Podcast

Questions and Answers

What is the primary purpose of a Process Flow Diagram (PFD)?

What is the primary purpose of a Process Flow Diagram (PFD)?

- To provide a detailed layout of equipment

- To display the electrical connections of a system

- To illustrate the general arrangement of a plant

- To show the relationship between different components (correct)

What are the five major areas or parts of a standard plant diagram?

What are the five major areas or parts of a standard plant diagram?

- Title Block, Grid System, Revision Block, Notes, and Engineering Diagram (correct)

- Title Block, Grid System, Revision Block, Engineering Diagram, and Schematics

- Title Block, Revision Block, Notes, Legends, and Electrical Diagram

- Grid System, Revision Block, Notes, Engineering Diagram, and Equipment Diagram

What is typically located in the title block of a diagram?

What is typically located in the title block of a diagram?

- The engineering diagram and notes

- The electrical connections and schematics

- The diagram title, diagram number, site location, and diagram owner (correct)

- The diagram's grid system and revision history

Why is it important to understand the information contained in the title block and other non-diagram areas?

Why is it important to understand the information contained in the title block and other non-diagram areas?

What is the potential consequence of not understanding the non-diagram areas of a plant diagram?

What is the potential consequence of not understanding the non-diagram areas of a plant diagram?

How many types of plant diagrams are mentioned in the text?

How many types of plant diagrams are mentioned in the text?

What is the purpose of a grid system on diagrams?

What is the purpose of a grid system on diagrams?

What is the primary function of a Process Flow Diagram (PFD)?

What is the primary function of a Process Flow Diagram (PFD)?

What is the purpose of a revision block on a diagram?

What is the purpose of a revision block on a diagram?

What is the purpose of the cloud method in indicating revisions on a diagram?

What is the purpose of the cloud method in indicating revisions on a diagram?

What is typically included in the notes and legends section of a diagram?

What is typically included in the notes and legends section of a diagram?

What is the purpose of a PFD in plant operation?

What is the purpose of a PFD in plant operation?

What is represented by the symbol with a circle and a horizontal line through it?

What is represented by the symbol with a circle and a horizontal line through it?

What is the purpose of a General Arrangement (GA) diagram?

What is the purpose of a General Arrangement (GA) diagram?

What is the typical layout of a PFD?

What is the typical layout of a PFD?

What is the function of the level recording controller (LRC) in Figure 7?

What is the function of the level recording controller (LRC) in Figure 7?

What is the purpose of the process lines on a PFD?

What is the purpose of the process lines on a PFD?

What is the purpose of a block diagram?

What is the purpose of a block diagram?

What is the purpose of the system ratings and operating values on a PFD?

What is the purpose of the system ratings and operating values on a PFD?

What is the primary characteristic of PFDs?

What is the primary characteristic of PFDs?

What is represented by the letter 'F' in an instrument symbol?

What is represented by the letter 'F' in an instrument symbol?

What is the purpose of an equipment diagram?

What is the purpose of an equipment diagram?

What is the significance of the control lines in Figure 7?

What is the significance of the control lines in Figure 7?

What is the purpose of a P&ID diagram?

What is the purpose of a P&ID diagram?

What is represented by the symbol 'LT' in Figure 7?

What is represented by the symbol 'LT' in Figure 7?

What is the arrangement guideline for block diagrams?

What is the arrangement guideline for block diagrams?

What is typically shown in a Process Flow Schematic Diagram?

What is typically shown in a Process Flow Schematic Diagram?

What is the primary purpose of a Piping and Instrumentation Diagram (P&ID)?

What is the primary purpose of a Piping and Instrumentation Diagram (P&ID)?

What type of information is included in a P&ID?

What type of information is included in a P&ID?

When is a P&ID typically used?

When is a P&ID typically used?

What is the purpose of a P&ID legend?

What is the purpose of a P&ID legend?

What type of information is included in the P&ID instrumentation symbols?

What type of information is included in the P&ID instrumentation symbols?

What is the difference between a P&ID and a PFD?

What is the difference between a P&ID and a PFD?

What is included in the equipment details on a P&ID?

What is included in the equipment details on a P&ID?

What is the purpose of P&ID diagrams in the construction phase?

