Podcast

Questions and Answers

What is the primary difference between a pipe and a tube?

What is the primary difference between a pipe and a tube?

- Outer diameter

- Cross-sectional shape

- Open-ended vs. closed (correct)

- Material used

What is the wall thickness of a tubular element?

What is the wall thickness of a tubular element?

- The material used to make the tube

- The inner diameter of the tube

- The outer diameter of the tube

- The difference between the OD and ID (correct)

What is a common application of tubular elements?

What is a common application of tubular elements?

- Aerospace engineering

- Fluid flow (correct)

- Medical devices

- Electrical insulation

Which manufacturing process is used to join tubes or pipes?

Which manufacturing process is used to join tubes or pipes?

What is the outer diameter of a tubular element?

What is the outer diameter of a tubular element?

What is a characteristic of tubular elements?

What is a characteristic of tubular elements?

What is a common material used to make tubular elements?

What is a common material used to make tubular elements?

What is the primary purpose of tubes in heat transfer applications?

What is the primary purpose of tubes in heat transfer applications?

Which process is used to cut, drill, and shape tubular elements?

Which process is used to cut, drill, and shape tubular elements?

What is a benefit of using tubular elements in structural applications?

What is a benefit of using tubular elements in structural applications?

Study Notes

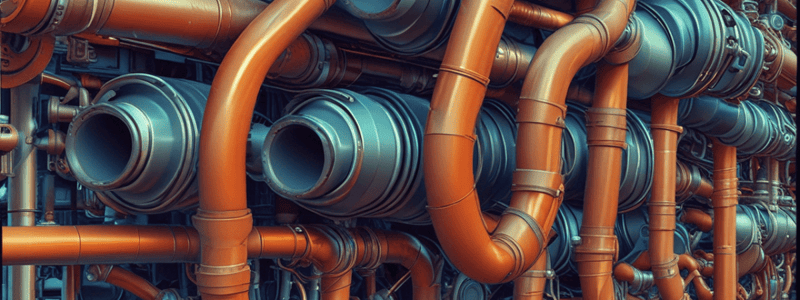

Types of Tubular Elements

- Pipes: Closed tubes with a circular cross-section, used for fluid flow, heat transfer, and structural applications.

- Tubes: Open-ended tubes with a circular or non-circular cross-section, used for structural, thermal, or electrical applications.

Characteristics of Tubular Elements

- Outer diameter (OD): The external diameter of the tube or pipe.

- Inner diameter (ID): The internal diameter of the tube or pipe.

- Wall thickness: The difference between the OD and ID, affecting strength, weight, and cost.

- Material: Tubular elements can be made from various materials, such as metals (e.g., steel, aluminum), plastics, or composites.

Applications of Tubular Elements

- Fluid flow: Pipes are used for transporting fluids, gases, or slurries in various industries (e.g., oil, gas, water, chemical).

- Structural: Tubular elements are used in construction, furniture, and machinery due to their high strength-to-weight ratio.

- Heat transfer: Tubes are used in heat exchangers, boilers, and condensers for efficient heat transfer.

- Electrical: Tubular elements are used as conductors, insulators, or shielding in electrical applications.

Manufacturing Processes for Tubular Elements

- Welding: Joining tubes or pipes through various welding techniques (e.g., arc, laser, resistance).

- Machining: Cutting, drilling, and shaping tubular elements to precise dimensions.

- Forming: Bending, drawing, or extruding tubes or pipes to desired shapes and sizes.

- Coating: Applying protective coatings or linings to enhance corrosion resistance or durability.

Types of Tubular Elements

- Pipes are closed tubes with a circular cross-section, used for fluid flow, heat transfer, and structural applications.

- Tubes are open-ended tubes with a circular or non-circular cross-section, used for structural, thermal, or electrical applications.

Characteristics of Tubular Elements

- Outer diameter (OD) is the external diameter of the tube or pipe.

- Inner diameter (ID) is the internal diameter of the tube or pipe.

- Wall thickness is the difference between the OD and ID, affecting strength, weight, and cost.

- Tubular elements can be made from various materials, such as metals (e.g., steel, aluminum), plastics, or composites.

Applications of Tubular Elements

- Pipes are used for transporting fluids, gases, or slurries in various industries (e.g., oil, gas, water, chemical).

- Tubular elements are used in construction, furniture, and machinery due to their high strength-to-weight ratio.

- Tubes are used in heat exchangers, boilers, and condensers for efficient heat transfer.

- Tubular elements are used as conductors, insulators, or shielding in electrical applications.

Manufacturing Processes for Tubular Elements

- Welding involves joining tubes or pipes through various welding techniques (e.g., arc, laser, resistance).

- Machining involves cutting, drilling, and shaping tubular elements to precise dimensions.

- Forming involves bending, drawing, or extruding tubes or pipes to desired shapes and sizes.

- Coating involves applying protective coatings or linings to enhance corrosion resistance or durability.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Learn about the different types of tubular elements, including pipes and tubes, and their characteristics such as outer diameter, inner diameter, and wall thickness.