Podcast

Questions and Answers

What is the characteristic of a Long Series Parallel Shank Twist Drill?

What is the characteristic of a Long Series Parallel Shank Twist Drill?

- It is used for centre hole drilling.

- It has a parallel shank with a diameter similar to the cutting end. (correct)

- It has a smaller diameter at the drill point.

- It has a tapered shank.

Taper Shank Twist Drills are used for deeper holes or extended reach applications.

Taper Shank Twist Drills are used for deeper holes or extended reach applications.

False (B)

What is the purpose of Oil Tube Drills?

What is the purpose of Oil Tube Drills?

Drilling deep holes.

Core Drills are used for enlarging ___________ holes.

Core Drills are used for enlarging ___________ holes.

Match the type of drill with its characteristic.

Match the type of drill with its characteristic.

What is the point angle of a drill used for general-purpose drilling?

What is the point angle of a drill used for general-purpose drilling?

Core Drills can originate a hole in solid material.

Core Drills can originate a hole in solid material.

What is the cutting action of a Core Drill similar to?

What is the cutting action of a Core Drill similar to?

What is a twist drill primarily used for?

What is a twist drill primarily used for?

Carbide drill bits are made from high-speed steel.

Carbide drill bits are made from high-speed steel.

What are the materials used to manufacture twist drills?

What are the materials used to manufacture twist drills?

Drill bits are available to suit characteristics of various types of metals, including ____________.

Drill bits are available to suit characteristics of various types of metals, including ____________.

What is the primary application of drill bits?

What is the primary application of drill bits?

Twist drills are only used for drilling holes in metal.

Twist drills are only used for drilling holes in metal.

Match the following materials with their uses in drill bit manufacturing:

Match the following materials with their uses in drill bit manufacturing:

What is the purpose of grinding the diameter and point of a twist drill?

What is the purpose of grinding the diameter and point of a twist drill?

What is a characteristic of small hole saws?

What is a characteristic of small hole saws?

A bi-metal hole saw can only make holes in wood.

A bi-metal hole saw can only make holes in wood.

What is the main difference between a straight shank twist drill and a taper shank twist drill?

What is the main difference between a straight shank twist drill and a taper shank twist drill?

A ______________________ drill has two parallel shanks of approximately the same diameter as the cutting end.

A ______________________ drill has two parallel shanks of approximately the same diameter as the cutting end.

What is the purpose of a Centre Drill?

What is the purpose of a Centre Drill?

Match the following drill types with their characteristics:

Match the following drill types with their characteristics:

An Oil Tube Drill is used for drilling large holes.

An Oil Tube Drill is used for drilling large holes.

What is the main difference between a Sub Series Parallel Shank Twist Drill and a Long Series Parallel Shank Twist Drill?

What is the main difference between a Sub Series Parallel Shank Twist Drill and a Long Series Parallel Shank Twist Drill?

Flashcards are hidden until you start studying

Study Notes

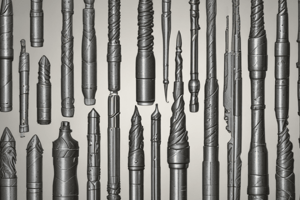

Types of Twist Drills

- Long Series Parallel Shank Twist Drill: useful for deeper holes or extended reach applications, has two helical flutes with a parallel shank approximately the same diameter as the cutting end.

- Taper Shank Twist Drill: has two helical flutes with a tapered shank for holding and driving the drill.

- Taper Shank Core Drill (Three or Four Fluted): designed for enlarging cored, punched, or drilled holes, cannot originate a hole in solid material, cutting action similar to a rose reamer, used as a rough reamer.

- Oil Tube Drill: used for drilling deep holes, oil tubes run lengthwise spirally through the body and carry the oil directly to the cutting edges.

- Centre Drills: straight shank, two fluted twist drills used when centre holes are drilled on the ends of a shaft.

Characteristics of Twist Drills

- Point angle of a general-purpose drill: 118 °, can be increased or decreased depending on the material it has to cut.

- Twist drill is an end cutting tool, formed by twisting a flat piece of tool steel longitudinally for several revolutions, then grinding the diameter and point.

Applications of Drill Bits

- Drill bits are manufactured to drill holes in different materials: wood, metal, plastic, ceramic tile, porcelain, concrete.

- Drill bits are available to suit characteristics of various types of metals: steel, aluminium, copper, cast iron, sheet metal.

Material Used in Drill Bits

- One-piece construction: high-speed steel (HSS) and carbide drill bits.

- Carbide materials: carbide steel (carbon steel), carbide tungsten, carborundum (carbon silicon), hard like diamond.

- Two-piece construction: cutting portion made of high-speed steel, and shank.

Types of Drill Bits

- Hole Saw: includes a built-in shank rather than a pilot bit, can make holes in both wood and metal.

- Bi-metal hole saw: can make holes in both wood and metal.

Classification of Twist Drills

- Classified according to the type of shank: straight or parallel shank, and taper shank.

- Further sub-classification can be done according to the length of the flute and overall length of the drill.

- Sub-series parallel shank twist drill: shortened type of parallel shank twist drill, with shortening occurring on the flute length, suitable for drilling in confined spaces or when a shorter flute length is required.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.