Podcast

Questions and Answers

What is the primary use of flexible metal conduits?

What is the primary use of flexible metal conduits?

- To simplify installations in tight spaces with many bends. (correct)

- To support large conductor sizes in cellular metal raceways.

- For managing extensive wiring in open ceiling areas.

- For use exclusively in fire-resistant buildings.

Which type of raceway is specifically mentioned as being suitable for locations with corrosive liquids?

Which type of raceway is specifically mentioned as being suitable for locations with corrosive liquids?

- Cellular metal raceways

- Non-metallic conduit (PVC) (correct)

- Surface metal raceways

- Underfloor raceways

What distinguishes service entrance cable from other types of cables?

What distinguishes service entrance cable from other types of cables?

- It supports larger conductor sizes than 500,000 circular mils.

- It is not suitable for wet locations.

- It is specifically for service entrance applications. (correct)

- It is exclusively non-metallic sheathed cable.

Which wiring method is best for installing additional outlets in buildings where concealment of conductors is challenging?

Which wiring method is best for installing additional outlets in buildings where concealment of conductors is challenging?

Why are busways predominantly used in industrial plants?

Why are busways predominantly used in industrial plants?

What is a primary reason for running a green ground wire in PVC conduit?

What is a primary reason for running a green ground wire in PVC conduit?

Which type of conduit is best suited for areas requiring tight bends?

Which type of conduit is best suited for areas requiring tight bends?

What is a characteristic feature of Electrical Metallic Tubing (EMT)?

What is a characteristic feature of Electrical Metallic Tubing (EMT)?

For which scenarios is the use of Rigid metal conduit most appropriate?

For which scenarios is the use of Rigid metal conduit most appropriate?

What must be considered before installing electrical wiring systems?

What must be considered before installing electrical wiring systems?

Why is open wiring on insulators typically used?

Why is open wiring on insulators typically used?

What distinguishes Intermediate Metallic Conduit (IMC) from other types of conduit?

What distinguishes Intermediate Metallic Conduit (IMC) from other types of conduit?

What is a disadvantage of using rigid metal conduit?

What is a disadvantage of using rigid metal conduit?

What is the primary purpose of using conduit wiring?

What is the primary purpose of using conduit wiring?

Which type of conduit installation involves placing the conduit concealed within walls or roofs?

Which type of conduit installation involves placing the conduit concealed within walls or roofs?

Which material is commonly used for underground and wet location applications?

Which material is commonly used for underground and wet location applications?

What feature of strong conduit allows it to withstand heavy loads, such as being driven over?

What feature of strong conduit allows it to withstand heavy loads, such as being driven over?

How are PVC conduit fittings typically attached?

How are PVC conduit fittings typically attached?

What does the National Electrical Code require regarding conduit usage?

What does the National Electrical Code require regarding conduit usage?

What type of conduit installation is typically referred to as surface wiring?

What type of conduit installation is typically referred to as surface wiring?

Which statement is true regarding the installation of conduit wiring?

Which statement is true regarding the installation of conduit wiring?

Flashcards

Conduit Wiring

Conduit Wiring

A wiring system using tubes (pipes) for mechanical and fire protection of electrical conductors.

Conduit Types

Conduit Types

Conduit wiring systems come in surface (open) and recessed (concealed) installations.

PVC Conduit

PVC Conduit

A type of conduit commonly used in underground or wet locations due to its water resistance.

Surface Conduit Installation

Surface Conduit Installation

Signup and view all the flashcards

Concealed Conduit Installation

Concealed Conduit Installation

Signup and view all the flashcards

Wiring Safety

Wiring Safety

Signup and view all the flashcards

Conduit Materials

Conduit Materials

Signup and view all the flashcards

Wiring Considerations

Wiring Considerations

Signup and view all the flashcards

Concealed wiring

Concealed wiring

Signup and view all the flashcards

Flexible metal conduits

Flexible metal conduits

Signup and view all the flashcards

Underfloor raceways

Underfloor raceways

Signup and view all the flashcards

Cellular metal raceways

Cellular metal raceways

Signup and view all the flashcards

Wireways

Wireways

Signup and view all the flashcards

Electrical Metallic Tubing (EMT)

Electrical Metallic Tubing (EMT)

Signup and view all the flashcards

Intermediate Metallic Conduit (IMC)

Intermediate Metallic Conduit (IMC)

Signup and view all the flashcards

Rigid Metal Conduit

Rigid Metal Conduit

Signup and view all the flashcards

Open Wiring on Insulators

Open Wiring on Insulators

Signup and view all the flashcards

Why Ground Wires in PVC Conduit?

