Podcast

Questions and Answers

What is the primary purpose of the UHT process?

What is the primary purpose of the UHT process?

- To extend the shelf life of food products (correct)

- To change the color of food products

- To increase the nutritional value of food

- To enhance the flavor of dairy products

What is the typical temperature required to kill spores in milk during UHT processing?

What is the typical temperature required to kill spores in milk during UHT processing?

- 150°C (302°F)

- 100°C (212°F)

- 180°C (356°F)

- 135°C (275°F) (correct)

What is the typical holding time at sterilization temperature during UHT processing?

What is the typical holding time at sterilization temperature during UHT processing?

- 1-2 seconds (correct)

- 1-2 minutes

- 5-10 minutes

- 15-30 seconds

What is the primary difference between UHT and HTST pasteurization?

What is the primary difference between UHT and HTST pasteurization?

What is a common side effect of high heat during the UHT process?

What is a common side effect of high heat during the UHT process?

What is the typical shelf life of UHT milk?

What is the typical shelf life of UHT milk?

What is an alternative position for homogenisation in the UHT process?

What is an alternative position for homogenisation in the UHT process?

What is the most common UHT product?

What is the most common UHT product?

What is the main advantage of infusion direct heating method?

What is the main advantage of infusion direct heating method?

What is the purpose of flash cooling in vacuum chamber in direct heating?

What is the purpose of flash cooling in vacuum chamber in direct heating?

What is the main limitation of direct heating injection method?

What is the main limitation of direct heating injection method?

What is the principle of membrane processing?

What is the principle of membrane processing?

What is the main advantage of indirect heating systems?

What is the main advantage of indirect heating systems?

What is the purpose of membrane processing in whey?

What is the purpose of membrane processing in whey?

What is the main difference between concentrated and dried dairy products?

What is the main difference between concentrated and dried dairy products?

What is the water content of fluid milk?

What is the water content of fluid milk?

What happens to the skim milk during separation?

What happens to the skim milk during separation?

How is the desired fat content achieved during direct standardization?

How is the desired fat content achieved during direct standardization?

What was the original application of the pasteurization process?

What was the original application of the pasteurization process?

What is the primary purpose of milk pasteurization from a public health aspect?

What is the primary purpose of milk pasteurization from a public health aspect?

What is the minimum temperature required for pasteurization of milk for at least 30 minutes?

What is the minimum temperature required for pasteurization of milk for at least 30 minutes?

What is used to determine if milk has been pasteurized?

What is used to determine if milk has been pasteurized?

What is an additional benefit of pasteurization besides making milk safe for consumption?

What is an additional benefit of pasteurization besides making milk safe for consumption?

How often can the shelf life of pasteurized milk be extended?

How often can the shelf life of pasteurized milk be extended?

Flashcards are hidden until you start studying

Study Notes

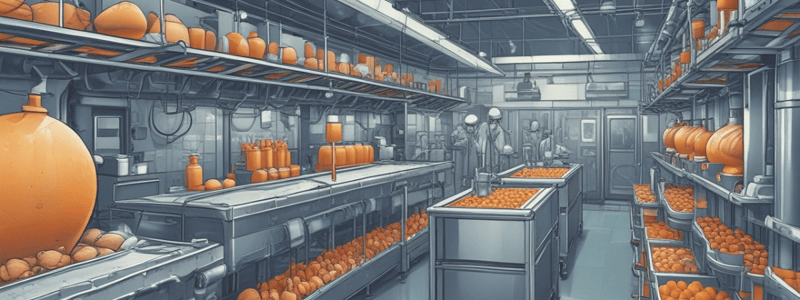

UHT Process

- The UHT process involves preheating, homogenization, heating to sterilization temperature, holding, initial cooling, homogenization, final cooling, and aseptic packaging.

- The sterilization temperature is above 135°C (275°F) for an extremely short period, around 1–2 seconds.

UHT Processing

- UHT stands for ultra-high temperature processing, ultra-heat treatment, or ultra-pasteurization.

- It is used for milk, fruit juices, cream, soy milk, yogurt, wine, soups, and stews.

- UHT milk was invented in the 1960s and became available in the 1970s.

- High heat can cause Maillard browning and change the taste and smell of dairy products.

- UHT milk has a typical shelf life of six to nine months, until opened.

UHT Methods

- There are two principal methods of UHT treatment: direct heating and indirect heating.

Direct Heating Systems

- There are two methods of direct heating: injection and infusion.

- Injection involves high-pressure steam injection into pre-heated liquid, rapid heating, and flash cooling.

- Infusion involves pumping food into a chamber of high-pressure steam, instantaneous heating, and rapid cooling.

- Infusion has several advantages, including no localized overheating or burn-on, and suitability for low and higher viscosity products.

Indirect Heating Systems

- The heating medium and product are not in direct contact, but separated by equipment contact surfaces.

- Several types of heat exchangers are applicable, including plate, tubular, and scraped surface.

Membrane Processing of Milk

- Membrane processing is a technique that permits concentration and separation without heat.

- It separates particles based on their molecular size and shape using pressure and specially designed semi-permeable membranes.

- It can be used for protein separation in whey, milk concentration before cheesemaking, and other applications.

Concentrated and Dried Dairy Products

- Fluid milk contains approximately 88% water.

- Concentrated milk products are obtained through partial water removal.

- Dried dairy products have even greater amounts of water removed to usually less than 4%.

Standardization

- The streams of skim and cream after separation must be recombined to a specified fat content.

- This can be done by adjusting the throttling valve of the cream outlet or through direct standardization.

Pasteurization

- The process of pasteurization was named after Louis Pasteur.

- It involves heating every particle of milk or milk product to a specific temperature for a specified period.

- The purpose is to make milk and milk products safe for human consumption and to improve their keeping quality.

- Pasteurization can destroy pathogens, undesirable enzymes, and spoilage bacteria.

- Typical pasteurization regulations for milk include heating to 63°C for at least 30 minutes or 72°C for at least 16 seconds.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.