What is the purpose of P&ID diagrams in the construction phase?

What is the benefit of using P&IDs in plant operation and maintenance?

What is the benefit of using P&IDs in plant operation and maintenance?

What is the primary purpose of identifying the features common to all standard plant diagrams?

What is the primary purpose of identifying the features common to all standard plant diagrams?

What is the significance of the title block in a plant diagram?

What is the significance of the title block in a plant diagram?

What is the consequence of neglecting the non-diagram areas of a plant diagram?

What is the consequence of neglecting the non-diagram areas of a plant diagram?

What is the primary benefit of understanding the different parts of a plant diagram?

What is the primary benefit of understanding the different parts of a plant diagram?

What is the relationship between the title block and the diagram's validity?

What is the relationship between the title block and the diagram's validity?

What is the primary purpose of dividing standard plant diagrams into five major areas?

What is the primary purpose of dividing standard plant diagrams into five major areas?

What is the primary purpose of a board mounted instrument symbol in a P&ID diagram?

What is the primary purpose of a board mounted instrument symbol in a P&ID diagram?

What is the significance of the second letter in an instrument symbol?

What is the significance of the second letter in an instrument symbol?

What is the purpose of a General Arrangement (GA) diagram?

What is the purpose of a General Arrangement (GA) diagram?

What is the primary characteristic of a block diagram?

What is the primary characteristic of a block diagram?

What is the purpose of an equipment diagram?

What is the purpose of an equipment diagram?

What is the significance of the horizontal line through a circle in an instrument symbol?

What is the significance of the horizontal line through a circle in an instrument symbol?

What is the purpose of the control lines in Figure 7?

What is the purpose of the control lines in Figure 7?

What is the primary purpose of combining equipment, piping, and instrumentation symbols?

What is the primary purpose of combining equipment, piping, and instrumentation symbols?

What is the significance of the letter 'L' in an instrument symbol?

What is the significance of the letter 'L' in an instrument symbol?

What is the purpose of the level recording controller (LRC) in Figure 7?

What is the purpose of the level recording controller (LRC) in Figure 7?

What is the primary function of a P&ID in the pre-construction phase?

What is the primary function of a P&ID in the pre-construction phase?

What is typically included in the equipment details on a P&ID?

What is typically included in the equipment details on a P&ID?

What is the primary difference between a P&ID and a PFD?

What is the primary difference between a P&ID and a PFD?

What is the purpose of the flow lines on a P&ID?

What is the purpose of the flow lines on a P&ID?

What is the primary function of a P&ID in the operation phase?

What is the primary function of a P&ID in the operation phase?

What is the purpose of the instrumentation symbols on a P&ID?

What is the purpose of the instrumentation symbols on a P&ID?

What is the primary function of a P&ID in the maintenance phase?

What is the primary function of a P&ID in the maintenance phase?

What is the purpose of the piping identifiers on a P&ID?

What is the purpose of the piping identifiers on a P&ID?

What is the primary characteristic of a P&ID?

What is the primary characteristic of a P&ID?

What is the purpose of the legend on a P&ID?

What is the purpose of the legend on a P&ID?

What is the primary purpose of including a grid system on a diagram?

What is the primary purpose of including a grid system on a diagram?

What is the main difference between diagrams with a scale and those without a scale?

What is the main difference between diagrams with a scale and those without a scale?

What is the purpose of the revision block on a diagram?

What is the purpose of the revision block on a diagram?

What is the significance of the process lines on a PFD?

What is the significance of the process lines on a PFD?

What is the purpose of the notes and legends section of a diagram?

What is the purpose of the notes and legends section of a diagram?

What is the primary characteristic of PFDs?

What is the primary characteristic of PFDs?

What is the purpose of the cloud method in indicating revisions on a diagram?

What is the purpose of the cloud method in indicating revisions on a diagram?

What is typically shown on a PFD?

What is typically shown on a PFD?

What is the purpose of a PFD in plant operation?

What is the purpose of a PFD in plant operation?

What is the significance of the layout of a PFD?

What is the significance of the layout of a PFD?

The grid system of a standard plant diagram is typically used to identify the diagram title and diagram number.

The grid system of a standard plant diagram is typically used to identify the diagram title and diagram number.

