Podcast

Questions and Answers

What is the maximum allowed peripheral displacement from the central axis of a bur, known as eccentricity or run-out?

What is the maximum allowed peripheral displacement from the central axis of a bur, known as eccentricity or run-out?

- 0.05mm

- 0.1mm

- 0.025mm (correct)

- 0.01mm

What is the purpose of crosscuts on fissure burs?

What is the purpose of crosscuts on fissure burs?

- To increase cutting effectiveness at high speeds

- To obtain adequate cutting effectiveness at low speeds (correct)

- To reduce heat generation during cutting

- To improve bur longevity

Which of the following bur materials is prone to rust?

Which of the following bur materials is prone to rust?

- Ceramic

- Steel (correct)

- Titanium

- Carbide

What is the term for the direct measurement of symmetry of the bur head?

What is the term for the direct measurement of symmetry of the bur head?

What is the primary advantage of a negative rake angle on a bur?

What is the primary advantage of a negative rake angle on a bur?

Which of the following bur design features is used for finishing and producing a smoother surface?

Which of the following bur design features is used for finishing and producing a smoother surface?

What is the result of excessive eccentricity or run-out in a bur?

What is the result of excessive eccentricity or run-out in a bur?

What is the term for the rate of tooth structure removal during cutting?

What is the term for the rate of tooth structure removal during cutting?

Which of the following is a disadvantage of carbide burs?

Which of the following is a disadvantage of carbide burs?

What is the purpose of a latch-type shank design in burs?

What is the purpose of a latch-type shank design in burs?

What is the primary advantage of high speed hand pieces in operative dentistry?

What is the primary advantage of high speed hand pieces in operative dentistry?

Which of the following types of rotary tools is most effective for extra-coronal tooth preparations?

Which of the following types of rotary tools is most effective for extra-coronal tooth preparations?

What is the primary mechanism of cutting for dental abrasive tools?

What is the primary mechanism of cutting for dental abrasive tools?

What is the primary advantage of carbide burs over diamond points?

What is the primary advantage of carbide burs over diamond points?

What determines the surface finish of a tooth preparation?

What determines the surface finish of a tooth preparation?

What is the primary purpose of the shank design in a dental bur?

What is the primary purpose of the shank design in a dental bur?

Which material is commonly used for dental burs?

Which material is commonly used for dental burs?

What determines the cutting effectiveness of a dental bur?

What determines the cutting effectiveness of a dental bur?

What is the primary advantage of using diamond points for beveling enamel margins?

What is the primary advantage of using diamond points for beveling enamel margins?

What is the primary purpose of the cross-cut design in a dental bur?

What is the primary purpose of the cross-cut design in a dental bur?

Flashcards

Rotary Instrument Shank

Rotary Instrument Shank

Part of a rotary instrument that fits into a handpiece, transferring rotary motion for cutting.

Plain Blades (Gross Cutting)

Plain Blades (Gross Cutting)

Burs with 6-8 blades designed for efficient, gross material removal, but leave a rougher surface.

Plain Blades (Finishing)

Plain Blades (Finishing)

Burs with over 12 blades designed for creating smoother surfaces during finishing procedures.

Rake Angle

Rake Angle

Signup and view all the flashcards

Crosscut Burs

Crosscut Burs

Signup and view all the flashcards

Latch-Type Shank

Latch-Type Shank

Signup and view all the flashcards

Friction-Grip Shank

Friction-Grip Shank

Signup and view all the flashcards

Steel Burs

Steel Burs

Signup and view all the flashcards

Carbide Burs

Carbide Burs

Signup and view all the flashcards

Eccentricity (Run-out)

Eccentricity (Run-out)

Signup and view all the flashcards

Cutting Effectiveness

Cutting Effectiveness

Signup and view all the flashcards

Cutting Efficiency

Cutting Efficiency

Signup and view all the flashcards

Source of Power

Source of Power

Signup and view all the flashcards

Handpiece

Handpiece

Signup and view all the flashcards

Cutting Tool

Cutting Tool

Signup and view all the flashcards

Low-Speed Handpiece

Low-Speed Handpiece

Signup and view all the flashcards

High-Speed Handpiece

High-Speed Handpiece

Signup and view all the flashcards

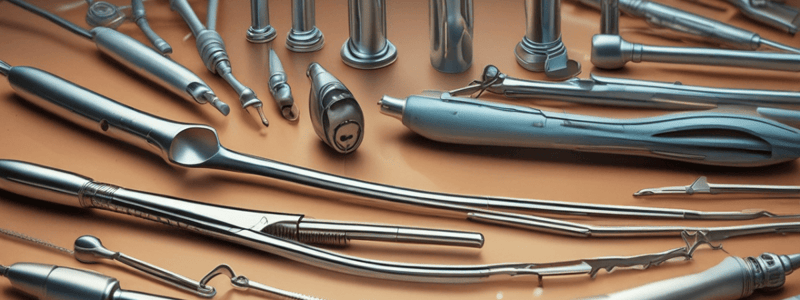

Dental Cutting Tools (Burs)

Dental Cutting Tools (Burs)

Signup and view all the flashcards

Dental Abrasive Tools (Stones)

Dental Abrasive Tools (Stones)

Signup and view all the flashcards

Carbide Bur Uses

Carbide Bur Uses

Signup and view all the flashcards

Study Notes

Rotary Instruments for Tooth Preparation

- Rotary instrument shank fits into a hand piece and accepts rotary motion, unlike shank in hand-cutting instruments.

- Shank connects power to cutting end, while grasp is done on the shaft.

Bur Design

- Plain blades: gross cutting (6-8 blades) for less smooth surface, and finishing (above 12 blades) for smoother surface.

- Rake angle: negative rake angle (rake face ahead of radius) minimizes fractures of cutting edge, increasing tool life.

Types of Burs

- Crosscuts: needed for fissure burs at low speeds, but not at high speeds to avoid rough surfaces.

- Shank design:

- Latch type

- Friction grip

Material

- Steel: main disadvantage is rust

- Carbide: main disadvantage is brittleness (breaks)

Eccentricity or Run-out

- Maximum displacement periphery from central axis is 0.025mm

- Causes: loss of efficiency, heat generation, discomfort to the patient, and cracks in enamel

- Related to precision of handpiece

Cutting Effectiveness and Efficiency

- Cutting effectiveness: rate of tooth structure removal (mm/min or mg/s)

- Cutting efficiency: percentage of energy actually producing cutting

Rotary System Components

- Source of power:

- Electric driven

- Air driven

- Hand piece:

- Low speed

- High speed

- Cutting tool:

- Dental bur

- Abrasive stone

Hand Pieces

- Low speed: < 200,000RPM

- High speed: 400,000RPM

- Advantages of high speed HP:

- Faster cutting with less pressure and vibration

- Reduced operating time

- Better control and ease of operation

- Longer instrument life

- Less patient apprehension

Rotary Tools

- Dental cutting tools (burs):

- Blades: cut by chipping action

- Dental abrasive tools (stones):

- Abrasive particles: cut by abrasion

- Carbide bur:

- Better for end cutting

- Produces lower heat generation

- Used for punch cuts, intracoronal tooth preparation, amalgam removal, and secondary retention features

- Diamond points:

- Produce more friction due to large surface area

- High heat generation

- Used for extra-coronal tooth preparations, beveling enamel margins on tooth preparations

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.