Podcast

Questions and Answers

What is the primary purpose of the perforations in the inner liner of a typical combustor?

What is the primary purpose of the perforations in the inner liner of a typical combustor?

- To provide structural support for the combustor casing.

- To regulate the amount of fuel entering the combustion chamber.

- To allow for easier removal of the combustor for maintenance.

- To specifically affect flame propagation within the liner. (correct)

Why is a fuel drainage system an essential component of a gas turbine engine's combustion section?

Why is a fuel drainage system an essential component of a gas turbine engine's combustion section?

- To regulate fuel flow to the fuel nozzles, optimizing engine efficiency.

- To prevent over-pressurization of the fuel lines during engine start-up.

- To drain unburned fuel after engine shutdown, preventing fires and gum deposits. (correct)

- To ensure complete combustion of fuel during engine operation.

In a gas turbine engine combustor, what is the role of the primary air?

In a gas turbine engine combustor, what is the role of the primary air?

- To cool the combustor liner and prevent warping.

- To provide a high-velocity airflow that prevents flameout.

- To cool the turbine blades before exhaust.

- To mix with the fuel and sustain the combustion process. (correct)

Why is it important to reduce the axial velocity of airflow in the primary combustion zone?

Why is it important to reduce the axial velocity of airflow in the primary combustion zone?

What is the purpose of flame propagation tubes in a multiple-can combustion chamber?

What is the purpose of flame propagation tubes in a multiple-can combustion chamber?

What is a key advantage of an annular combustor compared to multiple-can combustors?

What is a key advantage of an annular combustor compared to multiple-can combustors?

What is a lean die-out flameout, and under what conditions is it most likely to occur?

What is a lean die-out flameout, and under what conditions is it most likely to occur?

In a turbine section, what is the primary function of the turbine nozzle (stator)?

In a turbine section, what is the primary function of the turbine nozzle (stator)?

Why is it essential for turbine nozzle vanes to be constructed to allow for thermal expansion?

Why is it essential for turbine nozzle vanes to be constructed to allow for thermal expansion?

What is the purpose of using multiple turbine stages in some gas turbine engines?

What is the purpose of using multiple turbine stages in some gas turbine engines?

Why are turbine blades designed to fit somewhat loosely into the turbine disk when the engine is cold?

Why are turbine blades designed to fit somewhat loosely into the turbine disk when the engine is cold?

How do reaction turbine blades produce a turning force?

How do reaction turbine blades produce a turning force?

What is the primary purpose of shrouds on turbine blades?

What is the primary purpose of shrouds on turbine blades?

What is Transpiration Cooling, and where is it typically employed?

What is Transpiration Cooling, and where is it typically employed?

What effect does the design of a turbojet engine exhaust section have on engine performance?

What effect does the design of a turbojet engine exhaust section have on engine performance?

What is the purpose of the diverging passage between the outer duct and inner cone in a typical exhaust cone assembly?

What is the purpose of the diverging passage between the outer duct and inner cone in a typical exhaust cone assembly?

What is the primary function of an afterburner in a gas turbine engine?

What is the primary function of an afterburner in a gas turbine engine?

Why are thrust reversers used on many turbine-powered aircraft?

Why are thrust reversers used on many turbine-powered aircraft?

What is the function of the accessory section, or accessory drive, on a gas turbine engine?

What is the function of the accessory section, or accessory drive, on a gas turbine engine?

Why are station numbers assigned to various points along a turbine engine's gas path?

Why are station numbers assigned to various points along a turbine engine's gas path?

Flashcards

Combustion Chamber (Combustor)

Combustion Chamber (Combustor)

A section in turbine engines where fuel and air mix and burn.

Fuel Injection System

Fuel Injection System

Meters fuel into combustors, ensuring thorough mixing with air for efficient burning.

Capacitor Discharge System

Capacitor Discharge System

Ignites the fuel-air mixture in gas turbine engines.

