Podcast

Questions and Answers

What is the primary function of reinforcement bars (rebars) in concrete structures?

What is the primary function of reinforcement bars (rebars) in concrete structures?

- To increase the concrete's compressive strength.

- To provide thermal insulation to the concrete.

- To improve the aesthetic appearance of the concrete surface.

- To act as a tensioning device, resisting tensile forces. (correct)

Which of the following is a common material used to form rebars?

Which of the following is a common material used to form rebars?

- Stainless steel

- Carbon steel (correct)

- Galvanized iron

- Aluminum alloy

Which of the following describes a 'coursed rubble' type of masonry?

Which of the following describes a 'coursed rubble' type of masonry?

- Masonry constructed with large, irregular blocks fitted without mortar.

- Masonry with precisely squared stones and thin mortar joints.

- Masonry using rough, irregular stones without any discernible pattern.

- Masonry with approximately level beds at intervals with continuous level courses. (correct)

Which term describes the white, powdery deposit that can form on the surface of masonry or concrete?

Which term describes the white, powdery deposit that can form on the surface of masonry or concrete?

What is the main purpose of 'Type M' mortar in masonry construction?

What is the main purpose of 'Type M' mortar in masonry construction?

In brick masonry, what is a 'header'?

In brick masonry, what is a 'header'?

Which brick bond pattern consists of alternating headers and stretchers in each course?

Which brick bond pattern consists of alternating headers and stretchers in each course?

What is the purpose of a 'bond beam block' in masonry construction?

What is the purpose of a 'bond beam block' in masonry construction?

Which of the following describes a 'shoved joint' in masonry?

Which of the following describes a 'shoved joint' in masonry?

What is the primary component that defines 'bituminous materials'?

What is the primary component that defines 'bituminous materials'?

Which of the following is an example of a 'pitch', as it relates to bituminous materials?

Which of the following is an example of a 'pitch', as it relates to bituminous materials?

What characteristic defines 'thermoplastics'?

What characteristic defines 'thermoplastics'?

Which of these plastics is known for its high-impact strength and transparency, making it suitable for safety glazing?

Which of these plastics is known for its high-impact strength and transparency, making it suitable for safety glazing?

What is a key property of 'thermosetting plastics'?

What is a key property of 'thermosetting plastics'?

Which type of plastic is commonly used as the interlayer in safety glass?

Which type of plastic is commonly used as the interlayer in safety glass?

What is ‘Cohesiveness’ in the context of adhesives and sealants?

What is ‘Cohesiveness’ in the context of adhesives and sealants?

Which of the following is the correct way to describe ‘Adhesiveness’?

Which of the following is the correct way to describe ‘Adhesiveness’?

How does conduction transfer heat through a material?

How does conduction transfer heat through a material?

Which type of thermal insulation is characterized by relatively stiff and inelastic units?

Which type of thermal insulation is characterized by relatively stiff and inelastic units?

What is the primary way that reflective insulation works to reduce heat transfer?

What is the primary way that reflective insulation works to reduce heat transfer?

What is the purpose of 'soil poisoning' as a method of building protection?

What is the purpose of 'soil poisoning' as a method of building protection?

What is the function of a wood preservative?

What is the function of a wood preservative?

Compared to other surface treatments, what does “ratproofing” protect against?

Compared to other surface treatments, what does “ratproofing” protect against?

What distinguishes ‘Vapor Barriers’ from other coatings?

What distinguishes ‘Vapor Barriers’ from other coatings?

What is the primary function of the vehicle in paint?

What is the primary function of the vehicle in paint?

Which component of paint is the nonvolatile part of the vehicle that binds pigment particles into a cohesive film?

Which component of paint is the nonvolatile part of the vehicle that binds pigment particles into a cohesive film?

What is the typical function of 'thinners' in the context of paints?

What is the typical function of 'thinners' in the context of paints?

What is the main difference between varnishes and enamels?

What is the main difference between varnishes and enamels?

In the context of coatings, what is the primary function of sealers?

In the context of coatings, what is the primary function of sealers?

Which of the following is classified as 'rough hardware'?

Which of the following is classified as 'rough hardware'?

What distinguishes "finishing hardware" from "rough hardware" in building construction?

What distinguishes "finishing hardware" from "rough hardware" in building construction?

What is the purpose of ridges on rebars?

What is the purpose of ridges on rebars?

Which of the following is the type of tie which is especially favored for heavy work?

Which of the following is the type of tie which is especially favored for heavy work?

