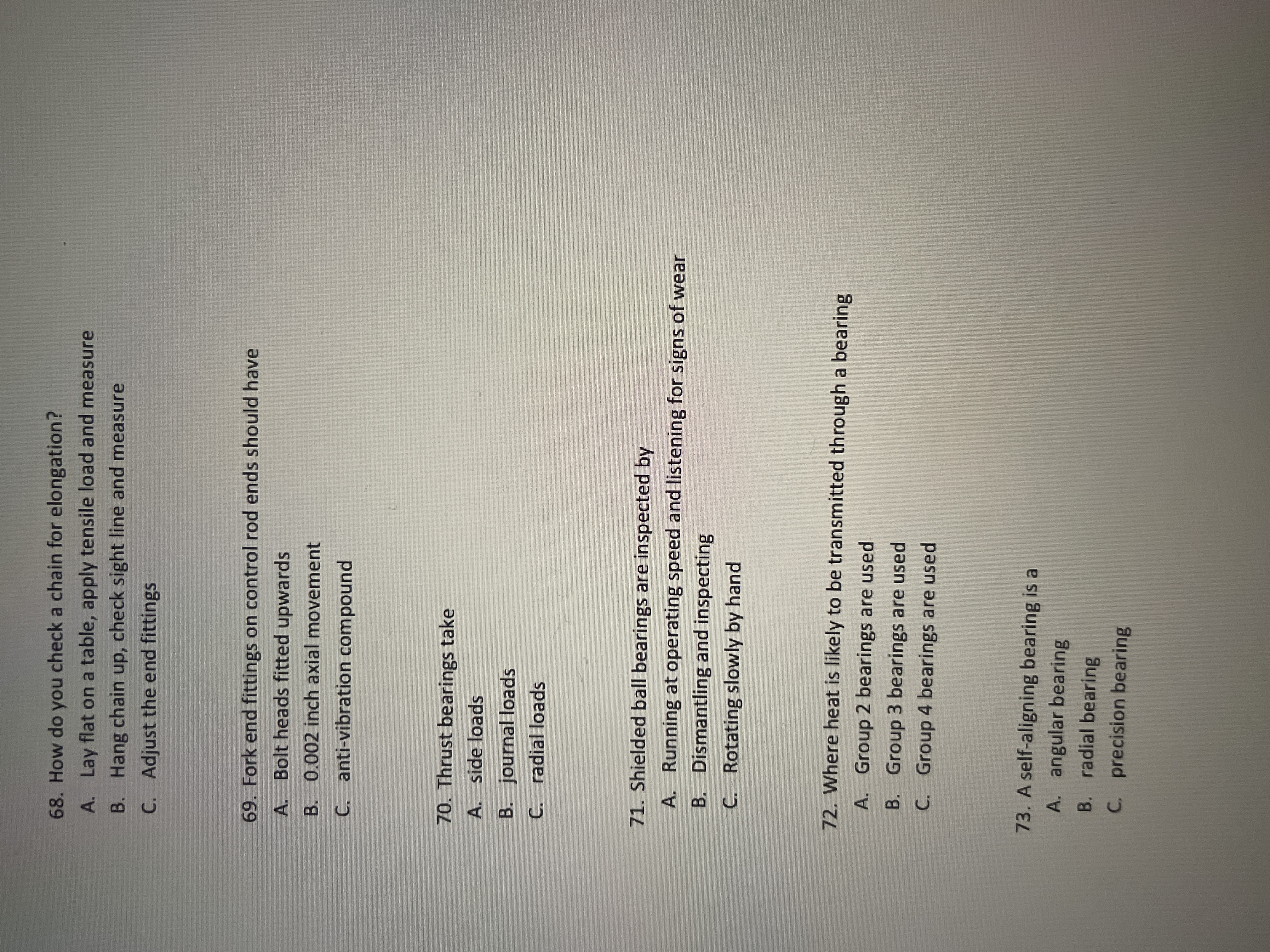

How do you check a chain for elongation? Fork end fittings on control rod ends should have what? What loads do thrust bearings take? How are shielded ball bearings inspected? Where... How do you check a chain for elongation? Fork end fittings on control rod ends should have what? What loads do thrust bearings take? How are shielded ball bearings inspected? Where is heat likely to be transmitted through a bearing? What is a self-aligning bearing?

Understand the Problem

The question concerns various mechanical engineering concepts related to checking chains, fork end fittings, thrust bearings, and bearing inspections. It is assessing knowledge of these technical topics.

Answer

68: Lay flat on table and measure. 69: 0.002 inch axial movement. 70: Journal loads. 71: Operating speed inspection. 72: Group 4 bearings. 73: Radial bearing.

- How do you check a chain for elongation? Lay flat on a table, apply tensile load and measure. 69. Fork end fittings on control rod ends should have 0.002 inch axial movement. 70. Thrust bearings take journal loads. 71. Shielded ball bearings are inspected by running at operating speed and listening for signs of wear. 72. Where heat is likely to be transmitted through a bearing, Group 4 bearings are used. 73. A self-aligning bearing is a radial bearing.

Answer for screen readers

- How do you check a chain for elongation? Lay flat on a table, apply tensile load and measure. 69. Fork end fittings on control rod ends should have 0.002 inch axial movement. 70. Thrust bearings take journal loads. 71. Shielded ball bearings are inspected by running at operating speed and listening for signs of wear. 72. Where heat is likely to be transmitted through a bearing, Group 4 bearings are used. 73. A self-aligning bearing is a radial bearing.

More Information

Checking a chain for elongation by laying it flat allows for accurate measurements under tension. Thrust bearings handle axial loads. Shielded bearings are best inspected under operational conditions. Self-aligning bearings accommodate misalignment and are often radial bearings.

Tips

Ensure accurate measurements with tension when checking chain elongation. Misalignment in thrust bearings can result in increased wear.

Sources

AI-generated content may contain errors. Please verify critical information