Podcast

Questions and Answers

What does CAD/CAM primarily involve?

What does CAD/CAM primarily involve?

- Computer-aided design and computer-aided manufacturing (correct)

- Only computer-aided manufacturing

- Only computer-aided design

- Manual design and manual manufacturing

What is the ultimate goal of CAD/CAM technology?

What is the ultimate goal of CAD/CAM technology?

- Reducing the quality of products

- Fully automated factory of the future (correct)

- Slowing down the design process

- Increasing the cost of manufacturing

What is a key aspect of product quality in industrial manufacturing?

What is a key aspect of product quality in industrial manufacturing?

- How quickly the product can be shipped

- The product characteristics meeting customer requirements (correct)

- The appearance of the product packaging

- The cost of the materials used

Which of the following is a category of how computers are used in industrial manufacturing?

Which of the following is a category of how computers are used in industrial manufacturing?

What is the primary purpose of monitoring in computer-interfaced manufacturing?

What is the primary purpose of monitoring in computer-interfaced manufacturing?

What is CAD primarily used for?

What is CAD primarily used for?

What does the CAD definition translator do?

What does the CAD definition translator do?

What is a primary function of CAM?

What is a primary function of CAM?

Where does the information used in the CAM process originate?

Where does the information used in the CAM process originate?

What is the initial stage of a product lifecycle?

What is the initial stage of a product lifecycle?

In a computer-aided manufacturing environment, what are the two main processes a product goes through?

In a computer-aided manufacturing environment, what are the two main processes a product goes through?

Which type of production involves manufacturing very small quantities, often one of a kind?

Which type of production involves manufacturing very small quantities, often one of a kind?

What characterizes 'fixed position layout' in plant layout design?

What characterizes 'fixed position layout' in plant layout design?

Which type of automation has a sequence of operations that is determined by the equipment configuration?

Which type of automation has a sequence of operations that is determined by the equipment configuration?

What is a main use of CAD/CAM in design evaluation?

What is a main use of CAD/CAM in design evaluation?

Flashcards

What is CAD/CAM?

What is CAD/CAM?

Computer-Aided Design and Computer-Aided Manufacturing. Technology applying digital computers to design and manufacturing functions.

What are Product Characteristics?

What are Product Characteristics?

Characteristics that describe a product's performance relative to customer needs or expectations.

What is Product Quality?

What is Product Quality?

Minimizing the loss to society during a product's entire existence.

What are Pre-Processing Applications?

What are Pre-Processing Applications?

Signup and view all the flashcards

What are direct interface applications?

What are direct interface applications?

Signup and view all the flashcards

What are support functions?

What are support functions?

Signup and view all the flashcards

What is CAD?

What is CAD?

Signup and view all the flashcards

What is CAM?

What is CAM?

Signup and view all the flashcards

What is Product Lifecycle?

What is Product Lifecycle?

Signup and view all the flashcards

What is Job Shop Production?

What is Job Shop Production?

Signup and view all the flashcards

What is Batch Production?

What is Batch Production?

Signup and view all the flashcards

What is Mass Production?

What is Mass Production?

Signup and view all the flashcards

What is Continuous Flow Production?

What is Continuous Flow Production?

Signup and view all the flashcards

What is Fixed Position Layout?

What is Fixed Position Layout?

Signup and view all the flashcards

What is Process Layout?

What is Process Layout?

Signup and view all the flashcards

Study Notes

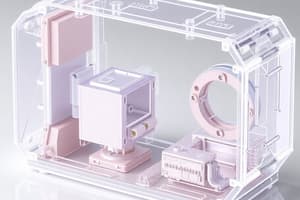

- Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) involves using digital computers to perform design and manufacturing functions

- CAD/CAM aims at fully automating the factory of the future by integrating design and manufacturing

Role of Computers in Manufacturing

- Products have characteristics that relate to customer requirements

- Quality is related to the lifecycle loss caused by a product to society

- Optimizing product design is important for production improvement, cost and achieving scheduled delivery times