The hollow load-bearing concrete block has dimensions of?

The hollow load-bearing concrete block has dimensions of?

Hollow load-bearing concrete blocks typically weigh approximately?

Hollow load-bearing concrete blocks typically weigh approximately?

Which the definition for ‘kiln’?

Which the definition for ‘kiln’?

What does the abbreviation 'ABS' mean in plastics?

What does the abbreviation 'ABS' mean in plastics?

Tar results from?

Tar results from?

Which of the following best describes type N mortar?

Which of the following best describes type N mortar?

Which of these options best describes what “Flare header” refers to?

Which of these options best describes what “Flare header” refers to?

Flashcards

Building Materials

Building Materials

Items commonly used for building construction to create a cohesive structure.

Rebar

Rebar

Steel bar used as a tensioning device in reinforced concrete and masonry.

Snap Tie or Simple Tie

Snap Tie or Simple Tie

A tie where the wire is wrapped once around the crossing bars diagonally and twisted tight.

Wall Tie

Wall Tie

Signup and view all the flashcards

Double-Strand Single Tie

Double-Strand Single Tie

Signup and view all the flashcards

Saddle Tie

Saddle Tie

Signup and view all the flashcards

Saddle Tie With Twist

Saddle Tie With Twist

Signup and view all the flashcards

Cross Tie or Figure-Eight Tie

Cross Tie or Figure-Eight Tie

Signup and view all the flashcards

Masonry

Masonry

Signup and view all the flashcards

Hollow Load-Bearing Concrete Block

Hollow Load-Bearing Concrete Block

Signup and view all the flashcards

Solid Load-Bearing Block

Solid Load-Bearing Block

Signup and view all the flashcards

Hollow; Non-Load Bearing Concrete Block

Hollow; Non-Load Bearing Concrete Block

Signup and view all the flashcards

Concrete Masonry Unit

Concrete Masonry Unit

Signup and view all the flashcards

Stretcher Block

Stretcher Block

Signup and view all the flashcards

Partition Block

Partition Block

Signup and view all the flashcards

Bullnose Block

Bullnose Block

Signup and view all the flashcards

Corner Block

Corner Block

Signup and view all the flashcards

Return-Corner Block

Return-Corner Block

Signup and view all the flashcards

Double-Corner Block

Double-Corner Block

Signup and view all the flashcards

Pilaster Block

Pilaster Block

Signup and view all the flashcards

Coping Block

Coping Block

Signup and view all the flashcards

Sash Block

Sash Block

Signup and view all the flashcards

Concrete Block

Concrete Block

Signup and view all the flashcards

Face shell

Face shell

Signup and view all the flashcards

Web

Web

Signup and view all the flashcards

Core

Core

Signup and view all the flashcards

Open-End Block

Open-End Block

Signup and view all the flashcards

Lintel Block

Lintel Block

Signup and view all the flashcards

Header Block

Header Block

Signup and view all the flashcards

Sound-Absorbing Masonry Unit

Sound-Absorbing Masonry Unit

Signup and view all the flashcards

Slump Block

Slump Block

Signup and view all the flashcards

Split-Face Block

Split-Face Block

Signup and view all the flashcards

Faced Block

Faced Block

Signup and view all the flashcards

Sill block

Sill block

Signup and view all the flashcards

Cap Block

Cap Block

Signup and view all the flashcards

Bond-Beam Block

Bond-Beam Block

Signup and view all the flashcards

Bond Beam

Bond Beam

Signup and view all the flashcards

Bitumen

Bitumen

Signup and view all the flashcards

Tar

Tar

Signup and view all the flashcards

Pitch

Pitch

Signup and view all the flashcards

Study Notes

Building Materials Overview

- Building materials are commonly used to construct buildings and create cohesive, complete structures.

Contents

- Reinforcement Bars

- Masonry

- Bituminous Materials

- Plastics

- Adhesives And Sealants

- Building Protection

- Paints And Protective Coatings

- Hardwares

Rebars (Reinforcing Bars)

- Rebars are common steel bars also known as reinforcing steel or deformed bars.

- They are used as tensioning devices in reinforced concrete and masonry structures, holding the concrete in compression.

- Rebars are usually made of carbon steel with ridges to improve mechanical anchoring within the concrete.

- Rebars are used in concrete and masonry works.

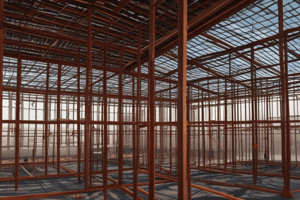

Rebar diagram

- H indicates point of origin, the letter or symbol of the producing mill

- Size Designation: Common sizes are 3, 4, 5, 6, 7, 8, 9, 10, 11, 14, and 18.