Fuel Drainage System

Fuel Drainage System

Signup and view all the flashcards

Primary Air

Primary Air

Signup and view all the flashcards

Flameout

Flameout

Signup and view all the flashcards

Flame Propagation Tubes

Flame Propagation Tubes

Signup and view all the flashcards

Turbine Nozzle (Stator)

Turbine Nozzle (Stator)

Signup and view all the flashcards

Turbine Disk

Turbine Disk

Signup and view all the flashcards

Turbine Blades

Turbine Blades

Signup and view all the flashcards

Fir Tree Slots

Fir Tree Slots

Signup and view all the flashcards

Impulse Blades

Impulse Blades

Signup and view all the flashcards

Reaction Blades

Reaction Blades

Signup and view all the flashcards

Convection / Film Cooling

Convection / Film Cooling

Signup and view all the flashcards

Transpiration Cooling

Transpiration Cooling

Signup and view all the flashcards

Exhaust Cone Assembly

Exhaust Cone Assembly

Signup and view all the flashcards

Tailpipe

Tailpipe

Signup and view all the flashcards

Exhaust Nozzle

Exhaust Nozzle

Signup and view all the flashcards

Afterburner

Afterburner

Signup and view all the flashcards

Thrust Reversers

Thrust Reversers

Signup and view all the flashcards

Study Notes

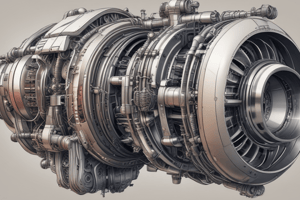

Combustion Section Overview

- It is located between the compressor diffuser and turbine section

- Includes combustion chambers, a fuel injection system, an ignition source, and a fuel drainage system

Combustion Chamber (Combustor)

- Where fuel and air mix and burn in a turbine engine

- It features an outer casing with a perforated inner liner

- Perforations size and shape affect flame propagation

Fuel Injection System

- Meters fuel through nozzles into combustors

- Nozzles are in the combustion chamber case or compressor outlet elbows

- Fuel is delivered as a finely atomized spray for thorough mixing with air

- Finer spray increases combustion speed and efficiency

Ignition Source

- A typical ignition source is a high-energy capacitor discharge system

- It includes an exciter unit, two high-tension cables, and two spark igniters

- The system produces 60 to 100 sparks per minute, creating a ball of fire at the igniter electrodes

- Some systems have sparks that shoot out several inches

- Use caution during maintenance tests to avoid lethal shock

Fuel Drainage System

- Drains unburned fuel after engine shutdown

- Reduces the risk of fire due to exceeding temperature limits

- Prevents gum deposits in fuel manifolds and combustion chambers

Combustion Chamber Efficiency Requirements

- Mixes fuel and air effectively

- Efficiently burns the mixture

- Cools combustion gases to a temperature the turbine blades can tolerate

- Distributes hot gases evenly to the turbine section

Airflow Division

- Airflow through a combustor is divided into primary and secondary paths for mixing, ignition, and cooling

- 25-35% of incoming air is primary air

- 65-75% of incoming air is secondary air

Primary (Combustion) Air

- Directed inside the liner in the front end of the combustor

- Passes through swirl vanes to create radial motion

- Axial velocity is reduced to about 5-6 feet per second

- Velocity reduction accommodates the slow flame propagation rate of kerosene-type fuels

- Excessively high airflow can cause a flameout

- A vortex is created for turbulence to properly mix fuel and air

- Combustion completes in the first third of a combustor

Secondary Airflow

- Flows at hundreds of feet per second around the combustor's periphery

- Forms a cooling air blanket on both liner sides

- Centers combustion flames to prevent liner contact

- Some is slowed and metered through liner perforations to ensure combustion of unburned fuel

- Secondary air mixes with burned gases and cool air to evenly distribute energy to the turbine nozzle

Combustion Chamber Types

- Multiple-can

- Annular (basket)

- Can-annular

- Functionally same, differing design and construction

Multiple-Can Type

- Consists of individual combustor cans acting as burner units

- Well-suited for centrifugal compressor engines due to even air distribution at the diffuser

- Each can has a perforated stainless steel liner inside the outer case

- The Inner liner is heat resistant and removable for inspection

- High curvature provides resistance to warpage

- Inefficient shape in terms of space and weight

Multiple-Can Interconnection

- Individual combustors connected by small flame propagation tubes

- Combustion starts in two cans with igniter plugs

- Flame travels through tubes to ignite fuel/air mixture in other cans

- Flame propagation tube has a small inner tube carrying flame

- The outer tube carries airflow between the cans, cooling and insulating

- A typical combustion section has 8 or 10 cans

- Cans are numbered clockwise facing the rear of the engine in American-built engines, with the number one can on top

