, and elevation of a fluid in steady flow.

- Momentum equation: Relates the forces acting on a fluid to the changes in its momentum.

- Energy equation: A fundamental equation relating the various forms of energy in a fluid system.

Types of Fluid Machines

-

Pumps: Devices that increase the pressure of a fluid by converting mechanical energy into fluid pressure energy. Types include:

-

Centrifugal pumps: Employ rotating impellers to increase fluid velocity and pressure.

-

Axial pumps: Move fluid along the axis of rotation.

-

Reciprocating pumps: Use pistons or plungers in a back-and-forth motion to move the fluid.

-

Turbines: Devices that extract energy from the flow of a fluid, converting fluid energy into mechanical energy. Types include:

-

Hydraulic turbines: Utilize water or other liquids as the working fluid.

-

Steam turbines: Utilize steam as the working fluid.

-

Gas turbines: Utilize gas as the working fluid.

Performance Characteristics

- Head: The pressure difference across the machine.

- Flow rate: The volume of fluid handled per unit time.

- Efficiency: The ratio of output power to input power.

- Power output: The rate at which work is done by the machine.

- Specific speed: A dimensionless number that indicates the type of machine and its operating range.

- NPSH (Net Positive Suction Head): A crucial parameter for pumps, indicating the minimum pressure required at the pump inlet to prevent cavitation.

Applications

- Power generation: Turbines are used in hydroelectric and steam power plants.

- Industrial processes: Pumps are essential for moving fluids in various industrial settings.

- Transportation: Fluid machines are utilized for tasks like engine cooling, hydraulic systems for braking, and fuel delivery.

- HVAC systems: Pumps are used for circulating cooling and heating fluids.

Design Considerations

- Fluid properties (density, viscosity)

- Operating conditions (pressure, temperature, flow rate)

- Required performance (head, flow rate, efficiency)

- Material selection considering corrosion and wear resistance

- Economic factors

Losses in Fluid Machines

- Frictional losses: Occur due to fluid viscosity and surface friction.

- Hydraulic losses: Occur due to the flow conditions within the machine.

- Mechanical losses: Occur due to friction in the bearings and seals.

- Irreversibilities in the flow: Efficiencies are ultimately impacted by factors that lead to the conversion of energy to heat, which cannot be fully recovered.

Future Trends

- Increased focus on energy efficiency

- Development of advanced materials and designs

- Integration of fluid machines with other systems

- Optimization for specific applications

- Development of machines for unconventional fluid systems (e.g., cryogenic fluids)

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.