Podcast

Questions and Answers

The outlet of a safety relief valve can be pointed upwards when installed in a horizontal position.

The outlet of a safety relief valve can be pointed upwards when installed in a horizontal position.

False (B)

Fittings used to mount a safety relief valve can be smaller than the valve's inlet size.

Fittings used to mount a safety relief valve can be smaller than the valve's inlet size.

False (B)

A temperature relief device with a fusible element can reseat once the temperature returns to a safe level.

A temperature relief device with a fusible element can reseat once the temperature returns to a safe level.

False (B)

A combination temperature and pressure relief valve provides protection only against over-pressurization.

A combination temperature and pressure relief valve provides protection only against over-pressurization.

An annual try lever test is not recommended for T&P valves.

An annual try lever test is not recommended for T&P valves.

Flashcards are hidden until you start studying

Study Notes

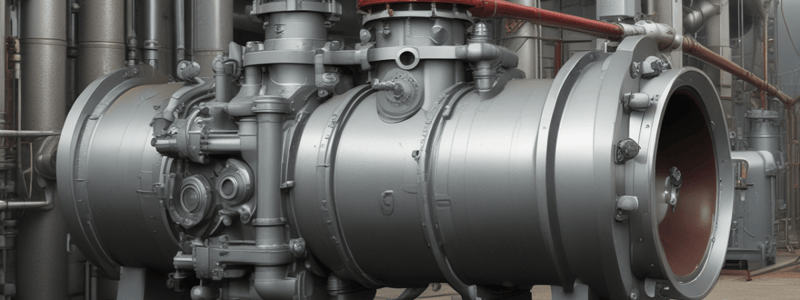

Safety Relief Valves in Commercial and Industrial Potable Water Heaters

- Safety relief valves are installed on commercial and industrial potable water heaters and hot water storage tanks, designed according to ASME BPVC IV, Part HLW.

- These heaters and tanks operate at pressures not exceeding 1100 kPa and temperatures not exceeding 99°C.

- Safety relief valves protect against explosion dangers associated with super-saturated hot water.

Temperature and Pressure Safety Relief Valves

- Most potable water heaters and hot water storage tanks use temperature and pressure safety relief valves.

- These valves protect against both over-pressurization and high water temperatures.

- ASME BPVC Section IV, Part HLW-800 refers to safety relief valve requirements for industrial and commercial potable water heaters.

Installation Requirements

- Safety relief valves must be installed not lower than 100 mm from the top of the shell.

- Valves must be directly connected to the water heater or a fitting connected to the water heater.

- Spindles must be upright and vertical, with no horizontal connecting pipe.

- No piping or fitting used to mount the safety relief valve can be smaller than the valve inlet.

- Safety relief valves shall not be connected to an internal pipe or a cold water feed line.

Combination Temperature and Pressure Relief Valves

- These valves provide protection for both over-pressurization and high water temperatures.

- The pressure element opens to relieve excess pressure, usually caused by thermal expansion.

- The temperature element opens when the water temperature rises to about 99°C.

- Unlike safety relief valves, T&P valves do not operate with a pop action when over-pressurization occurs.

Temperature-Sensitive Element

- The temperature-sensitive element consists of a wax-filled thermostatic sensor probe that extends into the water storage tank.

- When exposed to high temperature, the wax expands, lifts the valve disc off its seat, and discharges the overheated water.

- When the temperature returns to a safe level, the wax contracts, and allows the spring to reseat the valve.

Testing and Maintenance

- It is recommended that T&P valves receive annual try lever tests.

- Various types of temperature relief devices can be used, but they must always have additional pressure relief.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.