Podcast

Questions and Answers

EASY What is the purpose of cleaning the coupons after removal from the rack?

EASY What is the purpose of cleaning the coupons after removal from the rack?

- To handle the coupons with bare hands

- To ensure galvanic corrosion does not affect the results

- To remove system contaminants and prepare for weighing (correct)

- To remove the passive layer formed on the coupon

Why should coupons that have been in place for only a month not be compared to coupons in place for three months?

Why should coupons that have been in place for only a month not be compared to coupons in place for three months?

- Because the longer-term coupons may have undergone galvanic corrosion

- Because the most metal loss occurs in the first month as a passive layer forms (correct)

- Because the longer-term coupons are more susceptible to system contaminants

- Because the shorter-term coupons are less reliable

Why should you never handle coupons with bare hands?

Why should you never handle coupons with bare hands?

- To prevent oil, grease, or dirt from affecting the results (correct)

- To ensure the Teflon bolts are not damaged

- To ensure the coupon rack is not contaminated

- To prevent galvanic corrosion from affecting the results

What is the purpose of using Teflon bolts to hold the coupons in place?

What is the purpose of using Teflon bolts to hold the coupons in place?

What is the unit of measurement for the corrosion rate expressed in?

What is the unit of measurement for the corrosion rate expressed in?

What is the primary test conducted to determine condensate purity?

What is the primary test conducted to determine condensate purity?

What is the acceptable level of dissolved iron in a sample?

What is the acceptable level of dissolved iron in a sample?

How are direct amine measurements made?

How are direct amine measurements made?

What is the purpose of corrosion coupons?

What is the purpose of corrosion coupons?

What is the temperature requirement for taking a condensate sample?

What is the temperature requirement for taking a condensate sample?

Why are stainless steel lines used in sampling?

Why are stainless steel lines used in sampling?

What is the purpose of a continuous fluorometer?

What is the purpose of a continuous fluorometer?

Where should samples be taken from?

Where should samples be taken from?

MEDIUM What is the primary purpose of corrosion byproduct monitoring?

MEDIUM What is the primary purpose of corrosion byproduct monitoring?

What is the significance of throttling the sample flow at the outlet of the sampling system?

What is the significance of throttling the sample flow at the outlet of the sampling system?

What is the advantage of using corrosion coupons?

What is the advantage of using corrosion coupons?

Why are stainless steel lines used in sampling?

Why are stainless steel lines used in sampling?

What is the primary purpose of a chromatograph in condensate analysis?

What is the primary purpose of a chromatograph in condensate analysis?

How often should samples be taken for accurate analysis?

How often should samples be taken for accurate analysis?

What is the purpose of purging the sampling device?

What is the purpose of purging the sampling device?

What is the significance of cooling the sample to less than 32°C (90°F)?

What is the significance of cooling the sample to less than 32°C (90°F)?

What is the primary reason for weighing the coupons after cleaning and drying?

What is the primary reason for weighing the coupons after cleaning and drying?

What is the purpose of the passive layer that forms on the coupon?

What is the purpose of the passive layer that forms on the coupon?

What is the primary advantage of using Teflon bolts to hold the coupons in place?

What is the primary advantage of using Teflon bolts to hold the coupons in place?

What would be the result of handling coupons with bare hands?

What would be the result of handling coupons with bare hands?

What is the typical duration for which the coupons are immersed in the condensate?

What is the typical duration for which the coupons are immersed in the condensate?

HARD What is the primary reason why galvanic corrosion can affect the test results?

HARD What is the primary reason why galvanic corrosion can affect the test results?

What is the primary advantage of using Teflon bolts to hold the coupons in place?

What is the primary advantage of using Teflon bolts to hold the coupons in place?

What is the significance of the passive layer that forms on the coupon?

What is the significance of the passive layer that forms on the coupon?

What is the primary reason why the coupons are removed from the rack after 1 to 3 months?

What is the primary reason why the coupons are removed from the rack after 1 to 3 months?

What is the primary reason why the coupons are weighed after cleaning and drying?

What is the primary reason why the coupons are weighed after cleaning and drying?

What is the primary benefit of using a continuous fluorometer in condensate analysis?

What is the primary benefit of using a continuous fluorometer in condensate analysis?

Why are corrosion coupons only useful for estimating average corrosion rates?

Why are corrosion coupons only useful for estimating average corrosion rates?

What is the primary purpose of correlating corrosion byproduct monitoring with other tests?

What is the primary purpose of correlating corrosion byproduct monitoring with other tests?

What is the significance of ensuring an adequate flow of material occurs during sampling?

What is the significance of ensuring an adequate flow of material occurs during sampling?

What is the primary advantage of using corrosion coupons over other corrosion monitoring methods?

What is the primary advantage of using corrosion coupons over other corrosion monitoring methods?

What is the primary purpose of using a chromatograph in condensate analysis?

What is the primary purpose of using a chromatograph in condensate analysis?

Why are corrosion coupons typically made of a metal composition similar to that of the piping system?

Why are corrosion coupons typically made of a metal composition similar to that of the piping system?

What is the primary purpose of monitoring the corrosion byproducts of copper and iron?

What is the primary purpose of monitoring the corrosion byproducts of copper and iron?

