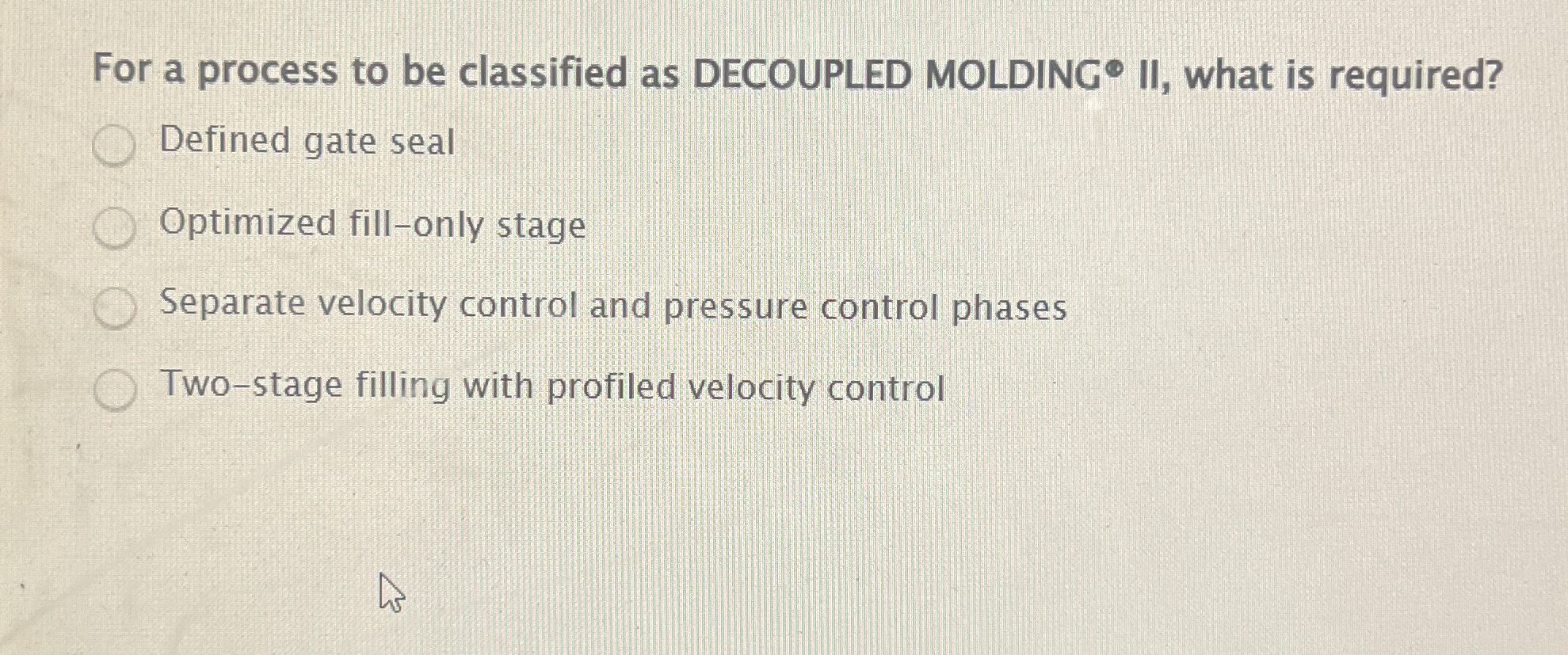

For a process to be classified as DECOUPLED MOLDING II, what is required?

Understand the Problem

The question is asking what is required for a process to be classified as DECOUPLED MOLDING II. We need to identify the key characteristics or conditions that define this specific molding process, and select the correct statement from the options provided.

Answer

The process requires separation of the injection molding cycle into two distinct stages: filling and packing.

For a process to be classified as DECOUPLED MOLDING II, the process requires separation of the injection molding cycle into two distinct stages: filling and packing.

Answer for screen readers

For a process to be classified as DECOUPLED MOLDING II, the process requires separation of the injection molding cycle into two distinct stages: filling and packing.

More Information

Decoupled molding II separates the filling and packing stages to optimize control and consistency. This method helps minimize variations and improve part quality.

Tips

A common mistake is to confuse decoupled molding I and II. Decoupled molding I focuses on a defined gate seal, whereas decoupled molding II focuses on separating filling and packing stages.

Sources

- What is Decoupled Injection Molding? - crescentind.com

AI-generated content may contain errors. Please verify critical information