- All combustor cans discharge exhaust gases into an open area at the turbine nozzle inlet

Annular Type

- Commonly used in small and large engines

- Most efficient in terms of thermal efficiency, weight, and physical size

- Consists of a housing and perforated inner liner (basket)

- Liner encircles the outside of the turbine shaft housing

- Shroud shaped to contain one or more concentric baskets

- An annular combustor with two baskets is a double-annular combustion chamber

- Normally, the ignition source consists of two spark igniters

- Airflow enters at front and discharges at rear similar to multiple-can design

- It must be removed as a single unit for repair where complete engine separation is usually required

Reverse-Flow Annular Combustors

- Airflow can reverse direction in some designs

- Functions like conventional flow types, but air flows around chamber and enters from rear

- Combustion gases flow opposite to normal airflow

- First used by Whittle in his early designs

Can-Annular Type

- Combines features of both multiple-can and annular combustors

- Invented by Pratt & Whitney

- A removable steel shroud that encircles the combustion section

- Multiple burner cans assembled radially around engine axis with bullet-shaped perforated liners

- Fuel nozzle cluster is attached to forward end of each burner can

- Pre-swirl vanes enhance the combustion process and slow air velocity

- Flame propagation tubes connect individual liners

- Two igniter plugs are used for initiating combustion

- An individual can and liner is removed and installed as one unit

Flameout

- Combustion flame can be extinguished by high airflow rates

- Excessively slow airflow rates can also contribute

- Although flameout is uncommon, combustion instability can still occur

- Turbulent weather, high altitude, slow acceleration, and high-speed maneuvers can induce a flameout

Types of Flameout

- Lean die-out: Usually occurs at high altitude with low engine speeds and low fuel pressure, forms a weak flame

- Rich blow-out: Occurs during rapid acceleration, overly-rich mixture drops fuel temperature

Turbine Section

- It extracts energy after the fuel/air mixture is burned

- Transforms kinetic energy in hot exhaust gases into mechanical energy to drive the compressor and accessories

- Absorbs approximately 60 to 80% of the total pressure energy

- It is located downstream of the combustion section

- Basic elements include a case, stator, shroud, and rotor

Turbine Stator

- Commonly referred to as the turbine nozzle, turbine guide vanes, or nozzle diaphragm

- Located directly aft of the combustion section and forward of the turbine wheel

- Exposed to the highest temperatures in a gas turbine engine

Function of Turbine Nozzle

- Collect high-energy airflow from combustors

- Direct flow to strike the turbine rotor at the appropriate angle

- Vanes are contoured and set at an angle

- Angle forms converging nozzles to convert pressure energy to velocity energy

- Stator vanes are set in the direction of turbine wheel rotation

Turbine Casing

- Encloses turbine rotor and stator assembly

- Provides direct or indirect support to the stator elements

- Typical case has flanges on both ends for attaching to combustion section and exhaust assembly

Shroud

- Turbine nozzle assembly comprised of inner and outer shroud that retains and surrounds the nozzle vanes

- Vanes are assembled between the outer and inner shrouds or rings

- Vane number varies

- Nozzle vanes constructed to allow for thermal expansion

- There would be distortion or warping if not

Thermal Expansion Solutions

- Vanes loosely assembled in inner and outer shrouds with contoured slots slightly larger than the vanes for loose fit

- Inner and outer shrouds are encased in inner and outer support ring for strength and rigidity

- Vanes rigidly welded or riveted into segmented shrouds

- The inner or outer shroud ring is cut into segments to allow for expansion

- Expansion closes gaps between shroud segments, preventing stress and warping

Turbine Rotor

- Rotating elements consist of a shaft and turbine rotor (wheel)

- Turbine wheel: Dynamically balanced unit with blades attached to a rotating disk

- Turbine disk: Anchoring component for turbine blades bolted or welded to main shaft

- Shaft rotates in bearings lubricated by oil to reduce vibration and misalignment

