Podcast

Questions and Answers

Textile manufacturing begins with the cultivation of natural fibers.

Textile manufacturing begins with the cultivation of natural fibers.

True (A)

Fabric can only be made by weaving or knitting process.

Fabric can only be made by weaving or knitting process.

False (B)

Wet processing involves dyeing and finishing the fabrics.

Wet processing involves dyeing and finishing the fabrics.

True (A)

The sizing process involves adding size material to the yarns in woven fabrics.

The sizing process involves adding size material to the yarns in woven fabrics.

Bleaching makes the fibers less absorbent and darker in color.

Bleaching makes the fibers less absorbent and darker in color.

Non-woven processes such as braiding and felting are used in the production of most fabrics

Non-woven processes such as braiding and felting are used in the production of most fabrics

The process of stable yarn manufacturing includes opening, cleaning, blending, mixing, cutting, drawing, roving, and spinning

The process of stable yarn manufacturing includes opening, cleaning, blending, mixing, cutting, drawing, roving, and spinning

Dyeing is the main process where white or gray fabric becomes decorated by different colors

Dyeing is the main process where white or gray fabric becomes decorated by different colors

The wet processing of fabric may involve mechanical and chemical processes to improve the acceptability of the product

The wet processing of fabric may involve mechanical and chemical processes to improve the acceptability of the product

The sizing process involves adding size material to the yarns in woven fabrics

The sizing process involves adding size material to the yarns in woven fabrics

Flashcards are hidden until you start studying

Study Notes

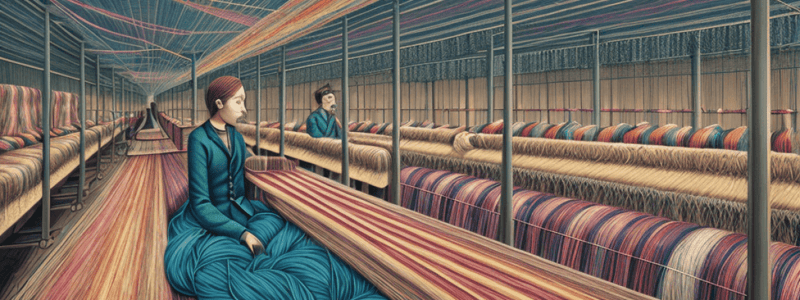

Textile Manufacturing Overview

- Begins with the cultivation of natural fibers, essential for fabric production.

- Fabric formation occurs through two primary processes: weaving and knitting.

Wet Processing

- Involves dyeing and finishing processes to enhance fabric quality.

- Dyeing transforms white or gray fabric into vibrant colors, improving aesthetic appeal.

- Can include both mechanical and chemical methods to increase product viability.

Sizing Process

- Essential in woven fabrics, where size materials are added to yarns for strength and durability.

- Repeated mention highlights its importance in textile manufacturing.

Bleaching and Non-Woven Processes

- Bleaching reduces fiber absorbency and darkens colors, playing a crucial role in fabric treatment.

- Non-woven techniques such as braiding and felting contribute to the creation of various types of fabrics.

Stable Yarn Manufacturing

- Comprises several sequential steps:

- Opening: Separating fibers for processing.

- Cleaning: Removing impurities from fibers.

- Blending and Mixing: Combining different fiber types for desired characteristics.

- Cutting, Drawing, Roving, and Spinning: Processes that transform raw fibers into usable yarns.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.