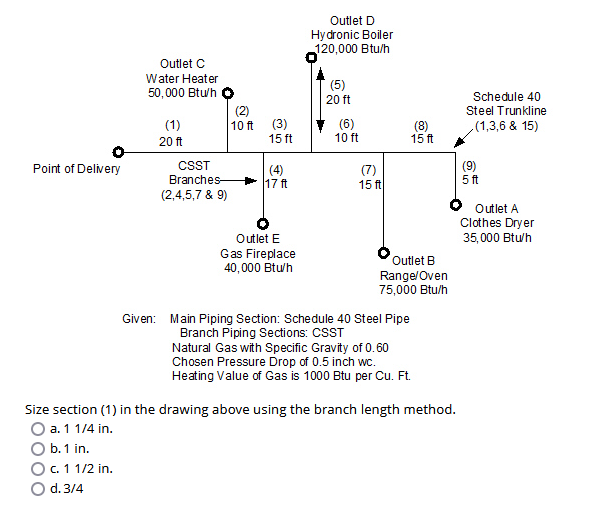

Size section (1) in the drawing above using the branch length method.

Understand the Problem

The question is asking for the size of section (1) in the provided piping diagram using the branch length method for gas piping systems, taking into account various parameters such as pressure drop and gas heating value.

Answer

The size for section (1) is $1 \frac{1}{4}$ in.

Answer for screen readers

The appropriate size for section (1) is $1 \frac{1}{4}$ in.

Steps to Solve

- Identify Total Demand First, calculate the total gas demand from all outlets. The demand for each outlet is:

- Outlet C: 50,000 Btu/h

- Outlet D: 120,000 Btu/h

- Outlet E: 40,000 Btu/h

- Outlet B: 75,000 Btu/h

- Outlet A: 35,000 Btu/h

Total demand is calculated as: $$ \text{Total Demand} = 50,000 + 120,000 + 40,000 + 75,000 + 35,000 = 320,000 , \text{Btu/h} $$

- Convert to Equivalent Length Using the Branch Length Method Use the given lengths of each section, considering their branch characteristics:

- Consider lengths:

- To Outlet C: 20 ft (1)

- To Outlet D: 20 ft (5)

- To Outlet E: 17 ft (4)

- To Outlet B: 15 ft (7)

- To Outlet A: 5 ft (9)

For a gas pipe system, calculate the total equivalent length by summing the actual lengths and applying the correction factor based on the fittings used (usually provided in engineering tables, or can be approximated).

- Determine Pressure Drop and Use Size Chart Using the pressure drop of 0.5 inch wc and the heating value of 1000 Btu/cubic foot, consult a piping size chart or use the provided method to determine the required pipe sizing.

Convert the total equivalent demand (320,000 Btu/h) to flow rate in cubic feet per hour: $$ \text{Flow rate} = \frac{\text{Total Demand}}{\text{Heating Value}} = \frac{320,000, \text{Btu/h}}{1000, \text{Btu/cubic ft}} = 320, \text{cubic ft/h} $$

- Select Appropriate Pipe Size Based on the calculated flow rate and considering the calculated equivalent length and pressure drop, determine the appropriate CSST size from pipe sizing tables.

In this case, options provided include:

- a. 1 1/4 in.

- b. 1 in.

- c. 1 1/2 in.

- d. 3/4 in.

- Choosing the Best Size Review the sizing tables based on the calculated values to find out which of the options can carry the 320 cubic ft/h safely given the pressure drop criteria.

The appropriate size for section (1) is $1 \frac{1}{4}$ in.

More Information

The decision to use $1 \frac{1}{4}$ in size is based on the total demand of 320,000 Btu/h and the calculated pressure drop across the branches. Generally, larger pipe sizes facilitate less pressure drop and allow for greater flow, thus optimizing the gas delivery system.

Tips

- Failing to include all outlet demands in the total calculation.

- Overlooking the correction factors for fittings when calculating equivalent lengths.

- Not consulting the pressure drop charts accurately or misinterpreting the tables.

AI-generated content may contain errors. Please verify critical information