Podcast

Questions and Answers

In the context of drill bit sizing, what is a key characteristic of the shift in size increments as bit sizes increase?

In the context of drill bit sizing, what is a key characteristic of the shift in size increments as bit sizes increase?

- The size increment remains constant, ensuring consistent precision across all sizes.

- The size increment increases, leading to larger jumps in size as the bits get bigger. (correct)

- The size increment alternates between metric and imperial standards.

- The size increment decreases linearly to maintain a consistent percentage change.

For general applications, what is the common practice when selecting the first lettered drill size for a nominal bolt diameter?

For general applications, what is the common practice when selecting the first lettered drill size for a nominal bolt diameter?

- Choose the first lettered drill size larger than the nominal bolt diameter. (correct)

- Select the lettered drill size that is smaller than the nominal bolt diameter for an interference fit.

- Use the drill size that matches the nominal bolt diameter exactly to ensure a tight fit.

- Select a drill size based on the material, not the nominal diameter.

What does 'tolerance' refer to in the context of manufacturing standards?

What does 'tolerance' refer to in the context of manufacturing standards?

- The ideal dimension of a part before manufacturing.

- The degree of tightness or looseness between mating parts.

- The intentional difference between the sizes of mating parts.

- The maximum acceptable manufacturing error. (correct)

What is the primary purpose of a clearance fit in mechanical engineering?

What is the primary purpose of a clearance fit in mechanical engineering?

In the context of force fits, what is the most accurate method for assembling components?

In the context of force fits, what is the most accurate method for assembling components?

Why is it critical to maintain alignment during the assembly of force fits?

Why is it critical to maintain alignment during the assembly of force fits?

What is the coefficient of linear expansion used for when determining temperatures for shrink fits?

What is the coefficient of linear expansion used for when determining temperatures for shrink fits?

In aircraft inspection, what does 'bow' refer to?

In aircraft inspection, what does 'bow' refer to?

Regarding metric drill bit sizes, which increment is LEAST commonly available?

Regarding metric drill bit sizes, which increment is LEAST commonly available?

What is the primary purpose of using a lubricant, such as white lead and lard oil, when assembling force fits?

What is the primary purpose of using a lubricant, such as white lead and lard oil, when assembling force fits?

Why is interchangeability of parts important in mass production?

Why is interchangeability of parts important in mass production?

When is a unilateral tolerance applied to a dimension?

When is a unilateral tolerance applied to a dimension?

What factor should be considered to determine proper allowance for a force fit?

What factor should be considered to determine proper allowance for a force fit?

What is the significance of the coefficient of linear expansion in shrink fits?

What is the significance of the coefficient of linear expansion in shrink fits?

In the context of metric drill bit sizing, which increment is the MOST commonly available?

In the context of metric drill bit sizing, which increment is the MOST commonly available?

What distinguishes standard-tolerance bolts from close-tolerance bolts?

What distinguishes standard-tolerance bolts from close-tolerance bolts?

What is the primary criterion for a running fit?

What is the primary criterion for a running fit?

For aircraft inspection, what is the term 'travel' used to describe?

For aircraft inspection, what is the term 'travel' used to describe?

What is the key characteristic of a transition fit?

What is the key characteristic of a transition fit?

What is a characteristic of jobs performed on parts assembled using press fits?

What is a characteristic of jobs performed on parts assembled using press fits?

Which statement accurately describes allowances in the context of fits?

Which statement accurately describes allowances in the context of fits?

Which factor is MOST critical when considering 'shrinkage allowance' during shrink fitting?

Which factor is MOST critical when considering 'shrinkage allowance' during shrink fitting?

What is the primary function of 'freeze fitting' during component assembly?

What is the primary function of 'freeze fitting' during component assembly?

When is the use of metric drill bit sizes most common?

When is the use of metric drill bit sizes most common?

What is a driving fit?

What is a driving fit?

Why is it important to ensure that the contacting surfaces of both members be free of grit when assembling force fits?

Why is it important to ensure that the contacting surfaces of both members be free of grit when assembling force fits?

What does 'play' refer to in the context of aircraft inspection?

What does 'play' refer to in the context of aircraft inspection?

