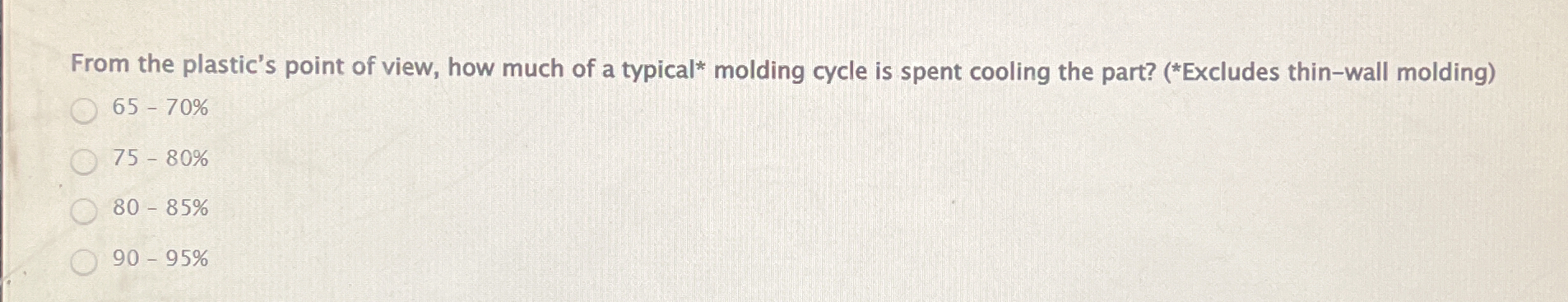

From the plastic's point of view, how much of a typical molding cycle is spent cooling the part? (Excludes thin-wall molding)

Understand the Problem

The question pertains to the plastic molding process, asking what percentage of a typical molding cycle is dedicated to cooling the part, specifically from the perspective or viewpoint of the plastic material itself. The question excludes thin-wall molding processes.

Answer

80-85% of a typical molding cycle is spent cooling the part.

The final answer is 80-85%

Answer for screen readers

The final answer is 80-85%

More Information

Cooling time is a critical aspect of the injection molding process, as it directly impacts the part's quality and cycle time. Optimizing cooling time can lead to increased production efficiency and reduced costs.

Tips

A common mistake is assuming that thin-wall molding has the same cooling time percentage as standard molding.

Sources

- Injection Molding Cooling Time: A Breakdown - Design World - designworldonline.com

- Injection molding: The manufacturing & design guide - hubs.com

- Cooling Rate in Injection Molding: A Comprehensive Guide - hansenplastics.com

AI-generated content may contain errors. Please verify critical information