Podcast

Questions and Answers

What is the primary purpose of pressurising the oil reservoir in a dry-sump oil system?

What is the primary purpose of pressurising the oil reservoir in a dry-sump oil system?

- To allow for easier oil drainage

- To prevent oil foaming and pump cavitation (correct)

- To facilitate oil storage during servicing

- To increase the viscosity of the oil

What minimum expansion space is required in an oil reservoir?

What minimum expansion space is required in an oil reservoir?

- 5% of tank capacity

- 1 gal or 10% of tank capacity, whichever is lesser

- 10% of tank capacity or 0.5 gal, whichever is greater (correct)

- 15% of tank capacity

What is the primary function of the engine lubrication system?

What is the primary function of the engine lubrication system?

- To filter oil before it enters the engine

- To regulate air pressure in the engine compartments

- To supply oil to reduce friction and cool engine components (correct)

- To store fuel for engine operation

What function do scavenge pumps serve in a dry-sump oil system?

What function do scavenge pumps serve in a dry-sump oil system?

How does the lubrication system help deal with heat radiating into the engine?

How does the lubrication system help deal with heat radiating into the engine?

What is a notable characteristic of oil consumption in gas turbine engines compared to piston engines?

What is a notable characteristic of oil consumption in gas turbine engines compared to piston engines?

Where is the adjustable relief valve typically installed in a dry-sump oil system?

Where is the adjustable relief valve typically installed in a dry-sump oil system?

What is the purpose of marking oil filler caps with the word 'OIL'?

What is the purpose of marking oil filler caps with the word 'OIL'?

What is the function of the pressure relief valve system in an engine lubrication system?

What is the function of the pressure relief valve system in an engine lubrication system?

What type of lubrication system is preferred when bearing vent cavities are under high air pressure?

What type of lubrication system is preferred when bearing vent cavities are under high air pressure?

How does the expansion space in the oil reservoir affect oil management?

How does the expansion space in the oil reservoir affect oil management?

What is the purpose of the oil reservoir in an engine lubrication system?

What is the purpose of the oil reservoir in an engine lubrication system?

What risk is mitigated by the combination of pressure regulation and expansion space in the oil reservoir?

What risk is mitigated by the combination of pressure regulation and expansion space in the oil reservoir?

What is a scupper drain used for in an oil reservoir?

What is a scupper drain used for in an oil reservoir?

How is oil returned to the storage tank in a lubrication system?

How is oil returned to the storage tank in a lubrication system?

Why is careful temperature control essential in engine lubrication systems?

Why is careful temperature control essential in engine lubrication systems?

What is the primary function of a bypass valve in an oil system?

What is the primary function of a bypass valve in an oil system?

Which type of filter is NOT mentioned as a common type found in oil systems?

Which type of filter is NOT mentioned as a common type found in oil systems?

What happens when a blockage occurs in the oil system?

What happens when a blockage occurs in the oil system?

What signals may indicate that a component is blocked in the oil system?

What signals may indicate that a component is blocked in the oil system?

What is a characteristic of laminated paper filters used in oil systems?

What is a characteristic of laminated paper filters used in oil systems?

What type of valves are usually incorporated within an oil cooler?

What type of valves are usually incorporated within an oil cooler?

Why are oil filters essential in lubrication systems?

Why are oil filters essential in lubrication systems?

In the event of a blockage in an oil filter, how does the system respond?

In the event of a blockage in an oil filter, how does the system respond?

What is the primary function of thread filters in gas turbine engines?

What is the primary function of thread filters in gas turbine engines?

Which statement accurately describes the construction of a thread filter?

Which statement accurately describes the construction of a thread filter?

What role does the bypass valve in oil filters play?

What role does the bypass valve in oil filters play?

Why is it important for turbine-powered aircraft to have a warning light for the oil filter?

Why is it important for turbine-powered aircraft to have a warning light for the oil filter?

What can be inferred about the filtration capability of a thread filter with finer-pitched threads?

What can be inferred about the filtration capability of a thread filter with finer-pitched threads?

What happens when an oil filter becomes completely blocked?

What happens when an oil filter becomes completely blocked?

What type of indicator is often added to filter housing as a visual bypass warning?

What type of indicator is often added to filter housing as a visual bypass warning?

In terms of oil filtration, what is the consequence of using unfiltered oil for lubricating main bearings?

In terms of oil filtration, what is the consequence of using unfiltered oil for lubricating main bearings?

What is the primary purpose of vents or breathers in oil tanks and bearing chambers?

What is the primary purpose of vents or breathers in oil tanks and bearing chambers?

What role does air pressure play in oil tanks and bearing chambers?