All standard plant diagrams can be divided into four major areas or parts.

All standard plant diagrams can be divided into four major areas or parts.

The revision block of a diagram contains information about the diagram title and diagram number.

The revision block of a diagram contains information about the diagram title and diagram number.

The notes and legends section of a diagram is used to provide information about the diagram title and diagram number.

The notes and legends section of a diagram is used to provide information about the diagram title and diagram number.

Understanding the information contained in the title block and other non-diagram areas is not as important as being able to read the diagram itself.

Understanding the information contained in the title block and other non-diagram areas is not as important as being able to read the diagram itself.

The engineering diagram is the portion of the diagram that contains the diagram title and diagram number.

The engineering diagram is the portion of the diagram that contains the diagram title and diagram number.

P&ID diagrams are drawn to scale and show the exact orientation of equipment.

P&ID diagrams are drawn to scale and show the exact orientation of equipment.

P&ID diagrams show the actual physical locations of equipment in the plant.

P&ID diagrams show the actual physical locations of equipment in the plant.

P&ID diagrams include details of instrumentation identified for monitoring, indicating, transmitting, and recording devices.

P&ID diagrams include details of instrumentation identified for monitoring, indicating, transmitting, and recording devices.

P&ID diagrams are used only during the design and pre-construction phases of a project.

P&ID diagrams are used only during the design and pre-construction phases of a project.

P&ID diagrams are used to develop detailed lists of parts, equipment, instrumentation, and electrical devices from which cost estimates and bid proposals can be generated.

P&ID diagrams are used to develop detailed lists of parts, equipment, instrumentation, and electrical devices from which cost estimates and bid proposals can be generated.

P&ID diagrams include information on the makeup of fluids in the process.

P&ID diagrams include information on the makeup of fluids in the process.

P&ID diagrams include information on the basic instrumentation orientation.

P&ID diagrams include information on the basic instrumentation orientation.

P&ID diagrams are used to understand the details of the process, its instrumentation control system, and the relationship between process, utility, and electrical systems.

P&ID diagrams are used to understand the details of the process, its instrumentation control system, and the relationship between process, utility, and electrical systems.

P&ID diagrams include detailed piping, isometric diagrams, and equipment or instrument data sheets.

P&ID diagrams include detailed piping, isometric diagrams, and equipment or instrument data sheets.

P&ID diagrams are used only for HVAC systems.

P&ID diagrams are used only for HVAC systems.

PFDs are typically drawn to scale and show exact orientation of equipment in the process.

PFDs are typically drawn to scale and show exact orientation of equipment in the process.

The revision block is used to track changes made to a diagram from its initial release.

The revision block is used to track changes made to a diagram from its initial release.

The cloud method of indicating revisions on a diagram shows all revisions made to the diagram.

The cloud method of indicating revisions on a diagram shows all revisions made to the diagram.

The notes and legends section of a diagram is used to explain standardized symbols and conventions used on the diagram.

The notes and legends section of a diagram is used to explain standardized symbols and conventions used on the diagram.

Diagrams with a scale are used to show functional information about the component or system.

Diagrams with a scale are used to show functional information about the component or system.

A separate PFD may be prepared for each plant process, and more than one process may be shown on a single sheet for simple processes.

A separate PFD may be prepared for each plant process, and more than one process may be shown on a single sheet for simple processes.

The grid system is used to locate specific points on a diagram and is typically composed of numbers and letters that run horizontally and vertically around the diagram's edge.

The grid system is used to locate specific points on a diagram and is typically composed of numbers and letters that run horizontally and vertically around the diagram's edge.

The primary purpose of a PFD is to provide detailed information about the equipment and its layout in the process.

The primary purpose of a PFD is to provide detailed information about the equipment and its layout in the process.

PFDs are good resources for training new personnel and helping with general understanding of the process flows and control strategy.

PFDs are good resources for training new personnel and helping with general understanding of the process flows and control strategy.

The revision block is typically placed beside a triangle or within a cloud shape on the diagram.

The revision block is typically placed beside a triangle or within a cloud shape on the diagram.

The symbol 'L' in an instrument symbol represents Level measurement.

The symbol 'L' in an instrument symbol represents Level measurement.

