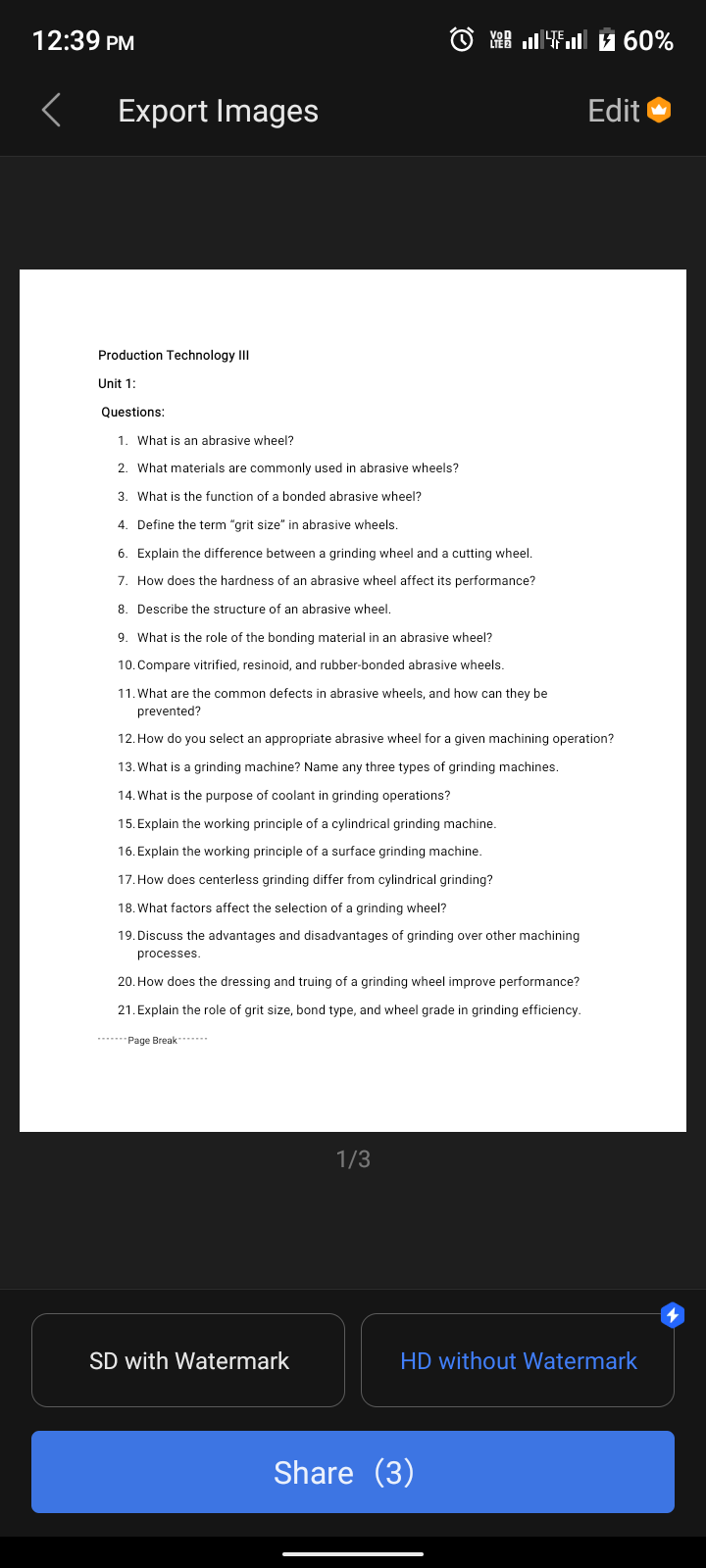

What is an abrasive wheel? What materials are commonly used in abrasive wheels? What is the function of a bonded abrasive wheel? Define the term 'grit size' in abrasive wheels. Exp... What is an abrasive wheel? What materials are commonly used in abrasive wheels? What is the function of a bonded abrasive wheel? Define the term 'grit size' in abrasive wheels. Explain the difference between a grinding wheel and a cutting wheel. How does the hardness of an abrasive wheel affect its performance? Describe the structure of an abrasive wheel. What is the role of the bonding material in an abrasive wheel? Compare vitrified, resinoid, and rubber-bonded abrasive wheels. What are the common defects in abrasive wheels, and how can they be prevented? How do you select an appropriate abrasive wheel for a given machining operation? What is a grinding machine? Name any three types of grinding machines. What is the purpose of coolant in grinding operations? Explain the working principle of a cylindrical grinding machine. Explain the working principle of a surface grinding machine. How does centerless grinding differ from cylindrical grinding? What factors affect the selection of a grinding wheel? Discuss the advantages and disadvantages of grinding over other machining processes. How does the dressing and truing of a grinding wheel improve performance? Explain the role of grit size, bond type, and wheel grade in grinding efficiency.

