Podcast

Questions and Answers

What types of loads do ball bearings support?

What types of loads do ball bearings support?

- Radial loads only

- Thrust loads only

- Both radial and thrust loads (correct)

- None of the above

The main purpose of the crankshaft is to change ______ motion to ______ for propeller.

The main purpose of the crankshaft is to change ______ motion to ______ for propeller.

reciprocating, rotary

What are the four principal types of crankshafts?

What are the four principal types of crankshafts?

Single throw, double throw, four throw, six throw

The outer race of a ball bearing is made of case hardened steel.

The outer race of a ball bearing is made of case hardened steel.

What material is commonly used for the common style of plain bearings?

What material is commonly used for the common style of plain bearings?

What is a characteristic of the crankpin?

What is a characteristic of the crankpin?

Match the types of bearings with their characteristics:

Match the types of bearings with their characteristics:

Counterweights are used to reduce vibrations in a crankshaft.

Counterweights are used to reduce vibrations in a crankshaft.

What must be done during the overhaul of crankshafts regarding lubrication passages?

What must be done during the overhaul of crankshafts regarding lubrication passages?

What is the purpose of the transverse webs in the crankcase?

What is the purpose of the transverse webs in the crankcase?

Flashcards are hidden until you start studying

Study Notes

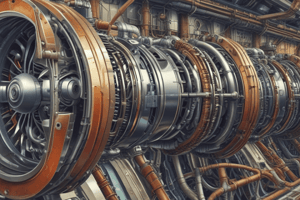

Bearings

- Bearings minimize friction and maximize durability, essential for smooth operation.

- Types include revolving (roller) and supporting (plain) bearings that stabilize components with tight tolerances.

- Thrust loads are managed by thrust bearings, while radial or combined loads utilize ball bearings.

Thrust and Radial Loads

- Plain bearings primarily handle radial loads; flanged designs can accommodate thrust loads.

- Common materials for plain bearings include silver, bronze, lead, and various alloys.

- Popular configuration: steel backing with a silver layer and lead surface or bronze backed with lead or Babbitt; Babbitt reduces friction more effectively than bronze.

Roller Bearings

- Designed to reduce friction for both radial and thrust loads.

- Straight roller bearings are suited for radial loads, while tapered roller bearings handle both thrust and radial.

- Composed of inner and outer races where rollers travel; components are made from case-hardened steel.

Ball Bearings

- Offer the least rolling friction; effective for all load types, particularly heavy thrust loads.

- Constructed with inner and outer races, polished steel balls, and a ball retainer.

- Heavier races advocate for proper installation due to directional thrust requirements; prelubricated versions need careful handling to protect seals.

Crankshaft

- Acts as the backbone in reciprocating engines, converting reciprocal motion from pistons into rotary motion for propellers.

- Typically forged and then machined from strong steel alloys such as SAE 4330.

- Main bearings must be rigidly supported in the crankcase, often utilizing transverse webs for structural integrity.

Types of Crankshafts

- Principle types: Single throw, Double throw, Four throw, Six throw.

- Higher-output engines necessitate enhanced balance and wear resistance.

Single-Throw Crankshaft

- Single rotation around 360 degrees; uses split master rods for two-piece designs.

- Features clamps for connection; can be configured as two-piece using spline systems for versatility.

Double Throw Crankshaft

- Features a 180-degree configuration, often in twin-row formats; designed for one throw per engine bank.

- Can be constructed as one or three pieces using ball or roller bearings.

Four-Throw Crankshaft

- Utilized in inline and opposed 4-cylinder engines and V8 configurations.

- Contains variations in throw positions, maintaining multiple main journals for stability.

Six-Throw Crankshaft

- Common in 6-cylinder in-line engines and V12 configurations.

- Typically crafted from 4340 forged steel, featuring hollow crank designs for weight reduction and enhanced balance.

Main Journal

- Also known as the main bearing journal, it carries load and maintains alignment, rotating within bearings.

- Surface is hardened through nitriding to a depth of 0.015-0.025 inches to reduce wear.

Crankpin and Crank Cheek

- Crankpin facilitates the connection between the connecting rod and the crankshaft, incorporating weight for balance.

- Drilled passages ensure proper lubrication and debris management.

Crankshaft Balance

- Balance is crucial to minimize excessive vibration, which leads to fatigue and rapid wear of metal structures.

- Checked during overhaul for run-out issues; unbalanced crankshafts can adversely affect engine performance.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.