Podcast

Questions and Answers

What is the primary function of the combustion section in a gas turbine engine?

What is the primary function of the combustion section in a gas turbine engine?

- To compress air for combustion

- To add heat energy to the flowing gases (correct)

- To cool the engine components

- To generate electricity

What is the result of adding fuel heat in the combustion process?

What is the result of adding fuel heat in the combustion process?

- A decrease in gas volume

- No change in gas volume

- An increase in gas volume (correct)

- A change in gas pressure only

What is the purpose of the fuel drainage system in the combustion section?

What is the purpose of the fuel drainage system in the combustion section?

- To ignite the fuel in the combustors

- To cool the engine components

- To drain unburned fuel after engine shutdown (correct)

- To inject fuel into the combustors

What type of system is typically used as an ignition source in the combustion section?

What type of system is typically used as an ignition source in the combustion section?

What is the primary goal of a combustion chamber in a gas turbine engine?

What is the primary goal of a combustion chamber in a gas turbine engine?

What is the effect of the perforations in the inner liner of the combustion chamber?

What is the effect of the perforations in the inner liner of the combustion chamber?

What is the process referred to when fuel heat is added and the volume of the gas increases, causing an acceleration of gases to occur?

What is the process referred to when fuel heat is added and the volume of the gas increases, causing an acceleration of gases to occur?

What is a major consideration when designing a combustion chamber?

What is a major consideration when designing a combustion chamber?

How many basic types of combustion chambers are currently used?

How many basic types of combustion chambers are currently used?

What is a characteristic of the multiple-can type combustion chamber?

What is a characteristic of the multiple-can type combustion chamber?

What is a benefit of the inner liner in a multiple-can combustor?

What is a benefit of the inner liner in a multiple-can combustor?

What is a disadvantage of the multiple-can type combustion chamber?

What is a disadvantage of the multiple-can type combustion chamber?

What is the primary function of the reverse-flow annular combustor?

What is the primary function of the reverse-flow annular combustor?

What percentage of the incoming air is designated as primary in a combustor?

What percentage of the incoming air is designated as primary in a combustor?

What is the purpose of the swirl vanes in the primary combustion air?

What is the purpose of the swirl vanes in the primary combustion air?

What is the result of the airflow passing through the swirl vanes?

What is the result of the airflow passing through the swirl vanes?

What is the purpose of the primary combustion air?

What is the purpose of the primary combustion air?

What is the advantage of the reverse-flow combustor design?

What is the advantage of the reverse-flow combustor design?

What is the purpose of the toroidal vortex in the combustion section?

What is the purpose of the toroidal vortex in the combustion section?

What is the approximate percentage of primary airflow in relation to total airflow?

What is the approximate percentage of primary airflow in relation to total airflow?

What is the result of a lean air-fuel mixture in the combustion process?

What is the result of a lean air-fuel mixture in the combustion process?

What is the purpose of the secondary airflow in the combustion section?

What is the purpose of the secondary airflow in the combustion section?

What is the term for a perfectly balanced air-fuel mixture?

What is the term for a perfectly balanced air-fuel mixture?

What is the range of combustible air-fuel ratios?

What is the range of combustible air-fuel ratios?

What is an advantage of the can-annular combustor design?

What is an advantage of the can-annular combustor design?

What is a characteristic of the annular combustor?

What is a characteristic of the annular combustor?

What is a benefit of the annular combustor design?

What is a benefit of the annular combustor design?

How many spark igniters are typically used in an annular combustor?

How many spark igniters are typically used in an annular combustor?

What is a disadvantage of the annular combustor design?

What is a disadvantage of the annular combustor design?

What is the airflow path in an annular combustor?

What is the airflow path in an annular combustor?

Flashcards are hidden until you start studying

Study Notes

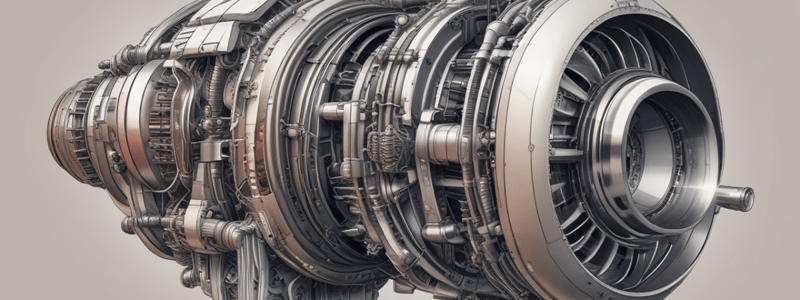

Combustion Section

- Located between the compressor diffuser and turbine section

- Contains: combustion chambers (combustors or cans), fuel injection system, ignition source, and fuel drainage system

Combustion Chamber

- Where fuel and air are mixed and burned

- Fuel injection system supplies fuel through fuel nozzles

- Ignition source: high-energy capacitor discharge system

- Fuel drainage system: drains unburned fuel after engine shutdown

- Function: adds heat energy to flowing gases, expanding and accelerating them into the turbine section

Combustion Process

- When fuel heat is added, gas volume increases, causing acceleration of gases

- Process referred to as combustion at constant pressure

- To efficiently burn fuel/air mixture, combustion chamber must:

- Mix fuel and air effectively in the best ratio for good combustion

- Burn the mixture efficiently and quickly

- Cool hot combustion gases to a temperature the turbine blades can tolerate

- Distribute hot gases evenly to the turbine section

Types of Combustion Chambers

- Multiple-can

- Can/annular

- Annular

- Functionally the same, but design and construction differ

Multiple-Can Combustor

- Consists of a series of individual combustor cans

- Well suited for centrifugal compressor engines

- Each can has a perforated stainless steel liner inside the outer case

- Inner liner is highly heat resistant and easily removable for inspection

- Advantages: easy on-the-wing maintenance, uniform temperature at the turbine

Can-Annular Combustion Chamber

- Components: housing, perforated inner liner, and shroud

- Can be shaped to contain one or more concentric baskets

- Ignition source: two spark igniters

Annular Combustor

- Most efficient, with a shorter length than multiple-can systems for the same power output

- Consists of a housing and a perforated inner liner

- Liner is a single unit that encircles the outside of the turbine shaft housing

Reverse-Flow Annular Combustor

- Airflow can reverse direction

- Combustion gases flow in the opposite direction of the normal airflow through the engine

- Turbine wheels are inside the combustor area rather than downstream

- Advantages: shorter and lighter engine

Combustion Airflow

- Divided into primary and secondary paths

- Primary combustion air: 20%–30% of incoming air, directed inside the liner in the front end of a combustor

- Secondary airflow: 70%–80% of incoming air, flows at a velocity of several hundred feet per second around the combustor's periphery

Primary Combustion Air

- Passes through swirl vanes, giving the air a radial motion and slowing down its axial velocity to 5–6 ft/s

- Toroidal vortex created in the flame area provides turbulence to mix fuel and air

- Combustion process is complete in the first third of a combustor

Secondary Airflow

- Forms a cooling air blanket on both sides of the liner and centers the combustion flames

- Some secondary air is slowed and metered into the combustor through perforations in the liner

- Ensures combustion of any remaining unburned fuel

- Mixes with burned gases and cools the air to evenly distribute energy to the turbine nozzle

Combustion Air / Fuel Ratio

- Liquid fuels must be converted from liquid to vapor before they will burn

- Stoichiometric mixture: 15 parts air to one part fuel by weight

- Combustible air-fuel ratios: 8:1 to 22:1

- Often expressed as 60:1, which refers to total airflow rather than primary combustor airflow

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.