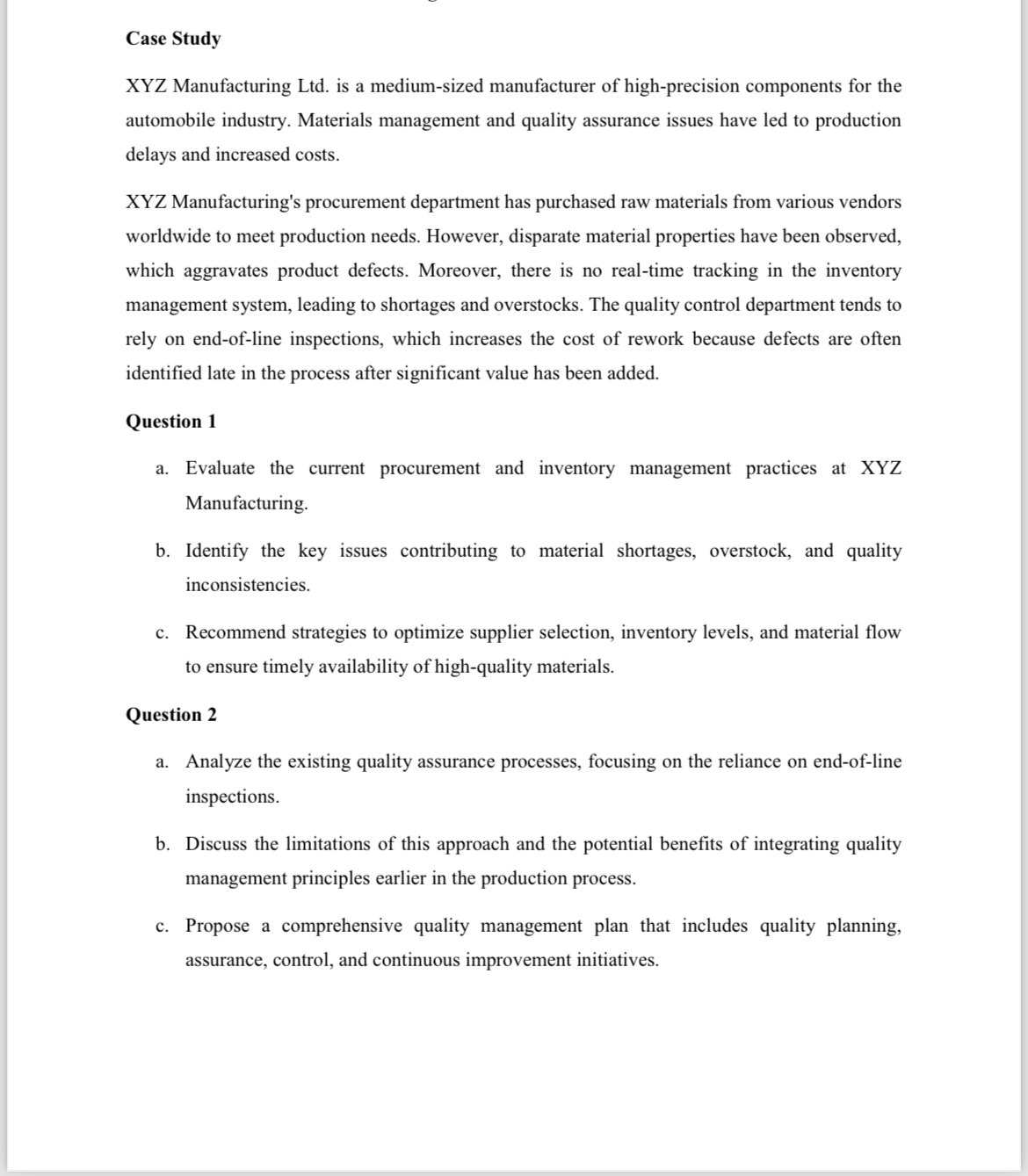

Analyze the case study of XYZ Manufacturing Ltd. and answer the following questions: 1. a. Evaluate the current procurement and inventory management practices at XYZ Manufacturing.... Analyze the case study of XYZ Manufacturing Ltd. and answer the following questions: 1. a. Evaluate the current procurement and inventory management practices at XYZ Manufacturing. b. Identify the key issues contributing to material shortages, overstock, and quality inconsistencies. c. Recommend strategies to optimize supplier selection, inventory levels, and material flow to ensure timely availability of high-quality materials. 2. a. Analyze the existing quality assurance processes, focusing on the reliance on end-of-line inspections. b. Discuss the limitations of this approach and the potential benefits of integrating quality management principles earlier in the production process. c. Propose a comprehensive quality management plan that includes quality planning, assurance, control, and continuous improvement initiatives.