How are drill bit sizes typically represented on the bits themselves?

How are drill bit sizes typically represented on the bits themselves?

What is the purpose of using a heavy lubricant, such as white lead and lard oil, when assembling force fits?

What is the purpose of using a heavy lubricant, such as white lead and lard oil, when assembling force fits?

Why are parts manufactured to an acceptable size within a specified tolerance range in mass production?

Why are parts manufactured to an acceptable size within a specified tolerance range in mass production?

Flashcards

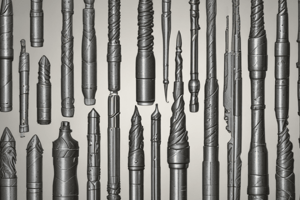

What are drill bits?

What are drill bits?

Cutting tools used to create holes, almost always of circular cross-section, by rotation.

Number & letter drill sizes

Number & letter drill sizes

Sizes range from size 80 (smallest) to size 1 (largest). Followed by letter gauge size A (smallest) to size Z (largest).

Jobber-length drills

Jobber-length drills

The most common type of drill; flute length is 9-14 times the drill diameter.

Fits and clearances

Fits and clearances

Signup and view all the flashcards

Tolerance

Tolerance

Signup and view all the flashcards

Allowance

Allowance

Signup and view all the flashcards

Clearance fit

Clearance fit

Signup and view all the flashcards

Interference fit

Interference fit

Signup and view all the flashcards

Unilateral tolerance

Unilateral tolerance

Signup and view all the flashcards

Travel (inspection)

Travel (inspection)

Signup and view all the flashcards

Fractional Sizes (Drill Bits)

Fractional Sizes (Drill Bits)

Signup and view all the flashcards

Metric Sizing (Drill Bits)

Metric Sizing (Drill Bits)

Signup and view all the flashcards

Close-Tolerance Bolt Holes

Close-Tolerance Bolt Holes

Signup and view all the flashcards

Gauge Size Drill Bits

Gauge Size Drill Bits

Signup and view all the flashcards

Standard-Tolerance Bolts

Standard-Tolerance Bolts

Signup and view all the flashcards

Close-Tolerance Bolts

Close-Tolerance Bolts

Signup and view all the flashcards

Running Fits

Running Fits

Signup and view all the flashcards

Sliding Fits

Sliding Fits

Signup and view all the flashcards

Bilateral Tolerances

Bilateral Tolerances

Signup and view all the flashcards

Limits of Size

Limits of Size

Signup and view all the flashcards

Basic Size

Basic Size

Signup and view all the flashcards

Upper & Lower Limit of Size

Upper & Lower Limit of Size

Signup and view all the flashcards

Heat and Shrink Fits

Heat and Shrink Fits

Signup and view all the flashcards

Driving Fit

Driving Fit

Signup and view all the flashcards

Force Fit

Force Fit

Signup and view all the flashcards

Bow (inspection)

Bow (inspection)

Signup and view all the flashcards

Twist (inspection)

Twist (inspection)

Signup and view all the flashcards

Shrink Fit

Shrink Fit

Signup and view all the flashcards

Study Notes

- Drill bits are cutting tools for creating holes, typically with a circular cross-section.

- They are attached to a drill, which powers them to cut through materials via rotation.

- The drill grasps the upper end of the bit using a shank in the chuck.

Drill Bit Sizes

- Standard sizes exist and are listed in comprehensive drill bit and tap size charts which include metric- and imperial-sized information.

- Some specialized drill bits can create holes with non-circular cross-sections.

- Fractional inch and gauge drill bit sizes are commonly used in the United States.

- Metric drill bit sizes are more common in nearly all other countries and areas but designs from the United States may require other types.

- British standards replaced gauge size drill bits with metric sizes of drill bits in the United Kingdom in 1959.

Metric Sizing

- Bits at 1 mm size increments are the most commonly available.

- Sets of bits may be found in the following increments:

- 1 mm increments in a market stall

- 0.5 mm increments at any hardware store

- 0.1 mm increments at any engineers' store

- Sets are not commonly available in smaller size increments, except for drill bits below 1-mm diameter.