Why Ground Wires in PVC Conduit?

Signup and view all the flashcards

Electrical Wiring Installation Factors

Electrical Wiring Installation Factors

Signup and view all the flashcards

Importance of Proper Electrical Wiring

Importance of Proper Electrical Wiring

Signup and view all the flashcards

Study Notes

Wiring Regulations

- Electrical wiring demands expert attention for all building projects, directly impacting human safety and equipment handling.

- Wiring scope encompasses supply, installation, testing, and commissioning of conduits, accessories, wiring, switches, outlets, junction boxes, pull boxes, and connections.

Wiring Materials and Installation

- Electrical wiring needs expert attention, directly related to human safety and building utility/equipment safety.

- Scope includes supply, installation, testing, commissioning of all conduits, accessories, wiring, switches, socket outlets, spur outlets, junction boxes/pull boxes, GI pull wires, ceiling roses, and connections.

Conduit Wiring and Installation Methods

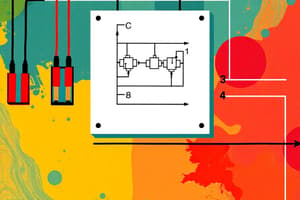

- Conduit wiring uses tubes (steel or PVC) for mechanical and fire protection of conductors.

- Conduit pipes can be installed on walls/roofs (using saddles/hooks) or concealed within walls/roofs/floors.

- Modern construction utilizes PVC or GI conduit, with installation types varying based on site requirements and specifications. These are surface/open and recessed/concealed.

Why Use Conduit Wiring

- When starting wiring projects, deciding on the right type is crucial.

- Some wiring has a sheath coating requiring only stapling to wall studs and joists.

- Conduit is a common choice.

Protecting Wires from Damage

- Conduits vary in strength (from fairly strong to extremely rigid) to prevent damage during installation and use.

- Choosing the correct conduit type is essential, satisfying project needs and complying with the National Electrical Code.

PVC Conduit

- Commonly used in underground and wet locations.

- Features PVC fittings, connectors, couplings, and elbows, easily attached with a cleaner and PVC glue.

- PVC is non-conductive, requiring proper grounding methods at connection points using a green ground wire.

Flexible Metal Conduit

- Ideal for areas requiring tight bends and close quarters (e.g., water heaters, can lights, attic vents).

- Typically used for installations with frequent bends and limited space.

Electrical Metallic Tubing (EMT)

- Lightweight, easily bent, used within walls.

- Easily damaged unlike IMC or RMC/RSC.

Intermediate Metallic Conduit (IMC)

- Thicker, galvanized conduit, making it suitable for outdoor installations, exposed walls (basements, garages), or areas prone to damage.

Rigid Metal Conduit

- Thickest and heaviest conduit, suitable for extreme conditions (e.g., under driveways, service feeder installations).

- More expensive, frequently used for service entrance piping due to its strength and durability that can withstand wind, falling branches, and storm damage.

Electrical Wiring Systems and Methods

- Electrical wiring installations must comply with regulations and standards.

- Incorrect installations can damage devices and result in reduced device lifespan.

- Factors like building construction type, ceiling/wall/floor construction, and installation requirements influence wiring choices.

Individual Conductor Systems

- Open wiring on insulators: Suitable for temporary wiring, offering protection through flexible mica tubing, porcelain tubing, and cleats, especially beneficial when making bends and connecting wires.

Concealed Wiring

- Concealed wiring resembles open wiring, but conductors are hidden within walls or ceilings.

Raceway Systems

- Flexible metal conduits: Used instead of rigid conduits when needing numerous bends.

- Underfloor raceways: Commonly found in fire-resistant buildings, provide an enclosed conduit system beneath the flooring.

- Cellular metal raceways: Used with cellular steel floors, preventing larger conductors from disrupting the system.

- Wireways: Offer convenient metal raceways for conductors up to 500,000 circular mils.

- Busways: Often used in industrial plants due to adaptability for future expansions and modifications of production lines.

- Surface metal raceways: Commonly used in buildings for additional outlets in areas where concealing conduits is more challenging using a metal molding.

Other Systems

- Non-metallic conduit (PVC): Suitable for industrial environments with corrosive liquids, simplifying conduit layouts when encountering obstructions.

- Cable assembly system:

- Service entrance cable: Armored or non-metallic sheathed cables for service entrance purposes only.

- Non-metallic waterproof wiring: Used in cold storage and wet locations where corrosive fumes and vapors are present.

- Non-metallic extensions: Used for adding additional outlets from existing ones.

- Underplaster extensions: Used to expand existing branch circuits by creating additional outlets.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.