Podcast

Questions and Answers

What is the primary reason for alloying elements such as chromium, molybdenum, nickel, and vanadium with cast iron in cylinder liner construction?

What is the primary reason for alloying elements such as chromium, molybdenum, nickel, and vanadium with cast iron in cylinder liner construction?

- To reduce the weight of the liner

- To increase the cost of the liner

- To improve the strength, wear resistance, and oil retention of the liner (correct)

- To improve the corrosion resistance of the liner

What is the purpose of hard chrome plating on some cylinder liners?

What is the purpose of hard chrome plating on some cylinder liners?

- To enhance the liner's corrosion resistance

- To improve the liner's thermal conductivity

- To reduce friction between the liner and piston

- To improve the liner's wear characteristics (correct)

What is the primary function of the liner flange in a dry liner design?

What is the primary function of the liner flange in a dry liner design?

- To provide a surface for the piston to ride on

- To form a combustion seal between the liner and the head gasket (correct)

- To facilitate heat transfer between the liner and engine coolant

- To provide additional support to the cylinder head

Why are cylinder liners not supported out of the block?

Why are cylinder liners not supported out of the block?

What is the consequence of a slight crack in a cylinder liner?

What is the consequence of a slight crack in a cylinder liner?

What type of cylinder liner has no contact with engine coolant?

What type of cylinder liner has no contact with engine coolant?

What is the primary purpose of the mid-stop design in liners?

What is the primary purpose of the mid-stop design in liners?

What is the primary method of heat removal in an air cooled cylinder liner?

What is the primary method of heat removal in an air cooled cylinder liner?

What is the function of the gasket clamped between the cylinder head and the liner in an air cooled engine?

What is the function of the gasket clamped between the cylinder head and the liner in an air cooled engine?

What is the primary difference between dry and wet liners?

What is the primary difference between dry and wet liners?

Why are air cooled diesel engines less common than liquid cooled designs?

Why are air cooled diesel engines less common than liquid cooled designs?

What is the purpose of the studs that pass through the liner and cylinder head in an air cooled engine?

What is the purpose of the studs that pass through the liner and cylinder head in an air cooled engine?

What is the purpose of the relief cut under the flange of a cylinder liner?

What is the purpose of the relief cut under the flange of a cylinder liner?

What is the main difference between a dry liner and a wet liner?

What is the main difference between a dry liner and a wet liner?

What is the purpose of the bead on top of the flange of a wet liner?

What is the purpose of the bead on top of the flange of a wet liner?

What is the purpose of the seal rings located between the lower end of the liner and the block?

What is the purpose of the seal rings located between the lower end of the liner and the block?

What is the advantage of the mid-stop design of wet liners?

What is the advantage of the mid-stop design of wet liners?

Why is the correct fit between the liner and the block important?

Why is the correct fit between the liner and the block important?

What is the purpose of the firewall in a cylinder liner?

What is the purpose of the firewall in a cylinder liner?

What is the difference in construction between a dry liner and a wet liner?

What is the difference in construction between a dry liner and a wet liner?

What is the purpose of the flange at the top of the liner?

What is the purpose of the flange at the top of the liner?

What is the advantage of using a dry liner?

What is the advantage of using a dry liner?

What is the primary material used in the construction of heavy-duty diesel engine cylinder blocks?

What is the primary material used in the construction of heavy-duty diesel engine cylinder blocks?

What is the benefit of using aluminum in some components of the cylinder block assembly?

What is the benefit of using aluminum in some components of the cylinder block assembly?

What is the oldest process used to manufacture cylinder blocks?

What is the oldest process used to manufacture cylinder blocks?

What is the primary difference between cast iron and aluminum in terms of strength?

What is the primary difference between cast iron and aluminum in terms of strength?

What is the reason for alloying elements such as chromium, nickel, phosphorous, and silicon with cast iron?

What is the reason for alloying elements such as chromium, nickel, phosphorous, and silicon with cast iron?

What is the primary advantage of using aluminum over cast iron in some engine components?

What is the primary advantage of using aluminum over cast iron in some engine components?

What is the primary purpose of using a disposable core in the sand casting process?

What is the primary purpose of using a disposable core in the sand casting process?

What is the main advantage of using enbloc designs with integral cylinders?

What is the main advantage of using enbloc designs with integral cylinders?

What is the primary reason for using modular or sectional construction in large industrial or stationary engine blocks?

What is the primary reason for using modular or sectional construction in large industrial or stationary engine blocks?

What is the advantage of using a two-piece block construction in large displacement engines?

What is the advantage of using a two-piece block construction in large displacement engines?

What is the primary purpose of using a one-piece rigid assembly in enbloc designs?

What is the primary purpose of using a one-piece rigid assembly in enbloc designs?

What is the primary difference between enbloc and modular or sectional engine blocks?

What is the primary difference between enbloc and modular or sectional engine blocks?

What is the primary purpose of using removable liners in enbloc designs?

What is the primary purpose of using removable liners in enbloc designs?

What is the primary advantage of using a three-piece block construction in large displacement engines?

What is the primary advantage of using a three-piece block construction in large displacement engines?

What is the primary purpose of using a V6 block section in a V12 engine?

What is the primary purpose of using a V6 block section in a V12 engine?

What is the primary reason for using cylinder blocks in engine construction?

What is the primary reason for using cylinder blocks in engine construction?