- Drill bits of the less routinely used sizes, such as 2.55 mm, must be ordered from a specialist drill bit supplier.

- Metric dimensioning is routinely used for drill bits of all types.

- BS 328 specifically applies only to twist drill bits.

- Forstner bits may contain sizes like 10 mm, 15 mm, 20 mm, 25 mm and 30 mm diameter cutters.

Number and Letter Gauge Drill Bit Sizes

- Number drill bit gauge sizes range from size 80 (the smallest) to size 1 (the largest).

- This is followed by letter gauge size A (the smallest) to size Z (the largest).

- ASME B94.11M twist drill standard specifies sizes as small as size 97, sizes smaller than 80 are rarely encountered in practice.

- Number and letter sizes are commonly used for twist drill bits rather than other drill forms.

- Number and letter gauge drill bits are still in common use in the United States and, to a lesser extent, the United Kingdom, where they have largely been superseded by metric sizes.

- Other countries which formerly used the number series have mostly abandoned these in favor of metric sizes.

Fractional Sizes

- ANSI B94.11M-1979 sets size standards for jobber-length straight shank twist drill bits sized from 1/64 in. to 1 in., in 1/64-in. increments.

- For Morse taper shank drill bits, the standard continues in 1/64-in. increments up to 1 3/4 in., then 1/32-in. increments up to 2 1/4 in., 1/16-in. increments up to 3 in., 1/8-in. increments up to 3 1/4 in., and a single 1/4-in. increment to 3 1/2 in.

- The size increment between drill bits becomes larger as bit sizes become smaller. It is 100% for the step from 1/64 to 1/32, but a much smaller percentage between 1 47/64 and 1 3/4.

- Drill bit sizes are written down on paper and etched onto bits as irreducible fractions.

- Instead of 78/64 in. or 1 14/64 in., the size is noted as 1 7/32 in.

- The next page contains a chart providing the decimal-fraction equivalents that are most relevant to fractional-inch drill bit sizes (that is, 0 to 1 by 64ths).

- Decimal places for 0.25, 0.5 and 0.75 are shown to thousandths (0.250, 0.500, 0.750), which is how machinists usually think about them: 'two-fifty', 'five hundred', ‘seven-fifty'.

Jobber-Length Drills

- The most common type of drill.

- The length of the flutes is between nine and 14 times the diameter of the drill, depending on the drill size.

- A 1/2-in. (12.7-mm) diameter drill can drill a hole 4 1/2 in. (114.3 mm) deep.

- A 1/8-in. (3.2-mm) diameter drill can drill a hole 1 5/8 in. (41.3 mm) deep.

- Extended reach or long series drills are commonly called aircraft length from their original use in manufacturing riveted aluminium aircraft.

- For bits thicker than a minimum size such as 1/8 in., they are available in fixed lengths such as 6, 8, 12 or 18 in. rather than the progressive lengths of jobber drills.

- Centre drills are available with two different included angles: 60° is the standard for drilling centre holes but 90° is also common and used when locating holes prior to drilling with twist drills.

- To eliminate friction during fitting, close-tolerance bolts can be placed in a freezer prior to fitment.

- Standard-tolerance bolts are manufactured to +0.000 to -0.0055 in. of the diameter's nominal size.

- Close-tolerance bolts are manufactured to +0.000 to +0.0005 in. of the diameter's nominal size.

- Bolt holes of primary connecting elements have close tolerances.

- For general application, it is generally permissible to use the first lettered drill size larger than the nominal bolt diameter except where an AN hex bolt is a light drive fit (reamed).

- A light drive fit is defined as an interference fit and is approximately 0.0006 in. for a 5/8-in. diameter bolt.

- For a 3/8-in. bolt (0.375 in.), it would be acceptable to have a V letter drill for the hole (0.377 in.) or 0.002 in. clearance.

Tolerance and Allowance

- Allow mass-produced parts to fit within limits, which is a cost-effective production method and ensures parts are interchangeable.

- If a hole is acceptable between the limits of 1.000 in. (low limit) and 1.0015 in. (high limit), the allowable manufacturing error of 0.0015 in. could be tolerated, which is the tolerance.