A General Arrangement (GA) diagram provides exact dimensional relationships between items.

A General Arrangement (GA) diagram provides exact dimensional relationships between items.

Block diagrams represent individual pieces of equipment rather than unit operations.

Block diagrams represent individual pieces of equipment rather than unit operations.

The level transmitter in Figure 7 sends a modified pneumatic signal to the diaphragm-operated level control valve.

The level transmitter in Figure 7 sends a modified pneumatic signal to the diaphragm-operated level control valve.

Equipment diagrams are used to provide a detailed graphical description of the component and are used as a design tool for fabrication.

Equipment diagrams are used to provide a detailed graphical description of the component and are used as a design tool for fabrication.

The control lines in Figure 7 indicate that the control system is electrical.

The control lines in Figure 7 indicate that the control system is electrical.

The level recording controller (LRC) in Figure 7 adjusts the tank level directly.

The level recording controller (LRC) in Figure 7 adjusts the tank level directly.

Block diagrams represent individual units, such as mixers, furnaces, and reactors, with complex shapes.

Block diagrams represent individual units, such as mixers, furnaces, and reactors, with complex shapes.

The second letter in an instrument symbol represents the measurement type.

The second letter in an instrument symbol represents the measurement type.

A Process Flow Diagram (PFD) is the same as a Piping and Instrumentation Diagram (P&ID).

A Process Flow Diagram (PFD) is the same as a Piping and Instrumentation Diagram (P&ID).

Study Notes

Plant Diagrams

- Standard plant diagrams can be divided into five major areas:

- Title Block

- Grid System

- Revision Block

- Notes and Legends

- Engineering Diagram (graphic portion)

Title Block

- Located at the bottom or lower right corner of a diagram

- Contains information to identify the diagram and verify its validity

- Includes:

- Diagram title, diagram number, site location, and diagram owner

- Signed and dated approval of the plan developers

- Reference list of other diagrams that are related to the system or component

Grid System

- Helps locate a specific point on a diagram

- Consists of letters, numbers, or both that run horizontally and vertically around the diagram's edge

- Common in Piping and Instrument Diagrams (P&ID) and electrical schematic diagrams

Revision Block

- Records changes made to a component or system

- Initially empty, with each revision, an entry is placed in the revision block

- Includes:

- Revision number

- Title or summary of the revision

- Date of the revision

- Two methods to indicate revisions:

- Cloud method: each change is enclosed by a hand-drawn cloud shape

- Circle (or triangle, or other shape) with the revision number next to each affected portion of the diagram

Notes and Legends

- Lists and explains special symbols and conventions used on the diagram

- Important for understanding unique symbols and conventions for each diagram type

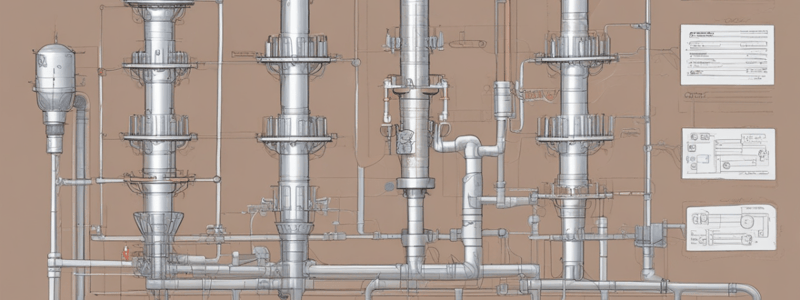

Process Flow Diagram (PFD)

- Simplified schematic of a plant or portion of a plant

- Uses graphic symbols to show major equipment items and process flow between equipment

- Not drawn to scale, but shows inter-relationships between equipment

- Provides valuable information for plant operating and engineering staff

- Typical details shown on a PFD:

- Major process equipment with process line orientation

- Main piping, including major bypass and recirculation lines, and direction of flow

- System ratings and operating values, including flows and rates, pressure, and temperature values

- General configuration and process orientation of equipment

General Arrangement (GA) Diagrams

- Depicts the physical relationship of significant items using projections or perspective views

- Does not identify items, but provides a general description of the configuration and location of significant items in an operating facility

