Podcast

Questions and Answers

Which type of bond is characterized by alternating courses of headers and stretchers?

Which type of bond is characterized by alternating courses of headers and stretchers?

- Stack bond

- Common bond

- English bond

- Flemish bond (correct)

What is the primary benefit of using fly ash bricks in construction?

What is the primary benefit of using fly ash bricks in construction?

- Reduced cost of production (correct)

- Lower thermal conductivity

- Increased water absorption

- Higher weight

What is the main purpose of formwork in masonry construction?

What is the main purpose of formwork in masonry construction?

- To shape and support concrete until it sets (correct)

- To increase structural weight

- To provide insulation

- To enhance aesthetic appeal

Which type of formwork is typically made of plywood and is more versatile for complex shapes?

Which type of formwork is typically made of plywood and is more versatile for complex shapes?

Where should earthquake-resistant bands be located in masonry structures?

Where should earthquake-resistant bands be located in masonry structures?

Study Notes

Classification of Bricks

- Bricks are classified based on their manufacturing process, material used, and intended purpose.

- Common classifications include clay bricks, fly ash bricks, concrete bricks, and AAC blocks.

Manufacturing of Bricks

- Clay bricks are manufactured through traditional methods involving molding, drying, and firing in kilns.

- Fly ash bricks utilize fly ash as a primary ingredient, offering a sustainable alternative to clay bricks.

- Concrete bricks incorporate cement, aggregates, and water, providing a durable and versatile construction material.

- AAC blocks (Autoclaved Aerated Concrete) are lightweight blocks manufactured using a mixture of cement, lime, gypsum, and aluminum powder.

Tests on Bricks

- Water Absorption Test: Determines the brick's ability to soak up water, influencing its durability and frost resistance.

- Compressive Strength Test: Measures the brick's load-bearing capacity, crucial for structural applications.

- Efflorescence Test: Evaluates the presence of salts that can appear on the surface of the brick, affecting its aesthetics and performance.

Properties of Burnt Bricks

- Durability: Burnt clay bricks offer high durability and resistance to weathering.

- Compressive Strength: Burnt clay bricks exhibit good compressive strength, making them suitable for load-bearing structures.

- Fire Resistance: Burnt clay bricks are fire-resistant, contributing to building safety.

Fly Ash Bricks

- Fly ash bricks are produced using fly ash, a byproduct of coal-fired power plants.

- Advantages: Improved sustainability and reduced environmental impact compared to traditional clay bricks.

Autoclaved Aerated Concrete (ALC) Blocks

- ALC blocks are lightweight and easy to handle, reducing labor costs and construction time.

- They offer good thermal insulation and sound absorption properties, enhancing building comfort.

- ALC blocks are suitable for non-load-bearing walls, partitions, and roofs.

Brick Masonry Construction

- Technical Terms: Stretcher, header, bond, mortar, course, etc.

- General Principles: Mortar application, bond selection, proper laying techniques, curing process.

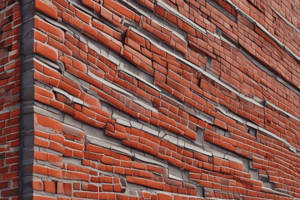

Common Bonds in Brick Masonry

- Stretcher Bond: Creates a simple, strong, and visually appealing pattern with all bricks laid horizontally.

- Header Bond: Features bricks laid perpendicular to the wall, creating a strong bond but potentially reducing aesthetic appeal.

- English Bond: Alternates courses of stretchers and headers, providing both visual appeal and structural stability.

- Flemish Bond: Uses a combination of stretchers and headers in each course, creating a visually complex yet strong pattern.

Formwork

- Types: Various types cater to different construction elements like beams, columns, slabs, and walls.

- Relative Merits and Demerits: Considerations include cost, ease of construction, material durability, and reusability.

- Removal Period: Removal times depend on concrete strength, weather conditions, and load-bearing requirements.

Earthquake Resistant Bands in Masonry

- Types: Reinforced concrete bands, steel bands, and masonry strengthening techniques.

- Location and Application: Strategically placed at critical levels of the structure (e.g., roof, floor) to increase resistance to seismic forces.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

This quiz covers the different classifications of bricks based on their manufacturing processes, materials, and intended uses. It also examines the manufacturing techniques for various types of bricks, such as clay, fly ash, concrete, and AAC blocks, along with essential tests that determine their quality and durability.