- Computers should be used in industrial manufacturing

- Pre-processing support

- Monitoring and controlling the manufacturing process

- Post-processing support

CAD

- CAD is a design process using computer graphics and software packages

- CAD aids in analytical, development, costing, and ergonomic design issues

- The stages of a CAD process

- Geometric model definition

- Translator definition

- Interface algorithms

- Design and analysis algorithms

- Drafting and detailing

- Documentation

CAM

- CAM involves using computer systems to plan, manage, and control manufacturing

- CAM uses direct or indirect computer interface with production resources

- The CAD process generates the geometric model that forms the basis for CAM

- CAM activities use different types of data from the CAD process

- Interface algorithms

- NC programming

- Tool ordering

- Fixtures

- Computer-aided quality control software

Product Lifecycle

- The product cycle begins with a concept that is refined into a design engineering plan

- Conventional product lifecycle stages

- Design

- Part print preparation

- Tool ordering

- Machine ordering

- Material ordering

- Tool layout

- Production scheduling

- Manufacturing operations

- Standard work establishment

- Quality control

- Production

Computer-Aided Manufacturing Environment

- The product lifecycle starts with identifying a need based on market and customer demands

- From inception to completion, the product goes through the design and manufacturing processes

- Synthesis determines the product's philosophy, functionality, and uniqueness

- Analysis puts the conceptual design in the context of engineering sciences to evaluate performance

Manufacturing Industries

- Manufacturing industries can be classified according to:

- Quantity of product made

- Arrangement of physical facilities

- Manufacturing automation

Types of Production

- Production activities classified by product quantity

- Job shop production

- Batch production

- Mass production of discrete products

- Continuous flow process

Job Shop Production

- Low-volume production

- Small manufacturing lot sizes

- Equipment is flexible and general-purpose

- Examples

- Machine tools

- Space vehicles

- Aircraft

Batch Production

- Manufacturing of products in medium lots either once or at intervals

- Equipment is general purpose but designed for higher production rates

- Machine shops

- Casting foundries

- Plastic molding factories

- Press working shops

Mass Production

- High volume production

- Equipment is dedicated to a particular product

- High demand rates

- Examples

- Automobiles

- Household appliances

Continuous Flow Production

- Continuous bulk manufacturing of large amounts of a product

- Examples

- Chemical plants

- Oil refineries

Types of Plant Layout

- Plant layout is the arrangement of physical facilities

- Three layout types:

- Fixed position layout

- Process layout

- Product flow layout

Fixed Position Layout

- The product remains at one location due to size and weight

- Equipment and machinery are brought to the product

- Examples

- Aircraft assembly

- Shipbuilding

Process Layout

- Production machines are grouped by manufacturing process type

- Used in job shop and batch production

Product Flow Layout

- Plant facilities are arranged to produce one product or class of product in large volumes

Types of Automation

- Automation uses mechanical, electrical, electronic, and computer-based systems for production

- Three types

- Fixed

- Programmable

- Flexible

Fixed Automation

- Sequence of processing operations is fixed by the equipment configuration

- High initial investment in custom-engineered equipment

- High production rates

- Limited flexibility

- Examples

- Mechanized assembly lines

- Machining transfer lines

Programmable Automation

- Production machinery can change its operation sequence for different products

- Operation sequence is controlled by a program

- High initial investment in general-purpose equipment

- Low production rates

- Flexibility to accommodate product changes

- Suited for batch production

Flexible Automation

- Can manufacture a variety of products or parts

- Features:

- High initial investment for custom-engineered equipment

- Continuous production of variable mixtures

- Flexibility to accommodate changes

- Suited for mass production

Applications of CAD/CAM

- CAD/CAM is vital in qualitative manufacturing

- Geometric modeling

- Design engineering analysis

- Design evaluation and review

- Manufacturing database creation

- Computer-aided process planning (CAPP)

- Interactive graphics NC part programming

- Refined production planning

- Material requirements planning (MRP)

- Shop floor control

- Computer-aided inspection and quality control

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.