Podcast

Questions and Answers

What type of warning light is commonly used in oil pressure systems of turbine engines?

What type of warning light is commonly used in oil pressure systems of turbine engines?

- Temperature warning light

- High-pressure warning light

- Low-oil pressure warning light (correct)

- Pressure gauge alert light

Where is the turbine engine pressure gauge typically connected in the oil system?

Where is the turbine engine pressure gauge typically connected in the oil system?

- At the engine bearings

- At the oil temperature sensor

- Before the oil cooler

- Downstream of the main oil filter (correct)

When does the low oil pressure warning light extinguish during the engine start sequence?

When does the low oil pressure warning light extinguish during the engine start sequence?

- When electrical power is turned on

- When the oil temperature rises

- When oil pressure exceeds the low limit (correct)

- When the engine stops running

Which component is positioned between the oil temperature sensor and the engine bearings?

Which component is positioned between the oil temperature sensor and the engine bearings?

What electronic display system do modern aircraft use for engine oil indication?

What electronic display system do modern aircraft use for engine oil indication?

Which of the following is measured by the oil filter differential pressure switch?

Which of the following is measured by the oil filter differential pressure switch?

What happens to the low oil pressure light when the engine is not running and electrical power is on?

What happens to the low oil pressure light when the engine is not running and electrical power is on?

Where is the oil temperature sensor located in relation to the oil system components?

Where is the oil temperature sensor located in relation to the oil system components?

What is the primary purpose of continuously supplying cooling air into the turbine disc cavities?

What is the primary purpose of continuously supplying cooling air into the turbine disc cavities?

How is the flow and pressure of the cooling air in the turbine disc cavities managed?

How is the flow and pressure of the cooling air in the turbine disc cavities managed?

Where does the cooling air go after flowing over the turbine disc faces?

Where does the cooling air go after flowing over the turbine disc faces?

What is a significant role of the external cooling system in the engine bay or pod?

What is a significant role of the external cooling system in the engine bay or pod?

Why is it important to minimize the airflow around the engine?

Why is it important to minimize the airflow around the engine?

What is a primary characteristic of simplex fuel nozzles?

What is a primary characteristic of simplex fuel nozzles?

What is the role of the internal check valve in a simplex fuel nozzle?

What is the role of the internal check valve in a simplex fuel nozzle?

What happens if hot mainstream gas is ingested into the turbine disc cavities?

What happens if hot mainstream gas is ingested into the turbine disc cavities?

At which engine operational conditions are simplex nozzles most effective?

At which engine operational conditions are simplex nozzles most effective?

What controls the airflow over the turbine disc faces?

What controls the airflow over the turbine disc faces?

What is the effect of excess hot gas ingestion on turbine discs?

What is the effect of excess hot gas ingestion on turbine discs?

What defines duplex fuel nozzles compared to simplex fuel nozzles?

What defines duplex fuel nozzles compared to simplex fuel nozzles?

What is the function of the primary flow in duplex fuel nozzles?

What is the function of the primary flow in duplex fuel nozzles?

Why are simplex nozzles considered unsatisfactory at low pressures?

Why are simplex nozzles considered unsatisfactory at low pressures?

Which configuration is utilized by duplex fuel nozzles?

Which configuration is utilized by duplex fuel nozzles?

How does the simplex design impart swirling motion to the fuel?

How does the simplex design impart swirling motion to the fuel?

What happens to the main metering valve when Px air contracts the acceleration bellows?

What happens to the main metering valve when Px air contracts the acceleration bellows?

Which force is greater causing the flyweights to move outwards when the power lever is retarded?

Which force is greater causing the flyweights to move outwards when the power lever is retarded?

What effect does the opening of the governor valve have on Py air?

What effect does the opening of the governor valve have on Py air?

What role does the bypass valve play in the fuel pump system?

What role does the bypass valve play in the fuel pump system?

What primarily controls the metering valve position in this system?

What primarily controls the metering valve position in this system?

When the governor rod moves up due to Px air expansion, what is the subsequent action of the main metering valve?

When the governor rod moves up due to Px air expansion, what is the subsequent action of the main metering valve?

Which of the following parameters is considered secondary in controlling the metering valve?

Which of the following parameters is considered secondary in controlling the metering valve?

What happens to the deceleration bellows as engine speed slows?

What happens to the deceleration bellows as engine speed slows?

