Podcast

Questions and Answers

What can cause excessive blade creep?

What can cause excessive blade creep?

- Severe over-speeding or high temperature (correct)

- Normal operating conditions

- Turbine disc growth

- Routine maintenance checks

When are blade creep checks typically performed?

When are blade creep checks typically performed?

- After every flight

- Only after over-temperature or over-speeding

- During routine maintenance checks

- At intervals laid down in the maintenance manual or when operated outside working limits (correct)

What is the most accurate method of carrying out a creep check?

What is the most accurate method of carrying out a creep check?

- Inspecting the turbine disc for growth

- Measuring the distance between the turbine blade tip and the shroud ring

- Measuring each blade individually (correct)

- Checking the turbine shroud for warpage

Why is measuring each blade individually a less convenient method of creep check?

Why is measuring each blade individually a less convenient method of creep check?

What is the purpose of measuring the distance between the turbine blade tip and the shroud ring?

What is the purpose of measuring the distance between the turbine blade tip and the shroud ring?

What happens if the measurements obtained during a creep check are out of tolerance?

What happens if the measurements obtained during a creep check are out of tolerance?

Why is measuring the distance between the turbine blade tip and the shroud ring less accurate than measuring each blade individually?

Why is measuring the distance between the turbine blade tip and the shroud ring less accurate than measuring each blade individually?

What is the purpose of blade creep checks?

What is the purpose of blade creep checks?

What can be affected by turbine disc growth or turbine shroud warpage?

What can be affected by turbine disc growth or turbine shroud warpage?

Why are blade creep checks performed after an engine is operated outside its working limits?

Why are blade creep checks performed after an engine is operated outside its working limits?

Flashcards

Turbine Casing Material

Turbine Casing Material

Typically made from nickel-based alloys like Inconel.

Turbine Casing Cooling

Turbine Casing Cooling

Air passages control thermal expansion, improving efficiency.

Turbine Stator Function

Turbine Stator Function

Directs hot gases onto turbine blades, increasing efficiency.

Nozzle Guide Vane (NGV) Location

Nozzle Guide Vane (NGV) Location

Signup and view all the flashcards

Turbine Power Generation

Turbine Power Generation

Signup and view all the flashcards

Radial Inflow Turbine Use

Radial Inflow Turbine Use

Signup and view all the flashcards

Turbine Blade Material

Turbine Blade Material

Signup and view all the flashcards

Creep Check Purpose

Creep Check Purpose

Signup and view all the flashcards

Turbine Sealing Methods

Turbine Sealing Methods

Signup and view all the flashcards

Power Extraction in Turbines

Power Extraction in Turbines

Signup and view all the flashcards

Study Notes

Turbine Casing

- Turbine casings are typically made from nickel-based alloys such as Inconel.

- The perimeter of some turbine cases is encircled by passages that route cooling air to control thermal expansion, decreasing the clearance between the case and the turbine blades, making the turbine section more efficient.

Turbine Stator

- A stator element is known as a turbine inlet nozzle, nozzle guide vane (NGV), or nozzle diaphragm.

- Nozzle guide vanes are located directly aft of the combustion section and immediately forward of the turbine wheel.

- They are exposed to the highest temperatures in a gas turbine engine.

- The design of NGVs and turbine blades is based on aerodynamic considerations, with a basic aerofoil shape.

- The purpose of NGVs is to direct the combustion gases onto the turbine blades at the optimum angle of attack for efficient operation and to convert pressure energy into increased velocity of the gases flowing onto the turbine blades.

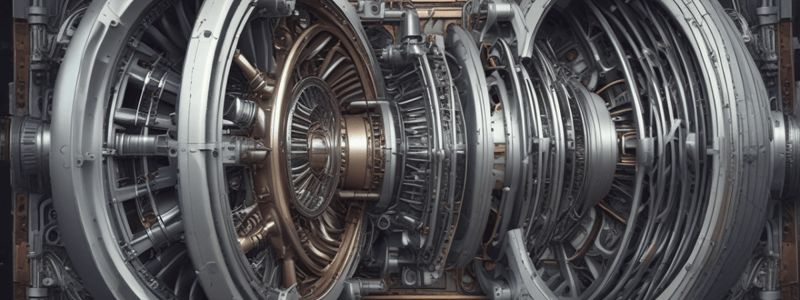

Turbine Section

- The turbine has the task of providing power to drive the compressor and accessories.

- It also provides shaft power for a propeller or rotor.

- The turbine extracts energy from the hot gases released from the combustion system and expands them to a lower pressure and temperature.

- Energy is extracted by passing the airflow over a set of aerofoil-shaped blades.

- High stresses are involved in this process, and turbine blade tips may rotate at speeds up to 1500 ft/s.

Radial Inflow Turbine

- Radial inflow turbines are sometimes used in ancillary equipment such as gas turbine compressors, Auxiliary Power Units (APUs), air turbine motors (ATMs), and some types of turbo superchargers.

- The design and construction of the turbine center on a disc having radially disposed vanes machined into its face.

- The main difference is the fitting of a set of vanes to the rear face of the turbine wheel, known as exducer vanes, which increase the length of the turbine vanes and increase the efficiency of the turbine.

Turbine Blades

- Most blades are precision cast and finished by grinding to the desired shape.

- Materials used have high temperature strength under centrifugal loads and are highly corrosion-resistant.

- Most turbine blades are cast as a single crystal, which gives them better strength and heat properties.

- The latest technology is producing turbine blades and vanes by 3D printing, which can be a combination of materials mixed together, making them lighter and capable of handling more heat.

Turbine Sealing Methods

- The most common method of sealing turbines is by an abradable shroud ring and knife edge tips.

- The shrouds are small segments at the tips of the blades to prevent leakage across the tips.

- The knife edge tips rotate within an abradable lining.

- When shrouded tips are not used, a snug fit between the tips and the turbine casing is ensured by either abradable blade tips or an abradable lining fitted to the case.

Power Extraction

- As the high-velocity gases pass through the turbine nozzle and impact the turbine blades, the turbine wheel rotates.

- In some engines, a single turbine wheel cannot absorb sufficient energy from the exhaust gas to drive the compressor and accessories.

- Many engines use multiple turbine stages, each stage consisting of a turbine nozzle and wheel.

Creep Checks

- Turbine checks are required at intervals laid down in the maintenance manual or when an engine is operated outside its working limits.

- There are two methods of carrying out a creep check: measuring each blade individually or measuring the distance between the turbine blade tip and the shroud ring.

- Measuring each blade individually is the most accurate method, but it requires the turbine assembly to be removed from the engine.

- Measuring the distance from the tip of the turbine blade to the shroud ring is a more convenient and practical method of ascertaining the turbine condition at short notice.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.