Podcast

Questions and Answers

The requirement for indigenization of systems approved under cross acceptance may be exempted by the Railway Board.

The requirement for indigenization of systems approved under cross acceptance may be exempted by the Railway Board.

True (A)

The manufacturer is obligated to ensure the availability of spare parts for a minimum of 20 years.

The manufacturer is obligated to ensure the availability of spare parts for a minimum of 20 years.

False (B)

The manufacturer must provide training on EI technology to Railway officials at their own facilities.

The manufacturer must provide training on EI technology to Railway officials at their own facilities.

True (A)

The manufacturer is required to establish a testing and repair facility with specialized equipment, including fault diagnostic systems and test jigs.

The manufacturer is required to establish a testing and repair facility with specialized equipment, including fault diagnostic systems and test jigs.

The annual repair contract is mandatory for a period of 10 years after the warranty expires.

The annual repair contract is mandatory for a period of 10 years after the warranty expires.

Type, acceptance, and routine tests are not required for systems approved under cross acceptance.

Type, acceptance, and routine tests are not required for systems approved under cross acceptance.

The manufacturer needs to provide certificates of type tests conducted according to national standards.

The manufacturer needs to provide certificates of type tests conducted according to national standards.

The manufacturer must submit a total of 5 documents to demonstrate compliance with the requirements in paragraph 15.

The manufacturer must submit a total of 5 documents to demonstrate compliance with the requirements in paragraph 15.

The manufacturer must provide a trouble-shooting chart that allows for the replacement of defective PCB cards at the site.

The manufacturer must provide a trouble-shooting chart that allows for the replacement of defective PCB cards at the site.

A detailed power supply arrangement is not required from the manufacturer.

A detailed power supply arrangement is not required from the manufacturer.

The manufacturer is responsible for providing the version number of signaling equipment according to their own practice during cross-acceptance.

The manufacturer is responsible for providing the version number of signaling equipment according to their own practice during cross-acceptance.

Software checksum of EPROMs must be provided as per RDSO/SPN/144.

Software checksum of EPROMs must be provided as per RDSO/SPN/144.

The documentation provided by the manufacturer does not include any details about the software algorithm or its validation procedure.

The documentation provided by the manufacturer does not include any details about the software algorithm or its validation procedure.

Visual inspection is included as part of the type tests.

Visual inspection is included as part of the type tests.

Environmental tests are not required for acceptance tests.

Environmental tests are not required for acceptance tests.

Only one equipment must pass all the type tests.

Only one equipment must pass all the type tests.

Computerised testing for permutations and combinations is part of the acceptance tests.

Computerised testing for permutations and combinations is part of the acceptance tests.

The purchaser or his nominee has the discretion to call for another equipment in case of failure.

The purchaser or his nominee has the discretion to call for another equipment in case of failure.

System Diagnostics test is not required for type tests.

System Diagnostics test is not required for type tests.

Acceptance tests have more requirements than type tests.

Acceptance tests have more requirements than type tests.

Fail-safety tests are conducted on all cards.

Fail-safety tests are conducted on all cards.

A flashing indication on the VDU screen signals that there is a healthy communication status between the VDU & EI.

A flashing indication on the VDU screen signals that there is a healthy communication status between the VDU & EI.

The colour monitor is considered healthy if only two of the three dot markers (Red, Blue, and Green) are displayed.

The colour monitor is considered healthy if only two of the three dot markers (Red, Blue, and Green) are displayed.

Diagnostic functions can be performed from the VDU terminal.

Diagnostic functions can be performed from the VDU terminal.

Hot standby VDU switch over can occur in case of a mouse failure.

Hot standby VDU switch over can occur in case of a mouse failure.

All power supply for VDU must be arranged by the Railways.

All power supply for VDU must be arranged by the Railways.

It is possible to display an enlarged view of a portion of the yard on the monitor.

It is possible to display an enlarged view of a portion of the yard on the monitor.

Operation of signal gear through multiple VDUs can occur simultaneously.

Operation of signal gear through multiple VDUs can occur simultaneously.

The current status of field equipment is displayed using a single color on the VDU screen.

The current status of field equipment is displayed using a single color on the VDU screen.

The EI system must comply with SIL-4 as defined by the CENELEC Standards.

The EI system must comply with SIL-4 as defined by the CENELEC Standards.

Any software used in EI does not need to conform to recognized standards for safety critical applications.

Any software used in EI does not need to conform to recognized standards for safety critical applications.

Independent validation of the EI system is unnecessary if it follows equivalent international standards.

Independent validation of the EI system is unnecessary if it follows equivalent international standards.

A certificate from an Independent Safety Assessor is essential to validate compliance with SIL-4.

A certificate from an Independent Safety Assessor is essential to validate compliance with SIL-4.

The firm must document all modifications made to the EI system after initial validation.

The firm must document all modifications made to the EI system after initial validation.