Turbine Blades

- Airfoil-shaped components designed to extract maximum energy from hot gases

- Forged or cast depending on alloy composition

- Primarily cast nickel-based alloys

- They must be finish-ground to desired shape after forging or casting

- The development of reinforced ceramic material holds promise

- Initial use is likely to be in small, high-speed turbines that operate at very high temperatures

Turbine Blade Fit and Attachment

- Blades fit loosely into turbine disk when cold, expand to fit tightly at operating temperatures

- Common attachment method: Fir tree slots cut into turbine disk rim and matching bases cast or machined into blade base

- Once installed, a turbine blade may be retained in its groove by peening, welding, rivets, or locktabs

- Peening is frequently in various ways

- Application requires a small notch to be ground in the edge of the blade being installed

- The blade is inserted into the disk metal, which "flowed" into the notch

- Use a small punch mark, making the tool similar to a center punch

Turbine Blade Classification

- Classified as impulse, reaction, or a combination of both

- that use impulse blades change the direction of airflow, causing no change in gas pressure or velocity

- Turbine wheel absorbs force to change the direction of airflow and converts it to rotary motion

- Reaction turbine blades produce a turning force based on aerodynamic action

- Ducts increase gas velocity and reduce pressure, similar to an airfoil creating lift

Impulse Turbine System

- Nozzle vanes form converging ducts

- Increases velocity of exhaust gases

- Blades extract energy by redirecting the flow of gas

Reaction Turbine

- Nozzle guide vanes direct exhaust gas flow to strike the blades at a positive angle of attack

- Convergent shape increases gas velocity and decreases resulting pressure to create lift that rotates the wheel

Impulse-Reaction Turbine blades

- Modern engines incorporate impulse-reaction blades to distribute workload evenly

- The Blade base is impulse shaped

- The blade tip is reaction shaped

- Design achieves uniform velocity and pressure drop

Shrouded Blades

- Shrouded blades are connected at their ends

- Blades can be open or shrouded

- Open-ended blades are used on high-speed turbines

- Shrouded blades are used on turbines with slower speeds

- Shrouds of blades contact each other, providing support and reducing vibration

- Prevent air from escaping over the blade tips, increasing efficiency

- Added weight makes shrouded blades more susceptible to blade growth

- A knife-edge seal is machined around the outside of the shroud

- Minimizes air losses at the blade tip

Turbine Cooling

- Common way to cool components is using engine bleed air

- Turbine disks absorb heat from hot gases near their rim and blades through conduction

- Cooling air is directed over each side of the disk to limit temperature variations

- Compressor bleed air is directed through hollow blades and out holes in the tip/edges

- Cooling is known as convection or film cooling

- Some vanes are constructed of porous, high-temperature material

- High-temperature material uses transpiration cooling

- Air is ducted into the vanes and exits through the porous material

- Engine designs use a combination of internal and surface cooling methods

- Turbine vane shrouds may also be perforated with cooling holes

Counter-Rotating Turbines

- Some smaller turboshaft engines feature counter-rotating turbine wheels

- Chosen for dampening gyroscopic effects and reducing engine vibration

Turbine Design: Temperature

- Temperature is the most limiting factor in running a gas turbine engine

- The higher the temperature of the incoming air, the more power/thrust an engine can produce

- Effective cooling systems are important as a result

- Cooling systems allow the turbine vane and blade components to operate between 600 to 800 degrees Fahrenheit above metal alloy temperature limits

Exhaust Section

- Design exerts tremendous influence on engine performance

- Shape and size of an exhaust section affect turbine inlet temperature

- Mass airflow through the engine and velocity/pressure of exhaust jet affect engine performance

- Determines amount of thrust developed

Exhaust Section Components

- Extends from the rear of turbine section to the exhaust gases

- The exhaust section has an exhaust cone, exhaust duct, and exhaust nozzle

Exhaust Cone

- Consists of an outer duct/shell, an inner/tail cone, radial hollow struts, and tie rods

Purpose of Exhaust Cone

- Channels and collects turbine discharge gases into a single jet

- Gas velocity decreases while pressure rises

- Supports the inner cone and straightens swirling exhaust gases

- Straighten gases from turbine

Tailpipe

- Extends from exhaust cone to the exhaust or jet nozzle

- Results in a penalty on engine's operating efficiency because of heat and duct friction losses, which reduces exhaust gas velocity and therefore thrust