سیلنڈر بلاک کی تعمیر میں دو عام مواد کون سے ہیں؟

سیلنڈر بلاک کی تعمیر میں دو عام مواد کون سے ہیں؟

کاسٹ آئرن کی特یت میں کون سے عناصر شامل ہیں؟

کاسٹ آئرن کی特یت میں کون سے عناصر شامل ہیں؟

سیلنڈر بلاک کی تعمیر میں کون سا طریقہ古ڑھکت ہے؟

سیلنڈر بلاک کی تعمیر میں کون سا طریقہ古ڑھکت ہے؟

الومینیم کی کون سی خصوصیت کاسٹ آئرن سے زیادہ ہے؟

الومینیم کی کون سی خصوصیت کاسٹ آئرن سے زیادہ ہے؟

کاسٹ آئرن سیلنڈر بلاک کی کون سی خصوصیت الومینیم سے زیادہ ہے؟

کاسٹ آئرن سیلنڈر بلاک کی کون سی خصوصیت الومینیم سے زیادہ ہے؟

الومینیم کی کون سی خصوصیت کاسٹ آئرن سے کم ہے؟

الومینیم کی کون سی خصوصیت کاسٹ آئرن سے کم ہے؟

انجن بلوک کی تیاری کے لیے کس قسم کے مال_dl کو استعمال کیا جاتا ہے؟

انجن بلوک کی تیاری کے لیے کس قسم کے مال_dl کو استعمال کیا جاتا ہے؟

ڈیزل انجن میں سیلنڈر بلوک کی.Design کیا ہے؟

ڈیزل انجن میں سیلنڈر بلوک کی.Design کیا ہے؟

انجن کی تعمیر میں کس قسم کے بلوک استعمال کیے جاتے ہیں؟

انجن کی تعمیر میں کس قسم کے بلوک استعمال کیے جاتے ہیں؟

ساند کاسٹنگ کے عمل میں کس چیز کو استعمال کیا جاتا ہے؟

ساند کاسٹنگ کے عمل میں کس چیز کو استعمال کیا جاتا ہے؟

این بلوک ڈیزاین میں سیلنڈر کی تعمیر کی جاتی ہے؟

این بلوک ڈیزاین میں سیلنڈر کی تعمیر کی جاتی ہے؟

مڈولر بلوک کی تعمیر میں کیا استعمال کیا جاتا ہے؟

مڈولر بلوک کی تعمیر میں کیا استعمال کیا جاتا ہے؟

این بلوک ڈیزاین میں کیوں استعمال کی جاتی ہے؟

این بلوک ڈیزاین میں کیوں استعمال کی جاتی ہے؟

ساند کاسٹنگ کے عمل میں کس کا استعمال کیا جاتا ہے؟

ساند کاسٹنگ کے عمل میں کس کا استعمال کیا جاتا ہے؟

مڈولر بلوک کی تعمیر میں کیوں استعمال کی جاتی ہے؟

مڈولر بلوک کی تعمیر میں کیوں استعمال کی جاتی ہے؟

این بلوک اور مڈولر بلوک میں کیا فرق ہے؟

این بلوک اور مڈولر بلوک میں کیا فرق ہے؟

Flashcards are hidden until you start studying

Study Notes

Cylinder Block Construction and Materials

- Two primary materials for cylinder blocks: cast iron and aluminum.

- Alloy cast iron is predominant in heavy-duty diesel engine blocks, mixed with elements like chromium, nickel, phosphorous, and silicon for enhanced properties.

- Cast iron offers strength, rigidity, and durability against the internal forces of diesel engines but is heavier than aluminum.

- Aluminum is favored for gasoline engine blocks, providing lightweight and high heat transfer but not used for heavy-duty diesel blocks.

- Aluminum is used in components like front gear covers and oil pans.

Manufacturing Processes

- Cylinder blocks are manufactured through casting and fabrication processes.

- Sand casting involves pouring molten metal into sand molds, forming cavities for cylinder bores and coolant passages.

- Fabrication includes assembling large engines from bolted or welded sections, necessary for impractically large one-piece castings.

Types of Cylinder Blocks

- Two types of cylinder blocks: enbloc and modular (sectional).

Enbloc Design

- Cylinders and crankcase form a single rigid assembly; used widely in mobile and some stationary engines.

- Enbloc with integral cylinders offers lower manufacturing costs but requires machining for repairs on worn cylinder bores.

- Enbloc with removable liners allows maintenance without machining, using replaceable parts.

Modular/Sectional Design

- Common in large industrial or stationary engines, manufactured in sections for onsite assembly.

- Less rigid but manageable for manufacturing; consists of upper assemblies for camshafts and cylinders, and lower assemblies for crankshafts and crankcases.

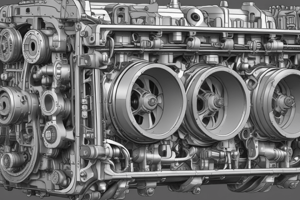

Cylinder Liners Construction

- Cylinder liners are primarily made from alloy cast iron mixed with elements like chromium, molybdenum, nickel, and vanadium for strength and wear resistance.

- Liners are often induction hardened and can be treated chemically or plated for durability.

Types of Cylinder Liners

- Three common styles: dry liners, wet liners, air-cooled liners.

Dry Liner

- Replaceable sleeve that does not contact coolant, secured by the cylinder head and block counterbore.

- Allows for effective combustion sealing and cooling at the upper section, often designed for various shapes and sizes.

Wet Liner

- In direct contact with coolant for temperature regulation, equipped with seals to prevent coolant leakage into the crankcase.

- Must have heavier construction due to lack of full-length support from the block.

Air-Cooled Liner

- Features cooling fins to dissipate heat via airflow, utilized in situations where liquid cooling is less common.

- Installation involves securing the liner with studs to maintain moisture and combustion seal integrity.

Benefits and Challenges of Cylinder Liners

- Proper fit between liners and blocks is crucial for heat transfer and engine performance.

- Damage to liners can lead to severe engine failures, emphasizing the need for careful handling during manufacturing and installation.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.