Podcast

Questions and Answers

What is the primary purpose of sealing peel-apart pouches?

What is the primary purpose of sealing peel-apart pouches?

- To reduce the weight of the instruments

- To make the instruments more accessible

- To make the packaging more appealing

- To ensure the product remains sterile after autoclaving (correct)

What type of pouch is used for Steam and Ethylene Oxide sterilization methods?

What type of pouch is used for Steam and Ethylene Oxide sterilization methods?

- Spunbond polyolefin pouch

- Paper pouch (correct)

- Tyvek pouch

- Plastic pouch

How much space should be left on each side of the package?

How much space should be left on each side of the package?

- About ¼ inch (correct)

- About ¾ inch

- About 1 inch

- About ½ inch

What is the purpose of removing excessive air from the pouch?

What is the purpose of removing excessive air from the pouch?

What type of instrument is typically packed in a peel pouch?

What type of instrument is typically packed in a peel pouch?

Why is it important to pack instruments with opened hinges?

Why is it important to pack instruments with opened hinges?

What is the recommended method for labeling pouches?

What is the recommended method for labeling pouches?

What is the purpose of using a heat sealer or self-seal?

What is the purpose of using a heat sealer or self-seal?

What type of material is used to make Tyvek pouches?

What type of material is used to make Tyvek pouches?

Why is transparency of the pouch important?

Why is transparency of the pouch important?

Flashcards

Assembly Area

Assembly Area

A designated area within the CSSD where surgical instruments are inspected for cleanliness, functionality, and any damage.

Clean Room Standards

Clean Room Standards

A controlled environment within the assembly area that meets specific air quality standards to prevent contamination. Air flows outward to maintain sterility.

Rigid Container

Rigid Container

A container designed to protect sterilized instruments from contamination. It's durable, lockable, and allows sterilization agents to penetrate.

Instrument Inspection

Instrument Inspection

Signup and view all the flashcards

Peel-Apart Pouch

Peel-Apart Pouch

Signup and view all the flashcards

Seal Pouch

Seal Pouch

Signup and view all the flashcards

Packing Instruments

Packing Instruments

Signup and view all the flashcards

Function Testing

Function Testing

Signup and view all the flashcards

Ergonomics Challenge

Ergonomics Challenge

Signup and view all the flashcards

Longer Cycle Time

Longer Cycle Time

Signup and view all the flashcards

Study Notes

Assembly Area and Environmental Requirements

- Assembly area is a clean area in the CSSD where surgical instruments are inspected for intactness, cleanliness, and functionality.

- The area must be designated and controlled to optimize the effect of the sterilization process and minimize the risk of contamination of the RMD sets.

- Ventilation in the inspection, assembly, and packing room meets clean room standards according to ISO 14644-1: 1999 Class 8 or other internationally accepted equivalent standard.

- The room must be maintained under positive pressure to ensure that the air flows outward instead of into the work area.

- The room must be maintained at a comfortable working temperature of 20–23°C and a relative humidity within the range 30–60%.

- All furniture in the area must be made of smooth non-porous, easy-to-clean materials.

- Environmental cleaning must follow policies and procedures approved by the hospital's infection control committee.

Rigid Containers

- Rigid containers are almost indestructible, providing sterility and customer reassurance if handled and maintained according to the manufacturer's instructions.

- Containers must be:

- Easily disassembled for cleaning, drying, and storage

- Suitable for the method of sterilization being used

- Compatible with the cleaning method and cleaning agent being used

- Suitable for the storage configuration

- Lockable, tamperproof, and non-resealable

- Packed in a manner that allows for penetration of the sterilizing agent

- Containers have filter and/or valve systems that are secure and must be in proper working order before sterilization.

- Filter plates must be examined for integrity before and after the sterilization process.

Disadvantages of Using Rigid Containers

- Create ergonomics challenge to those who lift them due to heaviness

- Require additional space to store them as they are larger than wrapped trays

- Longer cycle time may be required to avoid issues associated with excessively wet packs

- Entail extra effort since the containers must be cleaned between uses

- Potential risk of filter dislodge leading to instruments contamination

Packaging Materials

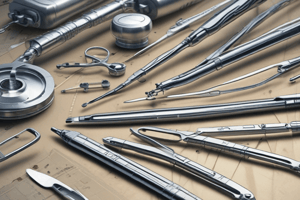

- Peel-apart pouches with a see-through front and paper backing are often used for single devices or small loads.

- Pouches come in reels of various sizes where both ends need to be sealed or as single forms of various sizes for self-seal.

- Peal pouches are used to pack small lightweight single instruments.

Inspection and Function Testing

- All surgical devices unloaded from the washer-disinfector must be inspected for cleanliness, stains, corrosion, cracks, breakage, and stiffness of movable parts before being placed in device sets.

- Devices should be checked under magnification because small pieces of bioburden or debris can otherwise be difficult to see.

- Each RMD from a set should be inspected separately.

- Critically inspect all areas of the devices, including box joints, serrations, and crevices, for cleanliness.

Packing and Sealing

- Peal pouches are used to pack small lightweight single instruments.

- Sealing peel-apart pouches is essential to ensure that the product remains sterile after autoclaving.

- Self-sealing pouches have an adhesive manufactured into the open end of the bag or plain top and either a heat sealing machine or autoclave tape is then required to create a seal.

- Recommended sealing temperatures and pressures, and other technical advice should be followed carefully.

- Identification of packed devices is easy because of the transparent plastic film.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz covers the important steps involved in the inspection, assembly, and packaging of surgical instruments in a clean area of the CSSD. Trained decontamination specialists and technicians play a critical role in ensuring the cleanliness and functionality of instruments before they are dispensed to OR rooms or clinics.