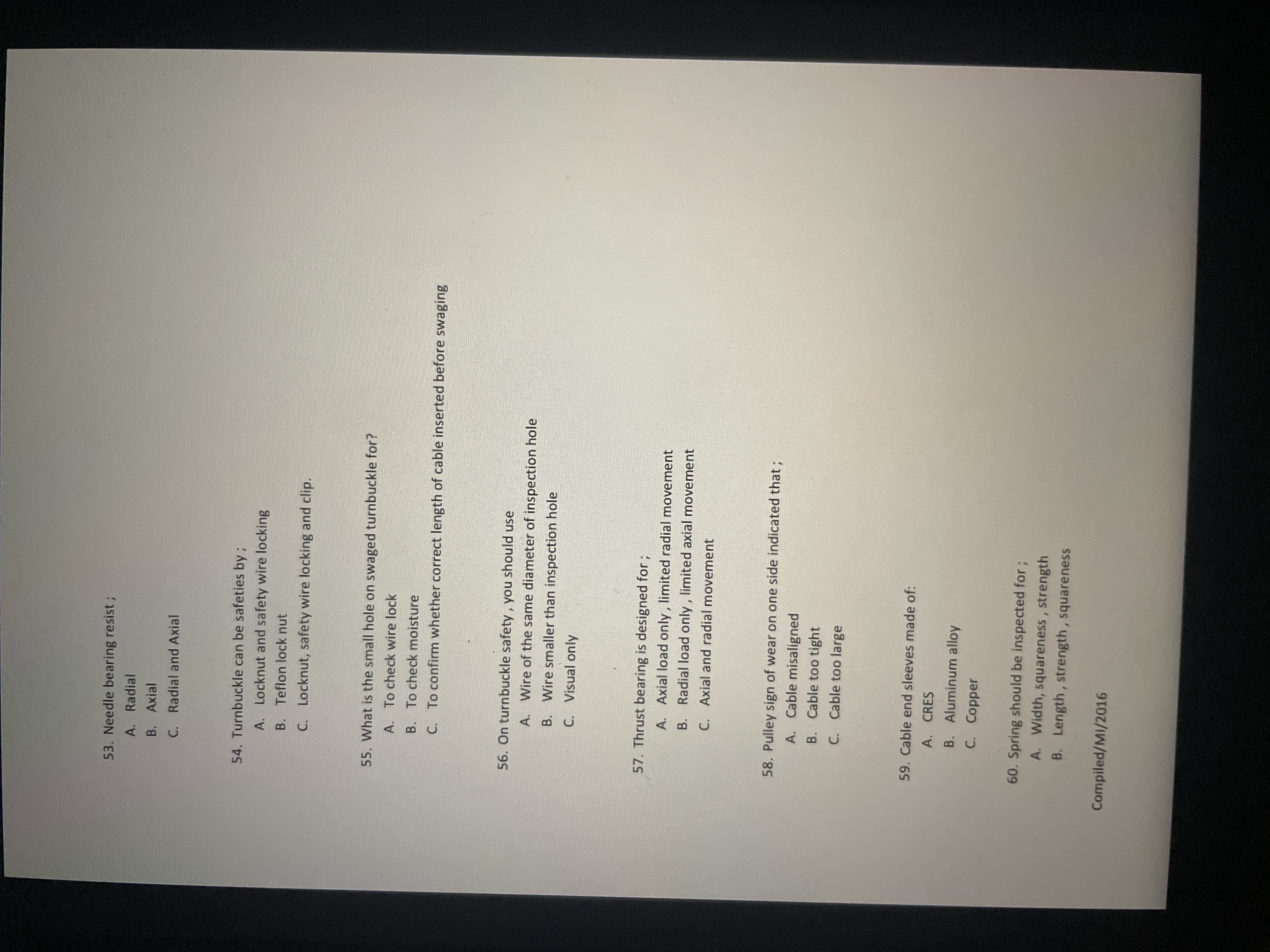

1. What type of bearing resists axial and radial loads? 2. What safety measures can be applied to a turnbuckle? 3. What is the purpose of the small hole on a swaged turnbuckle? 4.... 1. What type of bearing resists axial and radial loads? 2. What safety measures can be applied to a turnbuckle? 3. What is the purpose of the small hole on a swaged turnbuckle? 4. What type of wire should be used for turnbuckle safety? 5. What design is a thrust bearing made for? 6. What does wear on one side of a pulley indicate? 7. What material are cable end sleeves typically made from? 8. What aspects should a spring be inspected for?

Understand the Problem

The questions are focused on various technical aspects of mechanical engineering, specifically concerning components such as needle bearings, turnbuckles, thrust bearings, pulleys, cable sleeves, and springs.

Answer

1. Taper roller bearings 2. Locknut, safety wire locking, clip 3. Confirm cable length 4. Wire same diameter 5. Axial loads 6. Cable misaligned 7. Aluminum alloy 8. Width, squareness, strength

- Taper roller bearings resist axial and radial loads. 2. Turnbuckles can be made safe with locknut, safety wire locking, and clip. 3. The small hole on a swaged turnbuckle is to confirm correct length of cable. 4. Use wire of the same diameter as the inspection hole for turnbuckle safety. 5. Thrust bearings are designed for axial loads with limited radial movement. 6. Wear on one side of a pulley indicates cable misalignment. 7. Cable end sleeves are typically made from aluminum alloy. 8. Springs should be inspected for width, squareness, and strength.

Answer for screen readers

- Taper roller bearings resist axial and radial loads. 2. Turnbuckles can be made safe with locknut, safety wire locking, and clip. 3. The small hole on a swaged turnbuckle is to confirm correct length of cable. 4. Use wire of the same diameter as the inspection hole for turnbuckle safety. 5. Thrust bearings are designed for axial loads with limited radial movement. 6. Wear on one side of a pulley indicates cable misalignment. 7. Cable end sleeves are typically made from aluminum alloy. 8. Springs should be inspected for width, squareness, and strength.

More Information

Taper roller bearings are versatile for handling combined loads. Turnbuckles have multiple safety measures to ensure proper tensioning and alignment. Proper inspection and materials are crucial for safety and functionality in mechanical systems.

Tips

Confusing thrust and radial bearings; ensure to match bearing type with load requirements.

Sources

- Module 6 | PDF | Rivet | Corrosion - Scribd - scribd.com

- Module 06. Materials & Hardware - Aviation Read - aviationread.com

AI-generated content may contain errors. Please verify critical information