Podcast

Questions and Answers

EASY What are the factors that influence the frequency of waterside cleaning?

EASY What are the factors that influence the frequency of waterside cleaning?

- Operating schedule, operating conditions, feedwater quality, and water treatment control (correct)

- Waterside conditions and boiler design

- Operating conditions and water treatment control

- Feedwater quality and operating schedule

What is the primary purpose of using mechanical means to remove deposits from boiler surfaces?

What is the primary purpose of using mechanical means to remove deposits from boiler surfaces?

- To reduce corrosion

- To improve heat transfer

- To inspect the boiler surface

- To remove scale and improve efficiency (correct)

What type of tools are used to remove scale from watertube boilers?

What type of tools are used to remove scale from watertube boilers?

- Only power-driven tools

- Both hand tools and power-driven tools (correct)

- Only hand tools

- Neither hand tools nor power-driven tools

What is the purpose of directing a stream of water into the tube during mechanical cleaning?

What is the purpose of directing a stream of water into the tube during mechanical cleaning?

Why are mechanical cleaning methods not commonly used for larger watertube boilers?

Why are mechanical cleaning methods not commonly used for larger watertube boilers?

What is the primary method used to clean firetube boilers?

What is the primary method used to clean firetube boilers?

What is done to the tubes after mechanical cleaning is complete?

What is done to the tubes after mechanical cleaning is complete?

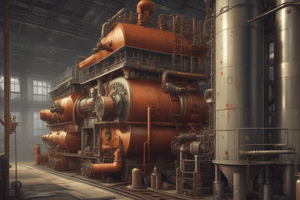

What is shown in Figures 2, 3, and 4?

What is shown in Figures 2, 3, and 4?

MEDIUM What is the primary challenge in mechanically cleaning larger watertube boilers?

MEDIUM What is the primary challenge in mechanically cleaning larger watertube boilers?

What is the purpose of using power tools in mechanical cleaning?

What is the purpose of using power tools in mechanical cleaning?

Why are mechanical cleaning methods not suitable for firetube boilers?

Why are mechanical cleaning methods not suitable for firetube boilers?

What is the result of using mechanical cleaning methods on larger watertube boilers?

What is the result of using mechanical cleaning methods on larger watertube boilers?

What is the function of hand tools in mechanical cleaning?

What is the function of hand tools in mechanical cleaning?

What is driven by small water-driven motors, compressed air driven motors, or electric motors in mechanical cleaning?

What is driven by small water-driven motors, compressed air driven motors, or electric motors in mechanical cleaning?

Why are mechanical cleaning methods used mostly on smaller watertube boilers?

Why are mechanical cleaning methods used mostly on smaller watertube boilers?

What is done to the tubes after mechanical cleaning is complete?

What is done to the tubes after mechanical cleaning is complete?

HARD What is a common limitation of using mechanical cleaning methods on larger watertube boilers?

HARD What is a common limitation of using mechanical cleaning methods on larger watertube boilers?

Why are mechanical cleaning methods often time-consuming and expensive?

Why are mechanical cleaning methods often time-consuming and expensive?

What is the primary advantage of using chemical cleaning methods for firetube boilers?

What is the primary advantage of using chemical cleaning methods for firetube boilers?

What is the purpose of flushing the tubes with high-pressure water after mechanical cleaning?

What is the purpose of flushing the tubes with high-pressure water after mechanical cleaning?

What type of motor is used to power mechanical cleaning tools in watertube boilers?

What type of motor is used to power mechanical cleaning tools in watertube boilers?

What is the main difference between hand tools and power tools used in mechanical cleaning?

What is the main difference between hand tools and power tools used in mechanical cleaning?

Why are rotary wire brushes used in mechanical cleaning of watertube boilers?

Why are rotary wire brushes used in mechanical cleaning of watertube boilers?

What is the primary purpose of using a stream of water during mechanical cleaning?

What is the primary purpose of using a stream of water during mechanical cleaning?

Flashcards are hidden until you start studying

Study Notes

Waterside Cleaning

- Frequency of waterside cleaning depends on operating schedule, operating conditions, feedwater quality, and water treatment control.