- Does not provide exact dimensional relationships

Block Diagrams

- Shapes represent different unit operations

- Blocks enclose the individual process rather than an individual piece of equipment

- Indicates the special arrangement of equipment and systems

- Does not indicate how the equipment is connected

- Guidelines for creating clear block diagrams:

- Use simple blocks or rectangles to denote individual units

- Note groups of individual units by a single block, rectangle, or characteristic shape

- Process flow streams flowing into and out of the blocks are not represented

- Label the unit operations (i.e., blocks)

- Arrange the diagram so that the process material flows from left to right

Equipment Diagrams

- Provide a detailed graphical description of the component

- Range from simple 2D perspectives to complicated 3D cutaways or assembly diagrams

- Used as a design tool for fabrication and to provide visual perspective in recognizing the component in the operating environment of the plant### Diagrams in Plant Operations

- Diagrams are used to represent complex systems and are essential for plant operation, maintenance, and training.

Plant Diagram Components

- Title Block: contains diagram title, number, site location, and owner

- Grid System: helps locate specific points on the diagram

- Revision Block: tracks changes to the diagram

- Notes and Legend: explains symbols and conventions used in the diagram

- Engineering Diagram (graphic portion): the visual representation of the system

Diagram Types

- Process Flow Diagram (PFD): a simplified schematic of a plant or portion of a plant

- Pipe & Instrument Diagram (P&ID): expands on the PFD to show details of equipment, piping, and instrumentation

- General Arrangement (GA) Diagram: depicts the physical relationship of significant items

- Block Diagram: represents different unit operations

- Electrical Single Line Diagrams and Schematics: shows the electrical connections and relationships

- Equipment Diagrams: provides a detailed graphical description of individual equipment

P&ID Details

- Flow lines: include line identification, size, insulation requirements, and valve sizes and types

- Equipment details: vessel size, insulation requirements, power, external mechanical details, and controls

- Instrumentation: identified for monitoring, indicating, transmitting, recording, and controlling devices

P&ID Purpose

- Used during design and pre-construction to develop detailed lists of parts and equipment

- Used during construction to ensure proper location and interrelationship of equipment

- Used after construction as an operational and training reference for plant operating and engineering staff### Instrumentation Symbols

- Symbols exist for miscellaneous items like transmitters and hand control valves

- Symbols for board mounted and locally mounted instruments are also shown

- Board mounted instruments appear as circles with horizontal lines, while locally mounted instruments have no line

- The first letter of a symbol stands for the measurement type (e.g. F for Flow, P for Pressure, T for Temperature)

- The second letter represents the type of instrument (e.g. I for Indicator, R for Recorder, T for Transmitter)

Instrument Loop Diagrams

- Simple control loops can be created by combining equipment, piping, and instrumentation symbols

- These loops are built into more complete P&ID diagrams

- Figure 7 shows an example of a simple instrument loop that senses and adjusts a tank level

General Arrangement (GA) Diagrams

- GA diagrams depict the physical relationship of significant items using projections or perspective views

- Reference dimensions may be included, but they do not identify items

- GA diagrams provide a general description of the configuration and location of significant items in an operating facility

- They do not provide exact dimensional relationships

Block Diagrams

- Shapes in block diagrams represent different unit operations

- Blocks enclose individual processes rather than individual pieces of equipment

- Block plans indicate the special arrangement of equipment and systems, but do not show how they are connected

- Guidelines for creating clear block diagrams include:

- Using simple blocks or rectangles to denote individual units

- Grouping individual units by a single block, rectangle, or characteristic shape

- Not representing process flow streams flowing into and out of blocks

- Labeling unit operations (blocks)

- Arranging the diagram so that process material flows from left to right

Equipment Diagrams

- System level diagrams always have supporting individual equipment diagrams

- Equipment diagrams provide a detailed graphical description of the component

- They can range from simple 2D perspectives to complicated 3D cutaways or assembly diagrams

- Equipment diagrams are used for design and to provide visual perspective in recognizing components in the operating environment of the plant

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Learn about the different types of diagrams used in plant operations, including Process Flow Diagrams, Pipe & Instrument Diagrams, and more. Discover the common features and symbols used in these diagrams and understand their specific purposes. Test your knowledge of plant diagram layouts and their applications.