- Used for engines installed within an aircraft's fuselage to protect the surrounding airframe

- Engines installed in a nacelle or pod, do not usually require one

Exhaust Nozzle

- Provides exhaust gases with a final velocity boost

- Mounts to rear of tailpipe for an existing tailpipe, to rear flange of exhaust duct with need for a tailpipe

Exhaust Nozzle Types

- Converging design: Nozzle diameter decreases from front to back, accelerates exhaust gases and increases engine thrust

- Converging-diverging design: Diameter decreases, then increases with supersonic speed

- Turbine exhaust gases accelerate to supersonic speed at narrowest duct part

- Gases are accelerated further in diverging portion

Fan or Bypass Engines

- High-temperature gases discharged by turbine, cool airmass moved rearward by fan section

- Low bypass: hot cool air combined in a mixer unit

- High bypass: Flows discharge separately through two sets of coaxially exhausts

- Some high bypass have a common part

Nozzle Opening

- Fixed or variable area

- Engines that utilize an afterburner need a variable geometry

- Operated with pneumatic, hydraulic, or electric controls

Afterburners

- Used to accelerate exhaust gases, which in turn, increases thrust

- Installed aft of last stage turbine/forward of exhaust nozzle

- Contain fuel manifold, an ignition source, and a flame holder

Afterburner Function

- Operated because gases in tailpipe contain oxygen

- 25% 75% discharge used for cooling support combustion

- A fuel manifold fits the tailpipe entrance, fuel injects fuel into the tailpipe

- The fuel and air mix, ignite and burn in the afterburner

- Additional heat accelerates the exhaust gases

Flame Holder

- Tubular grid/spoke-shaped obstruction

- It is placed downstream of the fuel nozzles for fuel and air mixing

- Causes turbulence, gases swirl

Afterburner Influence

- Increases temperature/thrust

- Exhaust nozzle area increased to the decreased back pressure

- Increasing exhaust size controls exhaust gas temperature

Afterburning

- Used to increase thrust on for military aircraft

- It can provide as much as a 100% increase in thrust with fuel flows three to five times higher

Thrust Reversers

- Assist in braking

- Redirect exhaust gases to provide thrust in opposite direction

Accessory Section

- Powers engine and aircraft accessories (electric generators, hydraulic pumps, fuel pumps, and oil pumps)

- Acting as an oil reservoir or sump

- Housing accessory drive gears/reduction gears

- Accessory drive location selected to minimize engine profile for streamlining

Power for Accessories

- From the engine's main power shaft

- Beveled gears drive an accessory shaft, then, an accessory gearbox

- The gearbox then distributes power to each accessory drive pad

- Turbine engines require the use of rpm reduction

- Some installations require an intermediate or transfer gearbox for appropriate reduction gearing

Engine Stations Numbering

- Locate certain engine areas when doing maintenance

- Numbers in the same area take in temperature and pressure

- Identifies EPR reading because engines have different ducts

Station Numbering for instruments

- P refers to pressure

- T refers to temperature

Noise Suppression

- Some energy released from burning fuel turns into noise pollution

- Noise pollution is a big issue that impacts both designers and operators

- Noise reduced by mixing fast gasses with slow gas

- Use of turbofans helps lower both inside and on-ground noise

- Turbofans do not suppress noise because exhaust cancels it internally

Turbine noise

- In older planes require devices that disrupt airflow behind the tailcone with soundproof material

- The sound intensity is measured in decibels (db)

- A decibel is the ratio of one sound to another.

- 60 db is good 130db is physically dangerous

Airport Concerns

- Federal Aviation Administration has established noise limits based on an aircraft weight for airport

- All older aircraft were granted the period of time for adjustments

Engine Mounts

- Design and construction is simple

- Turbine engines produce little torque, only need to support the weight of the aircraft and protect from stress

- A wing-mounted engine is mounted to two or four brackets

- Turboprops produce larger torque and propeller weights

- Turboshafts use stronger locations for many mounts

Bearings

- Support engines

- Located lengthwise

- Number depends on the rotor weight

- Split-spool usually more than 1

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.