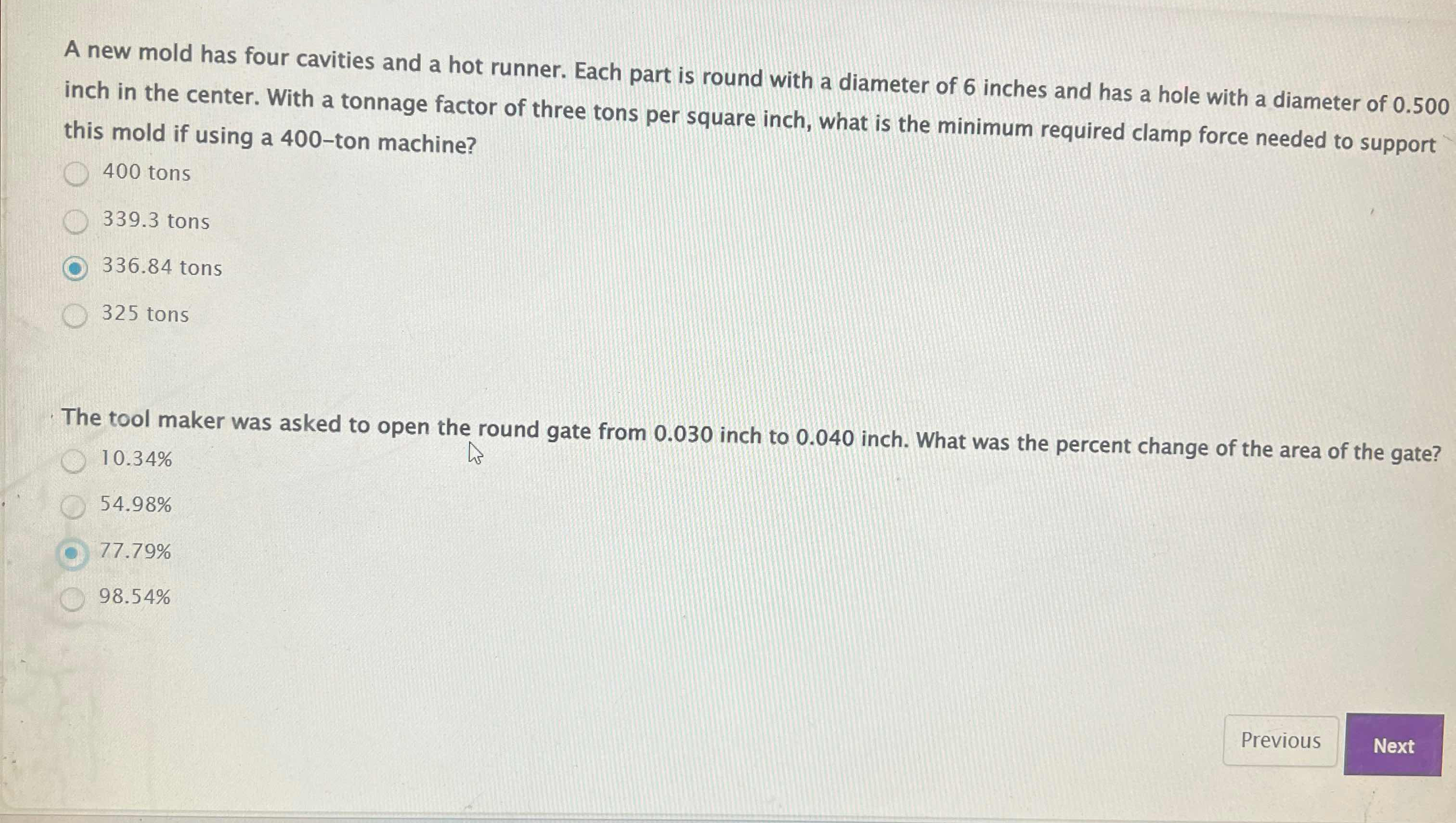

1. A new mold has four cavities and a hot runner. Each part is round with a diameter of 6 inches and has a hole with a diameter of 0.500 inch in the center. With a tonnage factor o... 1. A new mold has four cavities and a hot runner. Each part is round with a diameter of 6 inches and has a hole with a diameter of 0.500 inch in the center. With a tonnage factor of three tons per square inch, what is the minimum required clamp force needed to support this mold if using a 400-ton machine? 2. The tool maker was asked to open the round gate from 0.030 inch to 0.040 inch. What was the percent change of the area of the gate?

Understand the Problem

There are two questions. The first question requires calculating the minimum clamp force needed to support a mold, given its dimensions, tonnage factor, and the capacity of the machine used. The second questions asks to calculate the percent change of the area of the gate, when the round gate is changed from 0.030 inch to 0.040 inch.

Answer

336.84 tons 77.79%

Answer for screen readers

336.84 tons 77.79%

Steps to Solve

- Calculate the area of the round part

The formula for the area of a circle is $A = \pi r^2$, where $r$ is the radius. The diameter is 6 inches, so the radius is half of that, which is 3 inches. Thus, area of the round part is:

$$ A_{part} = \pi (3 \text{ in})^2 = 9\pi \text{ in}^2$$

- Calculate the area of the hole

The diameter of the hole is 0.5 inches, so the radius is 0.25 inches. Thus, area of the hole is:

$$ A_{hole} = \pi (0.25 \text{ in})^2 = 0.0625\pi \text{ in}^2$$

- Calculate the net area of one part

The net area of one part is the area of the round part minus the area of the hole:

$$ A_{net} = A_{part} - A_{hole} = 9\pi \text{ in}^2 - 0.0625\pi \text{ in}^2 = 8.9375\pi \text{ in}^2 $$

- Calculate the total area for four cavities

Since there are four cavities, the total area is:

$$ A_{total} = 4 \times A_{net} = 4 \times 8.9375\pi \text{ in}^2 = 35.75\pi \text{ in}^2$$

- Calculate the minimum required clamp force

The tonnage factor is 3 tons per square inch. To find the minimum required clamp force, multiply the total area by the tonnage factor:

$$ F_{clamp} = A_{total} \times \text{tonnage factor} = 35.75\pi \text{ in}^2 \times 3 \frac{\text{tons}}{\text{in}^2} = 107.25\pi \text{ tons} \approx 336.84 \text{ tons} $$

- Calculate the initial area of the gate

The original diameter of the round gate is 0.030 inches, so the initial radius is 0.015 inches. Therefore, the initial area is:

$$A_1 = \pi r_1^2 = \pi (0.015 \text{ in})^2 = 0.000225\pi \text{ in}^2$$

- Calculate the final area of the gate

The final diameter of the round gate is 0.040 inches, so the final radius is 0.020 inches. Therefore, the final area is:

$$A_2 = \pi r_2^2 = \pi (0.020 \text{ in})^2 = 0.0004\pi \text{ in}^2$$

- Calculate the percent change of the area of the gate

The percent change is calculated as:

$$ \text{Percent Change} = \frac{A_2 - A_1}{A_1} \times 100% = \frac{0.0004\pi - 0.000225\pi}{0.000225\pi} \times 100% $$ $$ \text{Percent Change} = \frac{0.000175\pi}{0.000225\pi} \times 100% = \frac{0.000175}{0.000225} \times 100% \approx 77.78% $$ Rounding to two decimal places, the percent change is approximately 77.78%.

336.84 tons 77.79%

More Information

The clamp force must be less than the capacity of the machine used, 400 tons.

Tips

Null

AI-generated content may contain errors. Please verify critical information