- S denotes the type of steel, such as Carbon-Steel (A615/A615M), Low-Alloy Steel (A706/A706M) or Stainless-Steel (A955/A955M)

- 60 is the Minimum Yield Designation (Grade Mark or Grade Line)

Tying Reinforcing Steel

- Snap Tie or Simple Tie: Wire wraps once diagonally around two crossing bars, twisted with sidecutters for tightness.

- Wall Tie: Wire goes 1 1/2 times around the vertical bar, then diagonally around the intersection, twisting ends tightly, and excess wire removed.

- Double-Strand Single Tie: A variation of simple tie, favored for heavy work.

- Saddle Tie: Wires pass halfway around one bar, brought squarely or diagonally around the crossing bar, twisted together, and cut off.

- Saddle Tie with Twist: Wire goes completely around one bar, across to the other, brought together and twisted.

- Cross Tie or Figure-Eight Tie: This type of tie causes little to no twist in the bars.

Masonry Overview

- Masonry involves building with natural or manufactured units like stone, brick, or concrete block.

- Mortar is commonly used as a bonding agent.

Concrete Blocks

- Hollow Load-Bearing Concrete Block: An 8" x 8" x 16" block weighs 40-50 lb with heavyweight aggregate and 25-35 lb with lightweight aggregate.

- Solid Load-Bearing Block: Has a core area of no more than 25% of the gross cross-sectional area.

- Hollow; Non-Load Bearing Concrete Block: The core area exceeds 25% of the cross-sectional area.

- Concrete Building Tile, Concrete Brick Common Sizes:

- 4" x 8" x 16" for non-load bearing partitions

- 6" x 8" x 16" for load-bearing walls

Concrete Block/Masonry Terminology

- Concrete Masonry Unit: A precast unit of portland cement, fine aggregate, and water, molded into various shapes.

- Stretcher Block: A concrete masonry unit having dimensions of 8 x 8 x 16 in (203 x 203 x 406 mm).

- Partition Block: A concrete masonry unit used in non-load-bearing walls, usually around 4-6 in (102 or 152 mm) thick.

- Bullnose Block: Unit with one or more rounded exterior corners.

- Corner Block: Unit with a solid end face, used at wall ends or corners.

- Return-Corner Block: Unit used at the corners of 6-12 in (152-305 mm) walls to maintain horizontal coursing.

- Double-Corner Block: Unit having solid faces at both ends, used in constructing a masonry pier.

- Pilaster Block: Units used in constructing a plain or reinforced masonry pilaster.

- Coping Block: A solid unit used as the top or finishing course of a masonry wall.

- Sash Block: A unit with an end slot or rabbet to receive the jamb of a door or window frame; also called jamb block.

- Concrete Block: A hollow or solid concrete masonry unit, often incorrectly called cement block.

- Face Shell: One of the two sidewalls of a hollow concrete masonry unit.

- Web: Cross walls connecting the face shells of a hollow masonry unit.

- Core: The molded open space in a concrete masonry unit; also called a cell.

- Open-End Block: Unit with one end open for vertical steel reinforcement to be embedded in grout.

- Lintel Block: Unit used for lintels/bond beams, having a U-shape for reinforcing steel embedment.

Other Concrete Block/Masonry Terminology

- Header Block: Unit with a portion of one face shell removed for headers in a bonded wall.

- Sound-Absorbing Masonry Unit: Unit with a solid top/slotted face shell/fibrous filler for increased sound absorption.

- Slump Block: Unit with irregular face texture due to settlement of wet mix during curing.

- Split-Face Block: Unit split lengthwise by a machine after curing.

- Faced Block: Unit having a special ceramic, glazed, or polished face.

- Tile Face Block

- Split Face Block

- Concrete Brick

- Column Blocks

- Solid Concrete Block

- Interlocking Block

- Screen Block

- Split Face Concrete Brick

- Paver

- Interlocking Paver

- Rabbet Receives jamb of a door or window frame; also called jamb block

- Sill block: Unit with a wash to shed rainwater.

- Wash: Surface inclined to shed rainwater; also called weathering.

- Cap block: Unit with a solid top for use as a bearing surface; also called solid-top block.

- Control-joint block: Units used in constructing a vertical joint.

- Bond-beam block: Unit used to construct a bond beam, with a depressed section for reinforcing steel.

