Zettelkasten: Engineering Notes

Document Details

Uploaded by AccomplishedRationality7836

Tags

Related

- Engineering Mathematics 1 19MA1ICMAT Module 1- Linear Algebra PDF

- Mathematics-I PDF - B.Tech 1st Year

- Karnavati University Engineering Mathematics Past Paper 2024-2025 PDF

- Engineering Mathematics I Past Paper PDF - MAT 1151 - 2018

- Final Question Bank (Engg Mathematics) PDF

- Wiley Acing the GATE: Engineering Mathematics and General Aptitude PDF

Summary

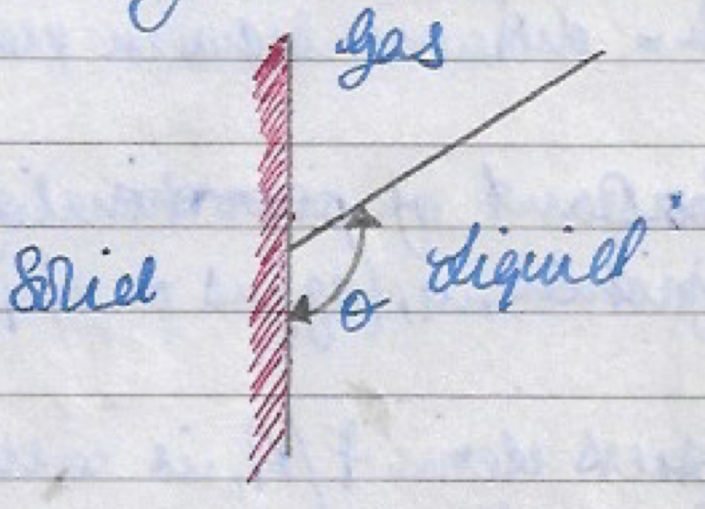

These notes cover various engineering topics, including linear algebra, focusing on subspaces and their properties. They also discuss stress-strain diagrams, header tanks, and compression, providing equations and diagrams. Material behavior under load is emphasized in this compendium of notes.

Full Transcript

- Linear Algebra - Subspaces 🧾 #[[0 - Engineering Mathematics]] #[[Linear Algebra]] #Subspaces - Subspace↔Vector space that is a [Subset](undefined.md) of another vector space - Criteria for checking a vector space is a [Subspace](undefined.md) of another vector space?>>>...