Podcast

Questions and Answers

What is the primary function of a Reheating Furnace in a rolling mill?

What is the primary function of a Reheating Furnace in a rolling mill?

- To cool the steel billet after rolling

- To increase the mechanical properties of deformed bars

- To heat the steel billet to the required temperature for rolling process (correct)

- To cut the head and tail of the bar for smooth entry to intermediate mill

What is the purpose of a Descale in a rolling mill?

What is the purpose of a Descale in a rolling mill?

Remove accumulated scales from the billet

Reversing mill in a rolling mill reverses the direction of rolled material after each pass.

Reversing mill in a rolling mill reverses the direction of rolled material after each pass.

True (A)

What product is primarily produced at Rolling Mill 3 in Emirates Steel?

What product is primarily produced at Rolling Mill 3 in Emirates Steel?

What is the annual production capacity of Rolling Mill 3?

What is the annual production capacity of Rolling Mill 3?

Which products are finished in Rolling Mill 4?

Which products are finished in Rolling Mill 4?

Rebar Mill 5 produces only rebar.

Rebar Mill 5 produces only rebar.

What is the weight of the finished products in Rolling Mill 5?

What is the weight of the finished products in Rolling Mill 5?

What is the role of a roughing mill?

What is the role of a roughing mill?

_____ & Cobble is used for head and tail cut of the bar, and emergency chopping purposes.

_____ & Cobble is used for head and tail cut of the bar, and emergency chopping purposes.

What is the function of a finishing block in the rolling mill?

What is the function of a finishing block in the rolling mill?

Match the following equipment with their functions:

Match the following equipment with their functions:

Ultra flexible reversing mills are composed of 3 reversing stands.

Ultra flexible reversing mills are composed of 3 reversing stands.

Flashcards are hidden until you start studying

Study Notes

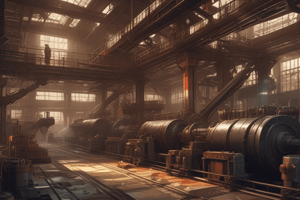

General Overview of ES Rolling Mills

- Understand the details of Rolling Mills in Emirates Steel and its process, as well as its application.

- Rolling is the process of shaping steel, where material is passed between rolls, reducing its cross-sectional area.

Basics of HOT Rolling Principle

- Rolling is a process that grips and deforms the material by the rolls, with its cross-sectional area being reduced.

- The rolls rotate at the same speed but in opposite directions (clockwise and counterclockwise).

Types of Rolling Mills @ Emirates Steel

- Emirates Steel has 5 rolling mills: RM1, RM2, RM3, RM4, and RM5.

- Rolling Mill 1, 2, and 5 are rebar mills; Rolling Mill 3 is a wire rod mill, and Rolling Mill 4 is a heavy section mill.

Introduction to RM1, RM2, RM3, RM4, and RM5 Plants

- Rolling Mill 1 is the first rolling mill plant in Emirates Steel, with a design capacity of 500,000 tons per year.

- Rolling Mill 2 is a rebar mill, commissioned in 2007, producing quality deformed bars with a maximum speed of 35 meters per second.

- Rolling Mill 3 is a wire rod mill, producing plain wire rod and deformed bars in coils, with a maximum speed of 100 meters per second.

- Rolling Mill 4 is a heavy section mill, producing beams, channels, angles, and sheet piles.

Rolling Mill Equipment

- Reheating Furnace: heats the steel billet to the required temperature for rolling.

- Descale: removes accumulated scales from the billet.

- Roughing Mill: reduces the cross-sectional area of the stock.

- Crop & Cobble Shear: cuts the head and tail of the bar for smooth entry to the intermediate mill.

- Vertical Stand: consists of two high cartridge stands with both rolls mounted vertically.

- Horizontal Stand: consists of two high cartridge stands with both rolls mounted horizontally.

- Fast Finishing Block: a compact rolling block with cantilever tungsten carbide rings.

- Cooling Bed: cools the bars after rolling.

- Cold Shear: cuts the rolled products into desired customer lengths.

- Quenching Unit: increases the mechanical properties of deformed bars.

- Bars Screw Counter Station: processes bar layers and counts the bars as per the preset numbers.

- Pinch Roll: drags the bar at the right speed.

- Wire Binding Machine: binds the bundle of rebars with wire.

- Dividing Shear: cuts the bars into multiple lengths according to the desired length.

- Removal Area: consists of storage roller tables, disappearing stop, and lifting chain transfer.

- Forming Station: produces final coils with better coil shape compactness and homogeneity.

- C Hook Conveyor: lifts and carries the coils from the forming station to the compactor.

- Coil Compactor: a horizontal compactor with four binding units for automatic compacting and binding.

- Unloading Station: the final station where the coils are picked up by forklift and transferred to the storage area.

ES Products

-

Rebars: used in civil engineering and building projects, produced as deformed bars in straight lengths or coils.

-

Wire Rods: used in various applications, including springs, electrodes, fencing wires, fasteners, cycle spokes, nails, and GI wires.

-

Heavy Sections: used in construction, industrial, and engineering applications, including beams, channels, angles, and sheet piles.### Profile Gauge for Dimension Measurement

-

Breakdown Mill: divides products in the cooling bed

-

Cooling bed: cools products from 850°C to 80°C

-

Straightening machine: uses spray marking on products

-

Layer preparation and quality inspection: prepares products for further processing

Rolling Mill 5 (Rebar Mill)

- Designed to produce rebar and plain bars

- Equipped with 18 stands in horizontal and vertical configuration

- Produces rebars and plain bars from billets

Glossary

- Rolling: shaping and reducing steel through rotating rolls

- Rolling Mill: a factory or machine for rolling steel into different products

- Billet: a type of raw material

- Wire rod: a finished product rolled from a billet in a wire rod mill, formed into coils

- Reheating furnace: heats raw material to required rolling temperature

- Descaler: equipment with pressurized water to remove scales from hot steel

- Roughing mill: reduces the cross-section of the stock

- Intermediate mill: further reduces rolled stock

- Finishing mill: where final shaping stage of hot rolling takes place

- Finishing block: stands with cantilever carbide rings placed 90° to each other

- Tempcore/Quenching: rapid cooling of bars to improve mechanical properties

Rolling Mill 5 Facts and Figures

- Annual production capacity: 500,000 tons

- Raw material: Billet 150mm x 150mm x 12m and 130mm x 130mm x 12m

- Pusher type furnace: 80 Ton per hour capacity

- Continuous rolling mill: with 18 stands in H and V configuration

- In-line Quenching process: rapid cooling of bars

- Cooling bed: cools bars cut to length from mill

- Dividing shear: cuts bars to length

- Cold shear: flying cold shear type for cutting different lengths

- Tying machines: bind final product bundles

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.