Understand the Problem

The image contains a set of questions related to abrasive wheels, grinding machines, and grinding processes. These questions are asking us to define terms, compare different types of wheels, explain working principles, and discuss factors that affect the selection and performance of grinding wheels.

Answer

Answers to questions regarding abrasive wheels, grinding machines, and grinding operations, including definitions, materials, functions, and selection criteria.

Here are the answers to the questions regarding Production Technology III:

- An abrasive wheel is a cutting tool made of abrasive particles held together by a bonding material.

- Common materials used in abrasive wheels are abrasive grains and bonding agents.

- The function of a bonded abrasive wheel is to help shape and refine materials.

- Grit size refers to the size of the abrasive particles in the wheel.

- A grinding wheel is used for precision material removal, while a cutting wheel is designed for severing materials.

- The hardness of an abrasive wheel affects its material removal rate and wheel life.

- An abrasive wheel consists of abrasive grains, a bonding agent, and air/empty space.

- The bonding material holds the abrasive grains together.

- Vitrified wheels are rigid and strong; resinoid wheels offer more flexibility; rubber-bonded wheels provide a smooth finish.

- Common defects include cracking and imbalance, which can be prevented through proper handling and storage.

- Selection depends on the material, the amount of material to be removed, and the desired finish.

- A grinding machine is a power tool used for grinding. Three types are: cylindrical, surface, and centerless grinding machines.

- Coolant reduces heat, lubricates, and removes debris during grinding.

- Cylindrical grinding involves rotating the workpiece and the grinding wheel to grind the outer or inner diameter of a cylinder.

- Surface grinding involves moving a flat workpiece under a rotating grinding wheel to create a smooth, flat surface.

- Centerless grinding supports the workpiece without centers, allowing for continuous grinding, whereas cylindrical grinding uses centers to support the workpiece.

- Factors include material hardness, grinding wheel speed, and desired surface finish.

- Advantages include high precision and good surface finish; disadvantages include low material removal rates.

- Dressing and truing sharpen the wheel and restore its shape, improving cutting ability and accuracy.

- Grit size, bond type, and wheel grade determine the wheel's material removal rate, ability to hold shape, and overall grinding efficiency.

Answer for screen readers

Here are the answers to the questions regarding Production Technology III:

- An abrasive wheel is a cutting tool made of abrasive particles held together by a bonding material.

- Common materials used in abrasive wheels are abrasive grains and bonding agents.

- The function of a bonded abrasive wheel is to help shape and refine materials.

- Grit size refers to the size of the abrasive particles in the wheel.

- A grinding wheel is used for precision material removal, while a cutting wheel is designed for severing materials.

- The hardness of an abrasive wheel affects its material removal rate and wheel life.

- An abrasive wheel consists of abrasive grains, a bonding agent, and air/empty space.

- The bonding material holds the abrasive grains together.

- Vitrified wheels are rigid and strong; resinoid wheels offer more flexibility; rubber-bonded wheels provide a smooth finish.

- Common defects include cracking and imbalance, which can be prevented through proper handling and storage.

- Selection depends on the material, the amount of material to be removed, and the desired finish.

- A grinding machine is a power tool used for grinding. Three types are: cylindrical, surface, and centerless grinding machines.

- Coolant reduces heat, lubricates, and removes debris during grinding.

- Cylindrical grinding involves rotating the workpiece and the grinding wheel to grind the outer or inner diameter of a cylinder.

- Surface grinding involves moving a flat workpiece under a rotating grinding wheel to create a smooth, flat surface.

- Centerless grinding supports the workpiece without centers, allowing for continuous grinding, whereas cylindrical grinding uses centers to support the workpiece.

- Factors include material hardness, grinding wheel speed, and desired surface finish.

- Advantages include high precision and good surface finish; disadvantages include low material removal rates.

- Dressing and truing sharpen the wheel and restore its shape, improving cutting ability and accuracy.

- Grit size, bond type, and wheel grade determine the wheel's material removal rate, ability to hold shape, and overall grinding efficiency.

More Information

Abrasive wheels are essential tools in manufacturing, offering precision and control in material removal. Understanding their composition, function, and maintenance is crucial for efficient and safe grinding operations.

Tips

A common mistake is using the wrong type of abrasive wheel for a specific material or operation, which can lead to poor results or damage to the workpiece or grinding machine. Always consult the manufacturer's guidelines and select the appropriate wheel for the job.

Sources

- What is an Abrasive Wheel and its Types - benchmarkabrasives.com

- Bonded vs. Coated | Types of Abrasives Used in Grinding Wheels - dxpe.com

- Grinding Wheel Basics – What's in a Wheel - Norton Abrasives - nortonabrasives.com

AI-generated content may contain errors. Please verify critical information