What role does air pressure play in oil tanks and bearing chambers?

Which type of breather is most commonly used in oil vent systems?

Which type of breather is most commonly used in oil vent systems?

What is the function of a centrifugal breather in the oil vent system?

What is the function of a centrifugal breather in the oil vent system?

What is the typical pressure maintained by the vent pressurising valve within oil tanks and bearing chambers?

What is the typical pressure maintained by the vent pressurising valve within oil tanks and bearing chambers?

What components are involved in the vent-pressurising valve?

What components are involved in the vent-pressurising valve?

What happens to the clean vent air in a typical oil vent system?

What happens to the clean vent air in a typical oil vent system?

Why is a certain amount of air pressure necessary in the bearing chambers?

Why is a certain amount of air pressure necessary in the bearing chambers?

Flashcards are hidden until you start studying

Study Notes

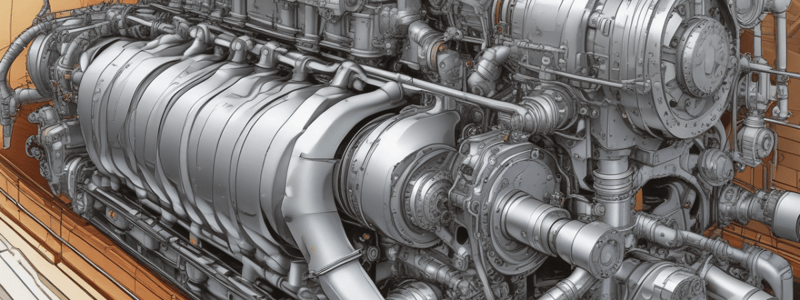

Engine Lubrication Systems

- Lubrication system's primary role is supplying oil to engine parts to combat friction and heat.

- Engine heat is managed through the nacelle ventilation system and internal lubrication.

- Oil is pressurized and circulated to reduce friction, cool components, and maintain cleanliness.

- Capitalizes on a scavenging system that returns oil to storage for reuse.

- Gas turbine engines have lower oil consumption compared to piston engines, resulting in smaller bulk oil storage requirements (3-5 L for business jets, 20-30 L for commercial engines).

- Oil remains relatively clean due to minimal exposure to combustion products and efficient filtration.

- Oil temperature is monitored and controlled through automatic cooling devices to prevent rapid decomposition.

Lubrication System Types

- Two self-contained lubrication systems utilized in gas turbine engines: Pressure relief valve system and Full flow system.

- Pressure relief valve system limits oil pump pressure; full flow system allows pressure variance with RPM.

Lubrication System Classifications

- Lubrication systems categorized as Wet-sump or Dry-sump.

- Wet-sump: Oil stored directly in the engine.

- Dry-sump: Oil stored in an external reservoir; scavenge pumps collect accumulated oil for recirculation.

Oil Reservoir

- Essential for holding sufficient oil for maximum operation duration.

- Reservoirs are often pressurized to ensure positive oil flow and suppress foaming, preventing pump cavitation.

- Pressurization is achieved using an adjustable relief valve in the vent line.

Expansion Space

- Oil reservoirs feature a minimum 10% expansion space or 0.5 gallons for oil expansion and foam collection.

- Oil filler caps marked with "OIL" and permissible oil designations for proper identification.

- Many dry-sump system reservoirs include scupper drains to catch spills and overflows during servicing.

Bypass Valves

- Bypass valves are critical for preventing oil starvation if a component becomes blocked.

- Operates similarly to pressure relief valves, allowing oil to bypass when pressure increases due to blockage.

- Incorporated in all filters and oil coolers with indicators to signal when a blockage occurs.

Oil Filters

- Oil filters are crucial for removing contaminants from lubrication systems.

- Common types include Laminated paper, Cleanable screen, Screen and spacer, and Thread filters.

Thread Filters

- Act as ‘last chance’ filters, positioned before the oil jets that lubricate bearings.

- Designed with a threaded inner element for effective oil filtration prior to entering bearings.

Oil Filter Bypass

- All oil filters must allow full oil flow even if blocked, achieved through an integrated oil bypass valve.

- Warning systems, including cockpit lights and visual indicators, alert operators to bypass situations.

Vents

- Vents, or breathers, are integral for preventing excess air pressure within oil tanks and bearing chambers.

- Essential for ensuring proper oil gravity feeding and effective scavenging.

- Commonly employs a centrifugal breather design, using centrifugal force to separate oil from air and return it to the sump while venting clean air.

- Most systems maintain a 5–7 psi pressure head using a vent-pressurizing valve with a spring-loaded pressure relief valve.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.