Podcast

Questions and Answers

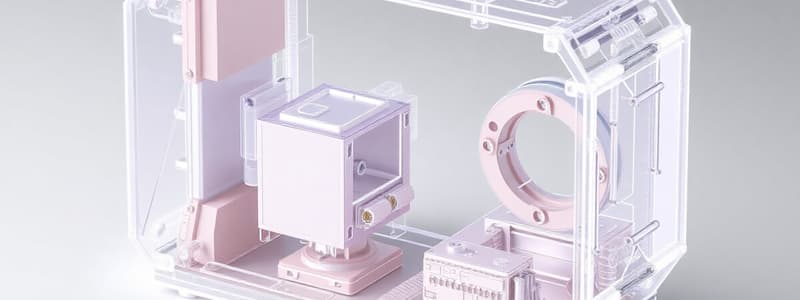

What does CAD/CAM mean?

What does CAD/CAM mean?

CAD/CAM means computer-aided design, and computer-aided manufacturing.

The role of computers in industrial manufacturing is broadly classified into the following groups:

The role of computers in industrial manufacturing is broadly classified into the following groups:

- Pre-processing support applications of the manufacturing system

- Monitoring and control of the manufacturing process

- Post-processing support applications of the manufacturing system

- All of the above (correct)

The use of computer software packages to aid in the analytical, development, costing and ergonomic problems associated with product design is known as:

The use of computer software packages to aid in the analytical, development, costing and ergonomic problems associated with product design is known as:

- CAD (correct)

- CAPP

- FEM

- CAM

The final stage in the implementation of a CAD system is:

The final stage in the implementation of a CAD system is:

The use of computer systems to plan, manage and control the operations of a manufacturing plant through either direct or indirect computer interface with the production resources is known as:

The use of computer systems to plan, manage and control the operations of a manufacturing plant through either direct or indirect computer interface with the production resources is known as:

In the computer direct interface, the manufacturing process is controlled by the:

In the computer direct interface, the manufacturing process is controlled by the:

The end goal of the synthesis sub-process is:

The end goal of the synthesis sub-process is:

The different phases that a product undergoes from the conceptualisation of the product until the end-product reaches the customer is known as:

The different phases that a product undergoes from the conceptualisation of the product until the end-product reaches the customer is known as:

Job shop production involves:

Job shop production involves:

Aircrafts are manufactured by:

Aircrafts are manufactured by:

Ship building is done in:

Ship building is done in:

Fixed automation is characterised by:

Fixed automation is characterised by:

Programmable automation is suitable for:

Programmable automation is suitable for:

Flashcards

CAD/CAM

CAD/CAM

Computer-aided design and computer-aided manufacturing; technology using digital computers for design and manufacturing functions.

Product Characteristics

Product Characteristics

Performance measures relative to customer needs; examples include power loss, strength, or profile.

Pre-processing Support Applications

Pre-processing Support Applications

Support functions facilitating efficient and economical manufacturing.

Computer Interfacing

Computer Interfacing

Signup and view all the flashcards

Support Functions for Quality Products

Support Functions for Quality Products

Signup and view all the flashcards

CAD Definition

CAD Definition

Signup and view all the flashcards

CAM Definition

CAM Definition

Signup and view all the flashcards

Product Lifecycle

Product Lifecycle

Signup and view all the flashcards

Job Shop Production

Job Shop Production

Signup and view all the flashcards

Batch Production

Batch Production

Signup and view all the flashcards

Mass Production

Mass Production

Signup and view all the flashcards

Continuous Flow Production

Continuous Flow Production

Signup and view all the flashcards

Plant Layout

Plant Layout

Signup and view all the flashcards

Fixed Position Layout

Fixed Position Layout

Signup and view all the flashcards

Process Layout

Process Layout

Signup and view all the flashcards

Study Notes

- CAD/CAM means computer-aided design and computer-aided manufacturing.

- It involves using digital computers for certain functions in design and manufacturing.

- The ultimate goal is a fully automated factory.

- Computers in manufacturing are used for pre-processing support, monitoring/control, and post-processing support.

Pre-processing Support

- Involves functions like computer-aided design and drafting and finite element analysis.

- Indirectly aids manufacturing by providing part programming, process planning, and scheduling.

- Relies on human input and interpretation of computer output.

Monitoring and Control

- Computers are directly interfaced with manufacturing processes.

- Monitoring involves observing the process and collecting data, controlled by an operator.

- Controlling involves monitoring and controlling the process based on observations using control algorithms.

Post-processing Support

- Focuses on delivering a quality product to customers using functions like computer-aided assembly and inspection.

CAD Definition

- CAD is a design process using computer graphics and software for analysis, development, costing, and ergonomics.

- After a concept is developed, a geometric model is started, dependent on the type of analysis needed.

- A definition translator within the CAD system converts designer input into the proper database format.

- Interface algorithms are used to extract data for engineering analysis.

- After finalizing the geometric model, drafting and detailing of the model start, followed by documentation and final drawings.

CAM Definition

- CAM uses computer systems to plan, manage, and control manufacturing plant operations through direct or indirect computer interface.

- The geometric model from CAD is the foundation for CAM.

- Interface algorithms extract information from the CAD database, and process planning leads to NC programs.

- After parts are manufactured, computer-aided quality control inspects them and robots assemble parts.

Product Lifecycle

- Begins with a concept and progresses through design engineering.

Traditional Manufacturing Environment

- After design, part prints are released for production.

- Production engineering assesses feasibility and creates the process plan for cost-effective production.

- Actions include making tools, acquiring equipment, procuring materials, and releasing instructions.

Computer-Aided Manufacturing Environment

- Begins with identifying a need.

- Synthesis determines the product's philosophy, functionality, and uniqueness, resulting in a conceptual design.

- The conceptual design is analyzed using engineering sciences for design modeling and simulation.

- Prototyping may occur to test the design, along with cost analyses.

- Design communication involves drawings, reports, and presentations.

Manufacturing Industries Classification by Quantity

- Job shop production involves low volume and high variety.

- Batch production involves manufacturing in medium lots, may be one-time or at regular intervals.

- Mass production involves very high volume and dedicated equipment.

- Continuous flow process involves continuous, dedicated bulk manufacturing.

Arrangement of Physical Facilities

- Fixed position layout involves the product remaining in one location.

- Process layout involves grouping machines by manufacturing process.

- Product flow layout is specially used for manufacturing one product in large volumes.

Types of Automation

- Automation uses mechanical, electrical, electronic, and computer-based systems for production.

- Automation systems include fixed, programmable, and flexible automation.

- Fixed automation has a fixed sequence, high initial investment, high production rates, and inflexibility.

- Programmable automation can change operations with a program, and has lower production rates versus fixed automation.

- Flexible automation is capable of making variety of products, requires high investment, and is suitable for mass production.

Applications of CAD/CAM

- Geometric modeling for complex product modeling and documentation.

- Design engineering analysis for stress, heat transfer, dynamics, and optimization.

- Design evaluation and review using automatic dimensioning and interference checking.

- Manufacturing database creation using documentation like dimensions and material specifications.

- Computer-aided process planning (CAPP) to improve production planning.

- Interactive graphics NC part programming to develop G- and M-codes.

- Finely tuned production planning.

- Material requirements planning (MRP).

- Shop floor control.

- Computer-aided inspection and quality control.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.