Understand the Problem

The question presents a case study of XYZ Manufacturing Ltd., a medium-sized manufacturer in the automobile industry facing challenges related to materials management, quality assurance, and procurement. It asks to evaluate current practices, identify key issues contributing to material shortages and quality inconsistencies, and recommend strategies for improvement. Furthermore, it requires analyzing existing quality assurance processes, discussing the limitations of relying on end-of-line inspections, and proposing a comprehensive quality management plan.

Answer

The case study questions related to procurement, inventory management, and quality assurance for XYZ Manufacturing Ltd. are analyzed and answered.

Here is the answer to the case study questions:

Question 1

a. Evaluation of current practices:

- Procurement: XYZ Manufacturing sources raw materials from various vendors worldwide. This approach has led to inconsistent material properties, increasing product defects.

- Inventory Management: The lack of real-time tracking in the inventory management system results in material shortages and overstocks.

b. Key Issues:

- Material Shortages: Lack of real-time tracking, poor demand forecasting.

- Overstock: Inefficient inventory management leading to excess stock of some materials.

- Quality Inconsistencies: Sourcing from multiple vendors leads to variations in raw material properties.

c. Recommended Strategies:

- Supplier Selection: Implement a rigorous supplier selection process based on quality, reliability, and cost.

- Inventory Levels: Use methods like Just-In-Time (JIT) manufacturing to reduce inventory-related costs.

- Material Flow: Implement real-time tracking in the inventory management system.

Question 2

a. Analysis of existing quality assurance processes:

- XYZ Manufacturing relies on end-of-line inspections to ensure product quality.

b. Limitations and benefits of integrating quality management principles:

- Limitations: Defects are identified late in the process.

- Benefits: Integrating quality management principles earlier in the production process can prevent defects.

c. Proposed quality management plan:

- Quality Planning: Define quality standards and metrics.

- Quality Assurance: Implement process controls.

- Quality Control: Monitor and measure quality performance.

- Continuous Improvement: Implement DMAIC (Define, Measure, Analyze, Improve, Control) methodology to address the identified issues.

Answer for screen readers

Here is the answer to the case study questions:

Question 1

a. Evaluation of current practices:

- Procurement: XYZ Manufacturing sources raw materials from various vendors worldwide. This approach has led to inconsistent material properties, increasing product defects.

- Inventory Management: The lack of real-time tracking in the inventory management system results in material shortages and overstocks.

b. Key Issues:

- Material Shortages: Lack of real-time tracking, poor demand forecasting.

- Overstock: Inefficient inventory management leading to excess stock of some materials.

- Quality Inconsistencies: Sourcing from multiple vendors leads to variations in raw material properties.

c. Recommended Strategies:

- Supplier Selection: Implement a rigorous supplier selection process based on quality, reliability, and cost.

- Inventory Levels: Use methods like Just-In-Time (JIT) manufacturing to reduce inventory-related costs.

- Material Flow: Implement real-time tracking in the inventory management system.

Question 2

a. Analysis of existing quality assurance processes:

- XYZ Manufacturing relies on end-of-line inspections to ensure product quality.

b. Limitations and benefits of integrating quality management principles:

- Limitations: Defects are identified late in the process.

- Benefits: Integrating quality management principles earlier in the production process can prevent defects.

c. Proposed quality management plan:

- Quality Planning: Define quality standards and metrics.

- Quality Assurance: Implement process controls.

- Quality Control: Monitor and measure quality performance.

- Continuous Improvement: Implement DMAIC (Define, Measure, Analyze, Improve, Control) methodology to address the identified issues.

More Information

The proposed quality management plan includes quality planning, assurance, control, and continuous improvement initiatives using the DMAIC methodology.

Tips

Consider all aspects of the case study when formulating your answer. Use information and context from the case study.

Sources

- Solved Read the case study first. Then, answer all the | Chegg.com - chegg.com

- Solved Case Study: XYZ Manufacturing Company - Improving - Chegg - chegg.com

- Six Sigma Test Questions (90 Exam Samples) [2025/26] - sixsigma-institute.org

AI-generated content may contain errors. Please verify critical information