- Bond beam: Course grouted and reinforced to serve as a beam or horizontal tie.

- Faced Block: Unit with a special ceramic, glazed, or polished face.

- Scored Block: Units with vertical grooves.

- Shadow Block: Units with a face shell with a pattern of beveled recesses.

- Screen Block: Units having a decorative pattern of transverse openings.

- Concrete Brick: A rectangular unit, usually not larger than 4 x 4 x 12 in (102 x 102 x 305 mm).

- Sand Lime Brick made with damp sand and slaked lime

Wall Surfaces

- Random Rubble: Rubble wall with discontinuous but approximately level beds or courses.

- Coursed Rubble: Rubble wall having approximate levels brought at intervals to continuous level courses.

- Squared Rubble: Rubble wall w/ squared stones of sizes coursed at every 3-4th stone.

- Cyclopean: Formed w/ large, irregular blocks of stones fitted closely without the use of mortar.

- Ashlar: Squared building stone finely dressed to permit very thin mortar joints.

- Random Ashlar: Ashlar masonry built in discontinuous courses.

- Coursed Ashlar: Ashlar masonry of stones having the same height, but each course varies in height.

- Broken Rangework: Ashlar masonry laid in horizontal courses of varying heights, broken at intervals.

Bricks

- Bricks are masonry units of clay, formed into a rectangular prism, hardened by drying or firing in a kiln. Terms:

- Common Brick: Made for general use, without special color or texture treatment; also called building brick.

- Facing Brick: Made of special clays for wall facing, often treated for desired color and surface; also called face brick.

- Brick Type: Indicates variation in size, color, chippage, and distortion.

- FBX: Suitable for use w/minimum variation in size, narrow color range, and high mechanical perfection.

- FBS: Suitable where a wider color range and size variation are permitted than for type FBX.

- FBA: Suitable where particular effects are desired from nonuniformity in size, color, and texture.

Brick Manufacturing & Designations

- Soft-Mud Process: Forming brick by molding wet clay (20-30% moisture).

- Sand-Struck Brick: Soft-mud process brick w/sand-lined mold, producing a matte texture.

- Water-Struck Brick: Soft-mud process brick w/water-lubricated mold for a smooth, dense surface.

- Stiff-Mud Process: Forming brick/structural tile by extruding stiff plastic clay (12-15% moisture), cutting with wires.

- Dry-Press Process: Forming brick by molding dry clay (5-7% moisture) under high pressure for sharp edges.

- Kiln: Oven for burning, baking, or drying, especially for pottery or bricks.

- Flashing: Firing brick units alternately with too much or too little air to vary their face color.

- Brick Grade: Indicates durability when exposed to weathering

Brick Designations & Components

- MW: Brick suitable for exposure to moderate weathering.

- SW: Suitable for exposure to sever weathering

- NW: Brick suitable for negligible weathering.

- Cull: A brick or timber rejected.

- Absorption: Weight of water absorbed by clay masonry when immersed, expressed as % of dry unit weight.

- Saturation Coefficient: Ratio of cold water to boiling water absorption, indicating freezing/thawing resistance.

- Suction: The water absorbed by a clay masonry unit when partially immersed for 1 minute.

- Efflorescence: A white, powdery deposit on surfaces caused by soluble salts.

- Firebrick: A brick made of fire clay and used for lining furnaces/fireplaces.

- Fire Clay: Refractory clay used in making firebricks.

- Refractory: Material retaining physical shape chemical identity when subjected to high temperatures.

- Clinker: Dense, hard-burned brick, especially for paving.

Brick Terminology

- Nominal dimension: Dimension larger than the actual dimension to account for mortar joint thickness.

- Modular brick: 4 x 2 2/3 x 8 in (102 x 68 x 203 mm)

- Norman brick: 4 x 2 2/3 x 12 in (102 x 68 x 305 mm).

- SCR brick: 6 x 2 2/3 x 12 in (102 x 68 x 305 mm).

- Engineered brick: 4 x 3 1/5 x 8 in (102 x 81 x 203 mm).

- Norwegian brick: 4 x 3 1/5 x 12 in (102 x 81 x 305 mm)

- Jumbo brick: oversized bricks established by the manufacturer

- Roman brick: 4 x 2 x 12 in (102 x 51 x 305 mm)

- Economy brick: 4 x 4 x 8 in (102 x 102 x 203 mm)

Brick Elements, Patterns, and Bonds

- Soap: Brick/tile having normal face dimensions but 2 in (51 mm) thick.