- Nominal Dimension Hole 1.000 in. -0.000 in. +0.0015 in.

- The allowance represents the tightest permissible fit for proper construction.

- Allowance can be negative (shrink fit).

- The term fit refers to the degree of tightness or looseness between mating parts.

- Mating of mechanical components is classified into three broad classes:

- Clearance fits

- Interference fits

- Transition fits

- Each main class is further sub-divided into several types of fit, and each type is classified by a letter symbolising the shaft that produces the fit using a standard hole.

- Where it is necessary to have movement between parts, the hole must be larger than the male component (shaft) to provide a suitable clearance between them.

Running Fit

- Running fits have a clearance between mating surfaces sufficient to allow one item to rotate freely within the other without danger of seizing.

Sliding Fit

- Sliding fits have a smaller clearance than running fits and are designed for use when the mating surfaces have to slide but not rotate.

- Interference fit is when no movement is possible after assembly, the inner part being larger than the part into which it fits.

- When parts are required to fit tightly together, such as when a shaft is required to fit into a hole in a boss, the outside of the shaft must be slightly larger than the hole.

Driving Fit

- Driving fit is when a shaft is slightly larger than the hole and the allowance is such that the parts can be assembled by driving.

Force Fit

- In a force fit, the parts have to be forced together, usually by presses, with interference larger than a driving fit.

Shrink Fit

- Needed when the parts being joined are to be held in place permanently.

- The outer member can be heated or the shaft can be cooled with interference being greater than force fit.

Transition Fit

- An intermediate type between interference and clearance fits where the mating parts are almost the same size.

- Selective assembly of pieces on either side of the allowance can determine if the fit will be a clearance or interference fit

Fits Classified by Assembly Method

- Running Fit: The shaft is designed to rotate in the hub.

- Sliding Fit: Parts can be assembled by hand with slight pressure.

- Push Fit: Parts can be assembled with a little more pressure than a sliding fit.

- Driving Fit: Parts can be assembled by cushioned blows with a hammer.

- Force Fit: Heavy interference between the parts requiring a hydraulic press for assembly.

- Shrink Fit: To avoid damage, the outer part is expanded by heating, and in extreme cases, the inner part may be shrunk by severe cooling.

- Heat/Shrink Fits (Interference Fit): Turbine wheel to turbine shaft assembly, bearings to shafts and gears, sleeves to cases are examples and these allow for the assembly of components.

- Press Fits (Transition Fit): Bushings, bearings, and sleeves. The turbine shaft bearing is normally pressed onto the turbine shaft assembly. The turbine assembly tie bolts are a press type fit which are normally assembled by applying a predetermined torque to the tie bolt nuts to draw the bolt home into the turbine wheel bolt holes.

- The spacers between the turbine wheels are normally a light press type fit.

- Clearance Fit: Turbine/compressor blades to discs, case split line bolts, and piston to cylinder. The turbine blades are a clearance type fit in which the blades are inserted into the turbine wheels by hand and just slide into the fur tree.

Interchangeability

- Parts are manufactured to an acceptable size with a specified tolerance range, so all of the parts can fit a single mating part with the same type of fit.

- Interchangeability of parts is important in mass production because it enables:

- Reduction in costs

- Simplicity in fitting and assembly

- Quick replacement of worn assemblies or single parts of an assembly.

- These techniques are widely used throughout the automotive, engineering and aerospace industries.

Tolerance Types

- Every dimension on a drawing has a tolerance and may be expressed by specific limits of size applied directly to the dimension or in a general tolerance note.

- Three types of tolerances can be applied: unilateral, bilateral and limits of size.

- A unilateral tolerance means variation is permitted only in one direction from the specified dimension.

- A bilateral tolerance means variation is permitted in both directions from the specified dimension.

- Limits of size are the extremes of size allowed for a dimension: the maximum allowable size and the minimum allowable size.

- Basic size is the size about which the limits of a particular fit are fixed and may also be referred to as the nominal size.

