Podcast

Questions and Answers

Why is keeping heat transfer surfaces clean important?

Why is keeping heat transfer surfaces clean important?

To ensure maximum boiler efficiency.

What are some common methods of heat exchanger cleaning?

What are some common methods of heat exchanger cleaning?

Acid washing, alkaline cleaning, and steam injection.

What is the importance of monitoring the water level in a boiler?

What is the importance of monitoring the water level in a boiler?

To prevent dry-out of the furnace tiles and excessive thermal shock on the tubes.

Why is it necessary to check the feed pump regularly?

Why is it necessary to check the feed pump regularly?

What should be verified in the sequencing logic of a boiler?

What should be verified in the sequencing logic of a boiler?

Why is proper ventilation important in a boiler room?

Why is proper ventilation important in a boiler room?

Why is monitoring exhaust gas temperatures important in boiler maintenance?

Why is monitoring exhaust gas temperatures important in boiler maintenance?

What are some common components checked during a boiler system inspection?

What are some common components checked during a boiler system inspection?

How can adjusting combustion settings improve boiler performance?

How can adjusting combustion settings improve boiler performance?

Why is it important to clean the heat transfer surfaces of a boiler?

Why is it important to clean the heat transfer surfaces of a boiler?

What is the significance of regular boiler maintenance practices?

What is the significance of regular boiler maintenance practices?

What might high exhaust gas temperatures indicate in a boiler?

What might high exhaust gas temperatures indicate in a boiler?

Flashcards are hidden until you start studying

Study Notes

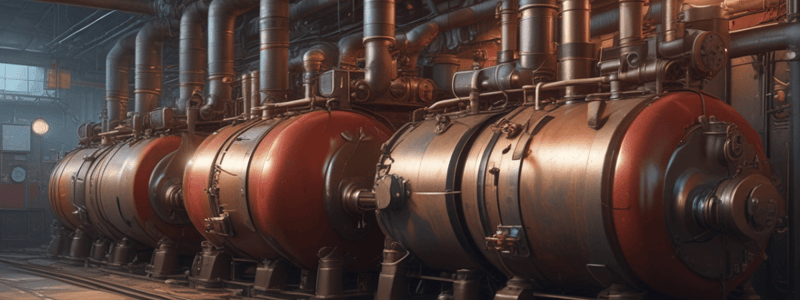

Boiler Maintenance

Boilers play a crucial role in providing heat and hot water to various industries and homes. Maintaining them properly is essential to ensure their longevity and efficiency. Here's what you need to know about boiler maintenance, including exhaust gas temperatures, boiler system inspections, combustion settings adjustments, heat transfer surface cleaning, and general maintenance practices.

Exhaust Gas Temperatures

Exhaust gas temperature (EGT) monitoring is important because it helps determine whether the fuel being burned efficiently or not. High EGTs can indicate potential issues within the boiler or with the fuel itself. As part of regular maintenance, these temperatures should be checked regularly and recorded over time.

Boiler System Inspection

Regular boiler system inspections help identify any signs of wear and tear or damage that could lead to leaks or failures. These inspections typically involve checking the pressure vessel, water level indicators, safety valves, burners, fans, and feedwater pumps. In addition, the inspector will look for evidence of corrosion, scaling, and leakage.

Combustion Settings Adjustments

Adjusting the combustion settings can help improve boiler performance by optimizing the ratio of air and fuel. This process involves changing the amount of oxygen supplied to the firebox, which affects the combustion efficiency. While this task is often performed during routine maintenance checks, less experienced personnel may prefer assistance from more experienced workers or consultants.

Heat Transfer Surfaces Cleaning

Keeping heat transfer surfaces clean is vital for ensuring maximum boiler efficiency. Dirt buildup can reduce heat transfer rates, leading to increased energy consumption. Regular cleaning schedules should be established, depending on factors such as local conditions, type of fuel used, and frequency of operation. Common methods of heat exchanger cleaning include acid washing, alkaline cleaning, and steam injection.

General Boiler Maintenance Practices

Apart from these specific tasks, there are several other maintenance practices that are crucial for maintaining a well-functioning boiler. These include:

- Monitoring the water level: Ensure the water level remains sufficient to prevent dry-out of the furnace tiles and excessive thermal shock on the tubes.

- Checking the feed pump: Ensure the feed pump is working correctly and there are no leaks. If needed, replace seals or gaskets.

- Inspecting the purges: Check if the purge system is functioning correctly and effectively removing flue gas contaminants.

- Monitoring the sequencing logic: Verify the sequencing logic is programmed correctly to operate the burner management control signal.

- Ensuring proper ventilation: Make sure the boiler room has adequate cross circulation ventilation to maintain comfortable working conditions.

By following these guidelines, boiler owners can extend the life of their equipment, avoid costly repairs, and enjoy reliable heating and hot water supply.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.