- Bat: Brick cut transversely to leave one end whole.

- Gauge: Chipping stones/bricks to a size/shape

- Stretcher: Brick laid horizontally with longer edge exposed or parallel to the surface.

- Header: Brick laid horizontally with the shorter end exposed or parallel to the surface.

- Rowlock: Brick laid horizontally on longer edge with shorter end exposed; also, rollock.

- Soldier: Brick laid vertically with the longer face edge exposed.

More Brick Elements, Patterns, and Bonds

- Sailor: Brick laid vertically with the broad face exposed.

- Shiner: Brick laid horizontally on longer edge with broad face exposed; also, bull stretcher

- Brickwork: Brick construction, the art of bonding bricks effectively.

- Bond: Masonry unit arrangements, a regular interlocking pattern increases strength appearance.

- Running Bond: Brickwork/masonry composed of overlapping stretchers; also brick stretcher bond.

- Common bond: Bond having a course of headers between every five or six courses of stretchers; also American bond.

- Closer: A masonry unit formed/cut to finish a course or complete the bond; also enclosure

- Stretching Course: Continuous course layers in brickwork

- Heading Course: Continuous course of headers in brickwork

- Bond Course: A continuous course of headers or bond overlapping

Brick Bonding Patterns

- English Bond: Alternating courses in which centered stetches line up vertically.

- Queen Closer: A brick of half width, for completing a course.

- English Cross Bond: Head joints in the stretching courses are offset by half length

- Flemish Bond: Alternating headers stretchers in each course, also centers above / below stretcher.

- King Closer: A three-quarter brick for finishing / spacing.

- Flare Header: A brick darker end exposed as a header in patterned brickwork.

- Flemish Diagonal Bond: Formed with courses as a diamond pattern.

- Garden-Wall Bond: A brickwork bond having sequence of 1 header / 3 stretchers in each course.

Masonry Terminology

- Masonry: Usually Building with structural products

- Term:

- Field: Expanse between openings/corners

Mortar and Joints

- Head Joint: The vertical joint between two masonry units

- Shoved Joint: Applying mortar along the joining

- Collar Joint: Joining between two wythes. vertical joint

- Bed Join: Horizontal joint

- Mortar: a product

Mortar & Components cont.

- field is the expanse of a masonry wall between openings. A course is a continuous layers are the range

- corbel projecting of brick or stone

- point- finish of point & tuck pointing

- tooled joint. compressed, weather-resistant mortar.

- troweled joint- finished with a trowel,

- raked joint-removing the mortar and then hardening.

- Concave- curved & v-joint-angular weathered joint, upper edger joints ready for the face with the masonry.

- struck joints upper level & tuck & pointing, bastrad/full joint-flat joint

Mortar & Uses

- plastic mixture, cement based; masonry construction

- cement mortar- portland cement, sand & water

- cememt-lime- a cement mix & is easy to use =masonry cement, propritery portland

- epoxy mortar-epoxy resin.

- nonstaining- low tree alkahi, migrations of soluble materials

Mortar Types

- Medium-high- or High Strength- M,S,N,O and K

- lime-heat of calcium carbonates. calcium oxide, hydrated lime-powder use for mortar

- green-not fully set,

- letmixs-short mix

- plasticer mixer concrete,

Masonry Composition

- hollow unit- set, bonded by masonry

- joint reinforced unit

- reinforced hollow- each cell grouted in

- any steel reinforced cracking.

Bitumen

- A generic name applied to a semisolid mixture of complex hydrocarbons, derived from coal or petroleum, as a coal-tar pitch or asphalt.

Bitumen Types

- Tar: Resulting condensate from destructive distillation of materials such as wood coal, shale, peat, or bone.

- Pitch: Solid or semi-solid residue from partial evaporation or fractional distillation of tar.

- Coal-Tar Pitch: Most common material.

- Asphalts: Dark brown or black solids or semi-solids in their natural state or produced by refining petroleum.

- Liquid Paving Asphalts: Liquid asphalts used for cutback paving (liquid asphalts used for paving are cutbacks).

- Asphalt Paving Cements: Binders for more expensive asphalt pavements.

Plastics General

- Are synthetic materials made from common substances like coal, salt, and oil.

- Relatively simple chemicals (monomers) react to produce chainlike molecules (polymers).

- Are synthetic/natural organic materials that can be molded, extruded, or drawn into objects, films, or filaments.

- Plastic Laminates: Three/more layers laminated w/ plastic adhesive under pressure.