User Railway is responsible for the independent verification of EI system's standby changeover software.

User Railway is responsible for the independent verification of EI system's standby changeover software.

The application software related to yard data does not need to be verified by the User Railway.

The application software related to yard data does not need to be verified by the User Railway.

The EI system can be validated based on standards that are not recognized by safety standards bodies.

The EI system can be validated based on standards that are not recognized by safety standards bodies.

The Point and Signal modules must interface with Signals and point machines per IRS/S/24 without amendments.

The Point and Signal modules must interface with Signals and point machines per IRS/S/24 without amendments.

Outdoor gears interface requirements are provided by the purchaser.

Outdoor gears interface requirements are provided by the purchaser.

Relay driver modules are used to drive other field gears through a direct interface.

Relay driver modules are used to drive other field gears through a direct interface.

Surge protection is optional if the field gear is directly driven from the OC.

Surge protection is optional if the field gear is directly driven from the OC.

The medium of communication between CIU and OCs is RDSO approved Mono-mode OFC.

The medium of communication between CIU and OCs is RDSO approved Mono-mode OFC.

All outputs shall be brought to a safe state in case of communication failure between CIU and OC.

All outputs shall be brought to a safe state in case of communication failure between CIU and OC.

Communication devices connecting Central EI with Object controllers need not meet any specific safety standards.

Communication devices connecting Central EI with Object controllers need not meet any specific safety standards.

A network monitoring system is instituted to check the perfection of the OFC network connection.

A network monitoring system is instituted to check the perfection of the OFC network connection.

Flashcards

Standards for Electronic Interlockings

Standards for Electronic Interlockings

The electronic interlockings shall be capable of controlling Points and Signals in accordance with RDSO/SPN/153 and IRS/S/24 standards.

Interface Requirements for Outdoor Gears

Interface Requirements for Outdoor Gears

The interface requirements for outdoor gears shall be provided by the purchaser. This information is crucial for ensuring proper integration and functionality.

Field Gear Operation

Field Gear Operation

Field gears (devices outside the main control center) are operated through relays using Relay drivers.

Object Controller Location

Object Controller Location

Signup and view all the flashcards

Distance Limitations for Direct Feeding

Distance Limitations for Direct Feeding

Signup and view all the flashcards

Protection Against Surges

Protection Against Surges

Signup and view all the flashcards

CIU-OC Communication

CIU-OC Communication

Signup and view all the flashcards

Communication Failure Handling

Communication Failure Handling

Signup and view all the flashcards

What safety standard must the EI system comply with?

What safety standard must the EI system comply with?

Signup and view all the flashcards

Who validates the EI system's software?

Who validates the EI system's software?

Signup and view all the flashcards

Who verifies the yard application software?

Who verifies the yard application software?

Signup and view all the flashcards

What documentation needs to be submitted for approval?

What documentation needs to be submitted for approval?

Signup and view all the flashcards

What must be documented after system modification?

What must be documented after system modification?

Signup and view all the flashcards

What software engineering standard should be followed for EI?

What software engineering standard should be followed for EI?

Signup and view all the flashcards

What is the significance of the CENELEC standard?

What is the significance of the CENELEC standard?

Signup and view all the flashcards

Why is documentation of changes vital?

Why is documentation of changes vital?

Signup and view all the flashcards

VDU Communication Status Indication

VDU Communication Status Indication

Signup and view all the flashcards

EI.OFC Cable

EI.OFC Cable

Signup and view all the flashcards

RGB Indication

RGB Indication

Signup and view all the flashcards

Yard Layout Display

Yard Layout Display

Signup and view all the flashcards

Field Equipment Status Display

Field Equipment Status Display

Signup and view all the flashcards

Hot Standby VDU

Hot Standby VDU

Signup and view all the flashcards

VDU Power Supply

VDU Power Supply

Signup and view all the flashcards

LCD Indication Panels

LCD Indication Panels

Signup and view all the flashcards

What documentation does the manufacturer need to provide?

What documentation does the manufacturer need to provide?

Signup and view all the flashcards

Who is responsible for verifying the safety and reliability of the system?

Who is responsible for verifying the safety and reliability of the system?

Signup and view all the flashcards

Why are certifications from an independent safety assessor important?

Why are certifications from an independent safety assessor important?

Signup and view all the flashcards

What are MTBF and MTBWSF?

What are MTBF and MTBWSF?

Signup and view all the flashcards

What is a cable plan in the context of an electronic interlocking system?

What is a cable plan in the context of an electronic interlocking system?

Signup and view all the flashcards

What are type tests?

What are type tests?

