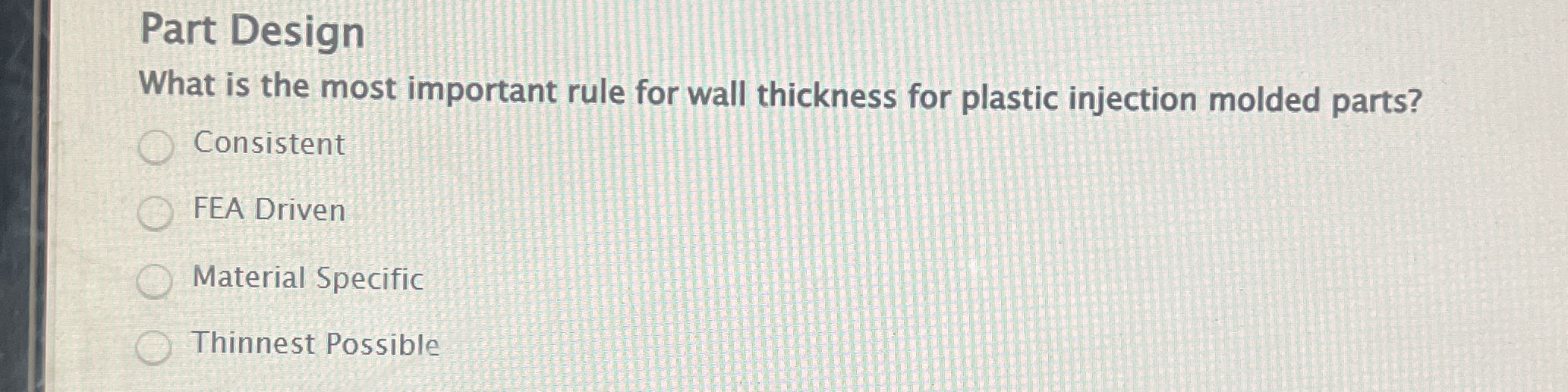

What is the most important rule for wall thickness for plastic injection molded parts?

Understand the Problem

The question is asking about the most important rule for wall thickness when designing plastic injection molded parts. It presents four options: Consistent, FEA Driven, Material Specific, and Thinnest Possible. We need to determine which of these options is generally considered the most critical rule for wall thickness in this context.

Answer

Consistent wall thickness.

The most important rule is that wall thickness should be consistent.

Answer for screen readers

The most important rule is that wall thickness should be consistent.

More Information

Maintaining consistent wall thickness helps prevent issues like warping and ensures even cooling during the injection molding process.

Tips

A common mistake is designing parts with drastically varying wall thicknesses, leading to uneven cooling and potential structural weaknesses.

Sources

AI-generated content may contain errors. Please verify critical information