- Upper limit of size (ULS) is the largest size permitted by a toleranced dimension; a common example is 20.50 ± 0.25 so that the ULS = 20.75

- Lower limit of size (LLS) is the smallest size permitted by a toleranced dimension; a common example is 20.50 ± 0.25 so that the LLS = 20.25

- Tolerance is the total amount of variation permitted by the limits of the dimension, expressed as the mathematical difference between the upper and lower limits of size; a common example is 20.50 ± 0.25 so that the tolerance = 0.50

- Allowance is the intentional difference between the sizes of mating parts to provide the required class of fit.

Maintenance

- During maintenance, mating parts are measured to determine if they are suitable for further service.

- Common areas of wear are shafts and bolts acting as hinge pins and elongation of holes in moving controls.

- A press fit or interference fit exists when the male member is larger than the female member

Processes During Press Fits

- Force

- Shrink

- Freeze

- Examples of applications: a bush in a casing, railway wheel on hub, crankshaft sections.

- Pins, journals and webs are often assembled without keying, with interference fitting.

Assembly Factors

- The interference in most cases is not allowed to vary much, excess can distort the assembly and too little can achieve insufficient grip.

- The most accurate method of assembling a force fit is by hydraulic press to prevent damage, using a light lever or screw press for smaller jobs

- Mass, kind/quality of material, size of work determine the suitable allowance for a forced fit which can be found in engineering handbooks as a guide only.

Preparation

- Contacting surfaces must be free of grit.

- Male and female axes must be aligned, which is achieved using an assembly arbour.

- Tests show the best grip is achieved with perfectly smooth mating surfaces that are free from surface film.

- Before assembling a heavy lubricant is applied such as white lead and lard oil mixed to paint to prevent possible abrasion of the surfaces.

- Shrink fitting uses thermal expansion/contraction to use interference effects by heating an outer (female) component. Factors that determine shrinkage allowance are construction, type of material and form or shape. The thickness of the web with uneven thickness is liable to fracture by concentrating the stretching of the metal at the weakest point.

Shrink Fit Temperatures

- The factors of metal thickness is the most important but the distribution affects results.

- Heat/cooldown is given by the temperature, where the method and calculation depends on the expansion required and the coefficient of linear expansion of the metal.

- Coefficient of linear expansion is the increase in unit length of any section of metal in any direction for an increase in temperature of 1 °C. The total required expansion in diameter consists of the allowance for shrinkage plus an amount for clearance

Thermal Expansion Coefficient

- Aluminium 0.00002/C

- Cast iron 0.00001/C

- Steel 0.000011/C

- Nickel steel 0.000012/C.

Methods

- In hot water, oil or metal baths

- Steam

- Air and gas, oxygen and gas hand torches

- Oil, gas or electric furnaces

- Electrical resistance heating

- Electric induction heating

- Immersion in liquids cooled by ice, dry ice or refrigeration

- Cooling in a refrigerator

- Packing in dry ice

- Immersion in liquid air or liquid nitrogen

- Freeze fitting is cooling to reduce installation/fitting friction.

Considerations

- Press fitting with heat/cold has safety risks so consider assembly/dismantling of components with: free contacting surfaces, alignment and use of PPE

Aircraft Inspection

- Aircraft inspection limits are the bounds of any of the following:

- travel

- wear

- play

- clearance

- bow

- twist.

- Travel is the distance between the extreme positions of a mechanism between fully extended and fully retracted.

- Play is the relative movement between two aircraft parts.

- Bow is the amount that a side of a surface deviates from being straight.

- A Dial Test Indicator is used to inspect shafts.

- Feeler gauges and a straight-edge are used for a compressor blade.

- Twist is the rotation of a shaft or component about its longitudinal axis.

- A shaft has a reference line that is compared to measures or limits.

- Wear is the amount of material loss due to friction, rotation or any other form of movement on a part/component.

- Some of the methods of checking for wear:

- Micrometer

- Vernier gauge

- Dial test indicator

- Go/no-go gauge

- Feeler gauges.

- Common methods listed in manufacturer's manuals: Visual, micrometers, verniers, dial test indicators,dye penetrant inspection, eddy current inspection, magnetic particle inspection, radiographic (X-ray) inspection and ultrasonic inspection.

- At all times, follow the manufacturer's inspection requirements.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.