Flashcards are hidden until you start studying

Study Notes

Primary Tests for Condensate

- pH readings are conducted to measure the acidity or basicity of the condensate

- Hardness tests are performed to determine the level of minerals in the condensate

- Conductivity measurements are used to determine the purity of the condensate

- Corrosion byproduct monitoring involves testing for iron oxides, copper oxides, and other corrosion products

Corrosion Byproduct Monitoring

- A commercially available iron analysis kit can be used to detect iron oxides

- Wet chemistry tests measure the amount of dissolved iron in a sample, with readings below 0.5 ppm considered acceptable

- Similar tests are available for copper analysis

Direct Amine Measurements

- A chromatograph is used to analyze a condensate sample and determine the molecules present

- Samples can be taken using a grab-sample bag and sent to a lab for analysis

- Some facilities use a continuous fluorometer to measure and monitor condensate amine concentration

Sample Collection and Preparation

- Samples should be taken at all critical points, including steam sections, condensate sections, and equipment prone to corrosion

- Samples must be cooled to less than 32°C (90°F) before collection

- The sample flow should be throttled at the outlet of the sampling system, and stainless steel lines should be used

- An adequate flow of material (1.5 – 2.0 m/s) is necessary, and the sampling device should be purged

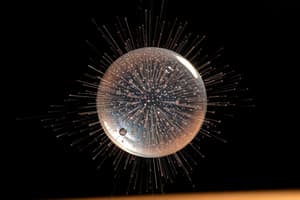

Corrosion Coupons

- Corrosion coupons are an inexpensive and simple way to evaluate corrosion rates

- They are only useful for estimating average corrosion rates, not providing instantaneous readings of system corrosiveness

- Coupons are metal strips of known mass, similar to the piping system's composition, and come in various shapes (strips, rods, discs)

- They are immersed in condensate for 1-3 months, then removed, cleaned, dried, and weighed to determine the corrosion rate

- The difference in weight over time gives an approximate corrosion rate, expressed in mils per year

- Coupons should be handled with care to prevent contamination, and Galvanic corrosion should be prevented using Teflon bolts

Primary Tests for Condensate

- pH readings are conducted to measure the acidity or basicity of the condensate

- Hardness tests are performed to determine the level of minerals in the condensate

- Conductivity measurements are used to determine the purity of the condensate

- Corrosion byproduct monitoring involves testing for iron oxides, copper oxides, and other corrosion products

Corrosion Byproduct Monitoring

- A commercially available iron analysis kit can be used to detect iron oxides

- Wet chemistry tests measure the amount of dissolved iron in a sample, with readings below 0.5 ppm considered acceptable

- Similar tests are available for copper analysis

Direct Amine Measurements

- A chromatograph is used to analyze a condensate sample and determine the molecules present

- Samples can be taken using a grab-sample bag and sent to a lab for analysis

- Some facilities use a continuous fluorometer to measure and monitor condensate amine concentration

Sample Collection and Preparation

- Samples should be taken at all critical points, including steam sections, condensate sections, and equipment prone to corrosion

- Samples must be cooled to less than 32°C (90°F) before collection

- The sample flow should be throttled at the outlet of the sampling system, and stainless steel lines should be used

- An adequate flow of material (1.5 – 2.0 m/s) is necessary, and the sampling device should be purged

Corrosion Coupons

- Corrosion coupons are an inexpensive and simple way to evaluate corrosion rates

- They are only useful for estimating average corrosion rates, not providing instantaneous readings of system corrosiveness

- Coupons are metal strips of known mass, similar to the piping system's composition, and come in various shapes (strips, rods, discs)

- They are immersed in condensate for 1-3 months, then removed, cleaned, dried, and weighed to determine the corrosion rate

- The difference in weight over time gives an approximate corrosion rate, expressed in mils per year

- Coupons should be handled with care to prevent contamination, and Galvanic corrosion should be prevented using Teflon bolts

Primary Tests for Condensate

- pH readings are conducted to measure the acidity or basicity of the condensate

- Hardness tests are performed to determine the level of minerals in the condensate

- Conductivity measurements are used to determine the purity of the condensate

- Corrosion byproduct monitoring involves testing for iron oxides, copper oxides, and other corrosion products

Corrosion Byproduct Monitoring

- A commercially available iron analysis kit can be used to detect iron oxides

- Wet chemistry tests measure the amount of dissolved iron in a sample, with readings below 0.5 ppm considered acceptable

- Similar tests are available for copper analysis

Direct Amine Measurements

- A chromatograph is used to analyze a condensate sample and determine the molecules present

- Samples can be taken using a grab-sample bag and sent to a lab for analysis

- Some facilities use a continuous fluorometer to measure and monitor condensate amine concentration

Sample Collection and Preparation

- Samples should be taken at all critical points, including steam sections, condensate sections, and equipment prone to corrosion

- Samples must be cooled to less than 32°C (90°F) before collection

- The sample flow should be throttled at the outlet of the sampling system, and stainless steel lines should be used

- An adequate flow of material (1.5 – 2.0 m/s) is necessary, and the sampling device should be purged

Corrosion Coupons

- Corrosion coupons are an inexpensive and simple way to evaluate corrosion rates

- They are only useful for estimating average corrosion rates, not providing instantaneous readings of system corrosiveness

- Coupons are metal strips of known mass, similar to the piping system's composition, and come in various shapes (strips, rods, discs)

- They are immersed in condensate for 1-3 months, then removed, cleaned, dried, and weighed to determine the corrosion rate

- The difference in weight over time gives an approximate corrosion rate, expressed in mils per year

- Coupons should be handled with care to prevent contamination, and Galvanic corrosion should be prevented using Teflon bolts

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.