Plastic General Classification

- Thermoplastics: Soften when heated and harden when cooled, regardless of the number of repetitions

- Thermosetting Plastics: Set into a permanent shape when heat/pressure are applied during forming.

Thermoplastics

- Polycarbonate: Tough used for safety lightning

- Polyethylene: Flexible and for packaging

- Polypropylene: It is resisting heat and chemicals

- Polystyrene: Stable

- Acrylonitrile-butadine-styrene: Used to rigid heat

- vinyl- poly vinyl reason

More Thermoplastic Info

- Polyvinyl Resin: Class resin with formula. also resin

- Polyvinyl Chloride: Water insulation

- Polyvinyl butyral: Thermos interlayer safety of class

- Nylon thermoplastic: Extreme, being able to get it

Thermosetting Plastics

- Polyurethane: Elastic and flexible and foams for sealants.

- Polyester: Group reisins.

- Fiber Glass plastics: Polyesters trannslucent

- Epoxy Resin tough structure

- Melamine Resin surface coaters, molded products

More Thermosetting Info

- Phenolic Resin resistance used to for products

- Bakelite : Trademark for resin. Invented by Dr leo

- Urea For resin,

- Melamine & Hard and Stable

Adhesives and Sealants

- Are synthetic materials from substances like coal, salt, oil, natural gas, cotton, wood, and water.

- Simple chemicals monomers

- Cohesiveness the particles, clinging together

- Adhesiveness-Material can be fixes and clean it

- Sealers-to seal material, of penetration of water or other escape

Heat Transfer

- Conduction: Heat moves through a material.

- Radiation: Heat radiates from a source. Heat rises and circulates.

- Convection: Warm and cold currents

- Important to try and prevent air from set up in the walls cealing.

Thermal Insulation

- Loose Fill: Made from fibrous materials such as mineral wool, wood fiber, cotton fiber or animal hair

- Blanket Insulation: Made from fibrous material to mat

- Batts: Covered with paper in short spances

- Structural insulation board (organic fiber: Wood, cane, straw, or cork)

More Thermal Insulation

- Reflective insulation: Aluminum of copper reflects heat

- Foamed inplace insulation (polyurethane )

- spayed on insulation materials used are foam abestos

- corrugareded Insulation, from paper into enclosed

Building Protection

- Waterproofing: Is a method of protecting surfaces against the destructiveeffects of water

- Damp proofin- is used from outside protect

- Soil poisoninf stops insects posts

- wood preservative is chemical- liquid applied protect agaiainst powder

- fire proofing applied and added srteng protection.

More Protection

- Rattling animals and wooden habitating

- Rooting matericals like steal iron

- Tgerpseal based water proof seal

- paper barrires effectivity layers

Paint and Protective Coatings

- Mixture which adjusted and diluted with correct type of addicties film

Paint

- Is mixture of particles to solid

- Pigment- liquid vehicle substance

- Vehicle liquid to surface

- Binder bond particals from dying

- Solent volatile easy dries

Painting Componants

- Thiners liquid diluted proper

- Mineral Spirits volotile used to thinners

- turpentice obtained distilling.

Paint Components

- Body: Finely ground material giving it powder.

- Vehicle: nonvolatile

- Pigment.

- Thinners- volatile solvant to allow better.

Varnish types

- Varnishesto proect surface

- Innames is an enamel pigmnt when this is added

- Eamel wood and steel Laquers to clear finshes by films

- latex.

- Shellac

Component Types

- Stands color surfacewithout concealing

- Filers material grain and protective

Hardware

- Metal products used in construction (e.g., bolts, hinges, locks).

Hardware Classification

- Finishing Hardware - Function and a finished appereance.

- Rough Hardware - Concealed

Rough Construction components

- Nails (common, annular, helical, doubled headed.

- Bolts.

- Washer Type

Fastning

- Fastening

- Nails slender piece hammered

- Cut nail tapering shape

- wired- ellipse shape

- Common : Fender , Diamionds

- Bond nail slim

- Casing Nail

- shak, set

More terms

- Screws and threads

- threads & tap, pull lots.

- Fast & striping

More

- Types: machine screw

More

Head types like bolts Flats ovals, rounds Drimver power. Staples

Metal Fittings

- Bolt Threaded metal head

- Carriage roundes

- Stover small, coarse

- “j”, “U”- eye bolt,

Metal Support

- Hanger Various brackets a. Beam

Finishes

- dowel circular prevents

- shear plate resistant

- Timber shear between members.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.