Podcast

Questions and Answers

What is a distinguishing feature of an Omniversal milling machine?

What is a distinguishing feature of an Omniversal milling machine?

- It has a circular workpiece supporting table

- It has a single-spindle head

- The table rotates about a vertical axis

- The table can be tilted in a vertical plane (correct)

What movement restriction is a characteristic of Manufacturing Type/Fixed Bed Type milling machines?

What movement restriction is a characteristic of Manufacturing Type/Fixed Bed Type milling machines?

- Restricted vertical movement of the spindle head

- Table mounted directly on the ways of a fixed bed (correct)

- Restricted horizontal movement of the cutter

- Single-spindle head design

What is the distinguishing feature of a Drum milling machine?

What is the distinguishing feature of a Drum milling machine?

- It has a spindle for rotating the cutter

- It has a circular workpiece supporting table (correct)

- It rotates about a vertical axis

- It has a single-spindle head

In what way does a Special Type milling machine differ from other types?

In what way does a Special Type milling machine differ from other types?

What distinguishes a Planer Type milling machine from others?

What distinguishes a Planer Type milling machine from others?

Which milling machine allows continuous loading and unloading of workpieces by the operator while in progress?

Which milling machine allows continuous loading and unloading of workpieces by the operator while in progress?

Which milling operation is performed by using a face milling cutter rotated about an axis perpendicular to the work surface?

Which milling operation is performed by using a face milling cutter rotated about an axis perpendicular to the work surface?

What is the main purpose of angular milling in milling operations?

What is the main purpose of angular milling in milling operations?

What type of milling operation involves machining several surfaces of a workpiece simultaneously by feeding against multiple cutters?

What type of milling operation involves machining several surfaces of a workpiece simultaneously by feeding against multiple cutters?

Which milling operation is used to produce irregular contours using form cutters for shapes like convex, concave, or other shapes?

Which milling operation is used to produce irregular contours using form cutters for shapes like convex, concave, or other shapes?

In which milling operation are keyways, grooves, and slots typically machined?

In which milling operation are keyways, grooves, and slots typically machined?

Which type of milling operation is used for reproducing an outline of a template or a complex shape?

Which type of milling operation is used for reproducing an outline of a template or a complex shape?

What type of milling machine is characterized by having the table mounted on the knee-casting, which is in turn mounted on the vertical slides of the main column?

What type of milling machine is characterized by having the table mounted on the knee-casting, which is in turn mounted on the vertical slides of the main column?

In which type of milling machine is the spindle position vertical or perpendicular to the table?

In which type of milling machine is the spindle position vertical or perpendicular to the table?

What is the characteristic feature of a hand milling machine?

What is the characteristic feature of a hand milling machine?

Which type of milling machine is known for being small in size and suitable for light and simple milling operations?

Which type of milling machine is known for being small in size and suitable for light and simple milling operations?

What role does the overhanging arm play in a milling machine?

What role does the overhanging arm play in a milling machine?

Which type of milling machine would be most suitable for machining grooves, slots, and flat surfaces?

Which type of milling machine would be most suitable for machining grooves, slots, and flat surfaces?

Flashcards

Universal Milling Machine

Universal Milling Machine

Adapts to many milling tasks; table swivels up to 45 degrees on either side.

Omniversal Milling Machine

Omniversal Milling Machine

Has four movements like the universal type, plus vertical tilting capability.

Manufacturing Type Milling Machine

Manufacturing Type Milling Machine

Large, rigid machine with the table directly mounted on a fixed bed.

Simplex, Duplex, Triplex Milling Machines

Simplex, Duplex, Triplex Milling Machines

Signup and view all the flashcards

Planer Type Milling Machine

Planer Type Milling Machine

Signup and view all the flashcards

Special Type Milling Machine

Special Type Milling Machine

Signup and view all the flashcards

Plain Milling

Plain Milling

Signup and view all the flashcards

Face Milling

Face Milling

Signup and view all the flashcards

Side Milling

Side Milling

Signup and view all the flashcards

Straddle Milling

Straddle Milling

Signup and view all the flashcards

Angular Milling

Angular Milling

Signup and view all the flashcards

Gang Milling

Gang Milling

Signup and view all the flashcards

Form Milling

Form Milling

Signup and view all the flashcards

Profile Milling

Profile Milling

Signup and view all the flashcards

End Milling

End Milling

Signup and view all the flashcards

Spindle

Spindle

Signup and view all the flashcards

Overhanging Arm

Overhanging Arm

Signup and view all the flashcards

Front Brace

Front Brace

Signup and view all the flashcards

Study Notes

Types of Milling Machines

- Universal milling machines can be adapted to a wide range of milling operations and their table can be swiveled to any angle up to 45-degrees on either side.

- Omniversal milling machines have four movements of the universal milling machine and can be tilted in a vertical plane.

- Manufacturing type/fixed bed type milling machines are large, heavy, and rigid in construction, with the table mounted directly on the ways of a fixed bed.

- Simplex, duplex, and triplex milling machines have one, two, and three spindle heads respectively.

- Planer type milling machines are used for heavy-duty work and have spindle heads adjustable in the vertical and transverse direction.

- Special type milling machines have a spindle for rotating the cutter and provision for moving the tool or the work in different directions.

- Rotary table milling machines have a circular table that rotates about a vertical axis, allowing for continuous loading and unloading of workpieces.

- Drum milling machines have a workpiece supporting table that rotates in the horizontal axis.

- Profile milling machines duplicate the full size of the template attached to the machine.

- Planetary milling machines have a workpiece held stationary while the revolving cutter.

- Tracer control pentagraph milling machines allow the size of the workpiece reproduced to be smaller than, equal to or greater than the size of a template.

Milling Operations

- Plain milling produces plain, flat, horizontal surfaces (also known as slab milling).

- Face milling is the simplest milling operation performed by a face milling cutter rotated about an axis perpendicular to the work surface.

- Side milling produces a flat vertical surface on both sides of a workpiece using two side milling cutters.

- Straddle milling is used to design a square or hexagonal surface.

- Angular milling produces an angular surface on a workpiece at right angles of the axis of the spindle.

- Gang milling machines several surfaces of a workpiece simultaneously by feeding the table against a number of cutters.

- Form milling produces an irregular contour by using form cutters.

- Profile milling reproduces an outline of a template or complex shape.

Other Milling Operations

- End milling is a widely used milling operation.

- Saw milling, keyways, groove, and slot milling are other operations.

- Gear milling, helical milling, cam milling, thread milling, and other operations are also performed.

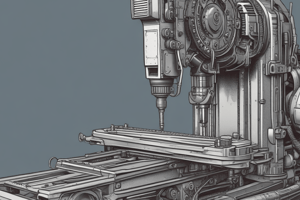

Milling Machine Components

- The base of a milling machine carries the column at its one end.

- The column is the main supporting frame.

- The knee is a fixed gray iron casting that slides up and down on the vertical ways of the column.

- The saddle is placed on top of the knee and slides on guide ways set exactly at 90 degrees to the column face.

- The table rests on guideways on the saddle and travels longitudinally.

- The spindle is located in the upper part of the column and receives power from the motor through belts, gears, and clutches.

- The overhanging arm acts as a support for the arbor.

- The front brace provides rigidly to the arbor and the knee.

- The arbor is an extension of the machine spindle on which milling cutters are securely mounted and rotated.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.