Mechanical Cleaning Methods

- Removal of deposits from boiler surfaces involves using hand tools or power-driven tools.

- Hand tools include scrapers, brooms, wire brushes, steam, water, or air lances.

- Power tools include those that cut or knock deposits from surfaces.

- In watertube boilers, scale forms on the inside surfaces of tubes, and can be removed with rotary wire brushes, cutters, and drill heads.

- Mechanical cleaning tools are powered by small water-driven motors, compressed air driven motors, or electric motors.

- Tools are manually guided through water tubes, and a stream of water is directed into the tube to provide cooling for the cutter heads and wash out scale.

- After mechanical cleaning, tubes are flushed with high-pressure water to remove loose scale from tube walls.

Limitations of Mechanical Cleaning

- Mechanical cleaning methods are mostly used on smaller watertube boilers.

- Larger watertube boilers are complex in design, making headers and other areas inaccessible, making mechanical cleaning impractical.

- Long, bent tubes are difficult or impossible to clean mechanically.

- Removing drum internals is time-consuming, making mechanical cleaning of large boilers expensive and not always effective.

Firetube Boilers

- There are no satisfactory methods to mechanically clean scale from firetube boilers.

- Firetube boilers are exclusively cleaned of excess scale buildup by chemical cleaning methods.

Waterside Cleaning

- Frequency of waterside cleaning depends on operating schedule, operating conditions, feedwater quality, and water treatment control.

Mechanical Cleaning Methods

- Removal of deposits from boiler surfaces involves using hand tools or power-driven tools.

- Hand tools include scrapers, brooms, wire brushes, steam, water, or air lances.

- Power tools include those that cut or knock deposits from surfaces.

- In watertube boilers, scale forms on the inside surfaces of tubes, and can be removed with rotary wire brushes, cutters, and drill heads.

- Mechanical cleaning tools are powered by small water-driven motors, compressed air driven motors, or electric motors.

- Tools are manually guided through water tubes, and a stream of water is directed into the tube to provide cooling for the cutter heads and wash out scale.

- After mechanical cleaning, tubes are flushed with high-pressure water to remove loose scale from tube walls.

Limitations of Mechanical Cleaning

- Mechanical cleaning methods are mostly used on smaller watertube boilers.

- Larger watertube boilers are complex in design, making headers and other areas inaccessible, making mechanical cleaning impractical.

- Long, bent tubes are difficult or impossible to clean mechanically.

- Removing drum internals is time-consuming, making mechanical cleaning of large boilers expensive and not always effective.

Firetube Boilers

- There are no satisfactory methods to mechanically clean scale from firetube boilers.

- Firetube boilers are exclusively cleaned of excess scale buildup by chemical cleaning methods.

Waterside Cleaning

- Frequency of waterside cleaning depends on operating schedule, operating conditions, feedwater quality, and water treatment control.

Mechanical Cleaning Methods

- Removal of deposits from boiler surfaces involves using hand tools or power-driven tools.

- Hand tools include scrapers, brooms, wire brushes, steam, water, or air lances.

- Power tools include those that cut or knock deposits from surfaces.

- In watertube boilers, scale forms on the inside surfaces of tubes, and can be removed with rotary wire brushes, cutters, and drill heads.

- Mechanical cleaning tools are powered by small water-driven motors, compressed air driven motors, or electric motors.

- Tools are manually guided through water tubes, and a stream of water is directed into the tube to provide cooling for the cutter heads and wash out scale.

- After mechanical cleaning, tubes are flushed with high-pressure water to remove loose scale from tube walls.

Limitations of Mechanical Cleaning

- Mechanical cleaning methods are mostly used on smaller watertube boilers.

- Larger watertube boilers are complex in design, making headers and other areas inaccessible, making mechanical cleaning impractical.

- Long, bent tubes are difficult or impossible to clean mechanically.

- Removing drum internals is time-consuming, making mechanical cleaning of large boilers expensive and not always effective.

Firetube Boilers

- There are no satisfactory methods to mechanically clean scale from firetube boilers.

- Firetube boilers are exclusively cleaned of excess scale buildup by chemical cleaning methods.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.