What type of seal is used between the mating faces of components in the flexible elbow system?

What type of seal is used between the mating faces of components in the flexible elbow system?

What is the purpose of the V-band type clamp in the flexible elbow assembly?

What is the purpose of the V-band type clamp in the flexible elbow assembly?

What do temperature compensators allow ducts to do in response to thermal expansion?

What do temperature compensators allow ducts to do in response to thermal expansion?

Where are one-way check valves typically located within the system?

Where are one-way check valves typically located within the system?

What issue do temperature compensators specifically address in larger aircraft?

What issue do temperature compensators specifically address in larger aircraft?

Which of the following best describes the insulation provided in the flexible elbow system?

Which of the following best describes the insulation provided in the flexible elbow system?

What function does the check valve serve in relation to the APU?

What function does the check valve serve in relation to the APU?

Which component is NOT mentioned as a source for airflow controlled by check valves?

Which component is NOT mentioned as a source for airflow controlled by check valves?

Flashcards are hidden until you start studying

Study Notes

Oil System Indication

- Oil system incorporates gauges for pressure, quantity, low pressure, filter differential, and temperature.

- Oil pressure gauge is located downstream of the main oil filter for accurate engine pressure indication.

- Low oil pressure warning light illuminates when electrical power is on, turning off once oil pressure exceeds the low limit.

- Oil temperature sensor is placed in the pressure line before reaching engine bearings and after filters and coolers.

ECAM/EICAS Engine Oil Indication

- Modern aircraft display engine oil indication electronically via ECAM or EICAS in the cockpit.

- Governor mechanisms utilize air pressure to maintain stable fuel flow and engine RPM.

- Changes in engine RPM modify governor and metering valve positions, impacting fuel flow.

- Simplex fuel nozzles provide a single spray pattern with an internal check valve to prevent fuel dribble after shutdown.

- Duplex fuel nozzles feature primary and secondary flows, with distinct orifice sizes for varying engine operations.

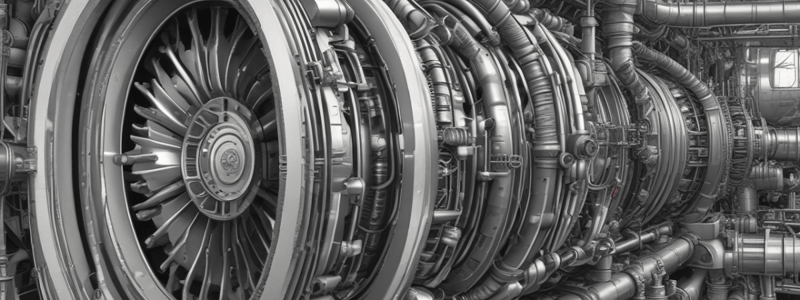

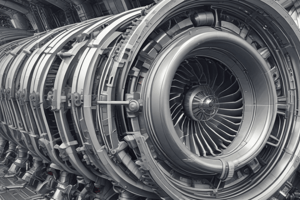

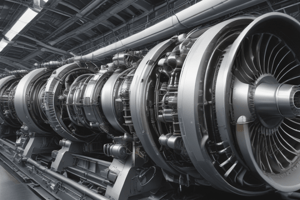

Pre-Swirl Nozzle Cooling System

- Hot gas ingestion can cause turbine disc overheating and fatigue.

- Cooling air is supplied to turbine disc cavities to prevent hot gas entry, with flow controlled by interstage seals.

Turbine Disc Cooling

- Cooling air flows through annular spaces between turbine discs and is expelled into the main gas stream after heat absorption.

- Airflow management across disc faces is regulated by interstage seals to optimize cooling efficiency.

External Cooling

- Engine bay cooled by external atmospheric air, purging flammable vapors while minimizing drag.

- Ventilation systems are designed to efficiently manage temperature around the engine components.

Crush Type Seal and Insulation

- Crush seals are used between mating component faces, secured with V-band clamps for tight connections.

- Insulation blankets cover joints to prevent heat loss and enhance thermal efficiency.

Temperature Compensators

- Temperature compensators are employed to allow duct expansion due to temperature variations.

- Slip joints in compensators accommodate duct growth without structural issues.

Check Valves

- One-way check valves regulate airflow from sources like APU and external connections.

- Check valves prevent loss of manifold pressure when the respective systems are inactive.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.