Signup and view all the flashcards

Visual inspection test

Visual inspection test

Signup and view all the flashcards

Insulation Resistance Test

Insulation Resistance Test

Signup and view all the flashcards

Card-level functional tests

Card-level functional tests

Signup and view all the flashcards

Fail-safety Test

Fail-safety Test

Signup and view all the flashcards

System level functional test

System level functional test

Signup and view all the flashcards

System Diagnostics Test

System Diagnostics Test

Signup and view all the flashcards

Environmental/climatic tests

Environmental/climatic tests

Signup and view all the flashcards

Cross Acceptance

Cross Acceptance

Signup and view all the flashcards

Long Term Spare Part Availability

Long Term Spare Part Availability

Signup and view all the flashcards

EI Technology Training

EI Technology Training

Signup and view all the flashcards

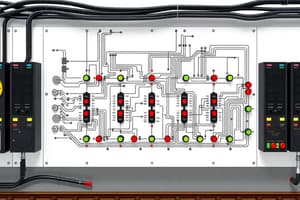

Test & Repair Facility

Test & Repair Facility

Signup and view all the flashcards

Annual Repair Contract

Annual Repair Contract

Signup and view all the flashcards

Certificates of Type Tests

Certificates of Type Tests

Signup and view all the flashcards

Procedure Order for Cross Acceptance/Approval

Procedure Order for Cross Acceptance/Approval

Signup and view all the flashcards

Continuous Support Requirement

Continuous Support Requirement

Signup and view all the flashcards

Study Notes

Document Information

- Document Number: RDSO/SPN/203/2011

- Document Title: SPECIFICATION FOR ELECTRONIC INTERLOCKING FOR BIG YARDS

- Version Number: 1

- Date Effective: 13/09/2011

- Number of Pages: 24

- Prepared By: SE/Signal

- Checked By: DD/Signal-III

- Issued By: Director/Signal-III

Scope

- Covers Electronic Interlocking (EI) for big yards

- Primarily for stations with >200 routes, and high reliability requirements

- EI can also be used in stations with fewer routes and many signaling input/output functions

Applicable/Reference Documents

- Various Indian Railway Standards (IRS) and RDSO specifications are referenced

- Includes standards relating to interlocking systems, electrical signaling, safety, reliability, EMC, and environmental testing

Terminology

- Definitions as per latest versions of IRS: S23 and RDSO/SPN/144 are used

Abbreviations

- Many abbreviations, such as CIU (Central Interlocking Unit), AFTC (Audio Frequency Track Circuit), ATP (Automatic Train Protection), etc., are defined

Functional Requirements

- Meets station's interlocking requirements (per approved plan and selection table)

- Includes cascaded signal control

- Provides audio-visual alarms for various situations

Technical Requirements

- Microprocessor-based interlocking equipment

- Reads yard inputs, processes, and generates outputs

- Provides fast response time (under 5 seconds) for complex routes

- Complies with Indian Railways standards, such as Signal Engineering Manual (SEM) & G&SR

System Architecture

- Two out of two or two out of three hardware architectures with identical or diverse software options are supported

- Redundancy is incorporated into the design for fault tolerance

Software Requirements

- Executive software defines system functionality

- Application software contains station-specific logic

Object Controller

- Processor-based, communicates with the Central Interlocking Unit (CIU)

- Drives field gears (points, signals, relays)

- Implements fail-safe operation

Control Terminal

- Includes a VDU (Visual Display Unit) monitor displaying yard status

- Redundant hot standby mode is available

- Multiple screens, if required, can show separate sections of the yard

- Includes communication with Central Interlocking Unit and the Object Controllers

- Uses Optical Fiber Cable (OFC) with isolators between systems

Protection Systems

- Shields from electromagnetic and electrostatic interference

- Includes provisions for short-circuit and overvoltage protection and surge protection

Safety Requirements

- Conforms to CENELEC SIL-4 standards for safety-critical applications, including software and hardware

- Meets international safety standards if a different standard is used

- Includes validation from an independent safety assessor, including software validation

Maintenance Aids

- Includes a maintenance terminal (MT)

- MT provides monitoring, storage, and displays of recorded events

- MT is connected to the interlocking through OFC for data transfer and diagnostics

Information/Documents

- Manufacturers must provide detailed specifications including design approaches, software details, and environmental/safety data

- Includes details such as installation, power requirements, components, test equipment, and maintenance aids.

Warranty and Availability Requirements

- Three-year warranty from equipment commissioning

- Ensure high system availability: 99.98% or better

Tests and Requirements

- Requirements for various types of tests, such as visual inspection, insulation resistance, functional and system-level tests

- Detailed procedures for each test stage

Acceptance Tests

- Tests are conducted to ensure compliance with the specifications

- Acceptance tests are conducted on a specific piece of equipment, for a full system, or a complete section

Quality Assurance

- Robust quality assurance measures are employed throughout the design, production, and testing phases

- Documentation of the quality assurance procedures is a required part of the submission.

Plant and Machinery

- Includes requirements for essential equipment for the installation and management

- Outsourced resources are permitted if approved by the RDSO

Packing

- Packing specifications that ensure a secure transportation process are included

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.