Podcast

Questions and Answers

What is the primary function of slip rings in slip ring motors?

What is the primary function of slip rings in slip ring motors?

- To generate a rotating magnetic field

- To enhance the efficiency of the motor

- To connect the motor to the power supply

- To provide continuous current to the rotor windings (correct)

Why are slip ring motors suitable for heavy load applications?

Why are slip ring motors suitable for heavy load applications?

- They provide high starting torque. (correct)

- They can operate without external control.

- They are simpler than squirrel cage motors.

- They have low starting torque.

Which of the following is a disadvantage of slip ring motors?

Which of the following is a disadvantage of slip ring motors?

- They have low torque output.

- They require no maintenance.

- They are always more efficient than other motors.

- They are more complex than squirrel cage motors. (correct)

How can the speed characteristics of a slip ring motor be adjusted?

How can the speed characteristics of a slip ring motor be adjusted?

What type of control system can be used with slip ring motors for precise speed regulation?

What type of control system can be used with slip ring motors for precise speed regulation?

What maintenance consideration is critical for the longevity of slip ring motors?

What maintenance consideration is critical for the longevity of slip ring motors?

In which applications are slip ring motors commonly used?

In which applications are slip ring motors commonly used?

What is the outcome of the rotor windings being connected to slip rings?

What is the outcome of the rotor windings being connected to slip rings?

What happens to external resistance during the starting of a slip ring motor?

What happens to external resistance during the starting of a slip ring motor?

Which of the following statements about the operation of slip ring motors is true?

Which of the following statements about the operation of slip ring motors is true?

Flashcards are hidden until you start studying

Study Notes

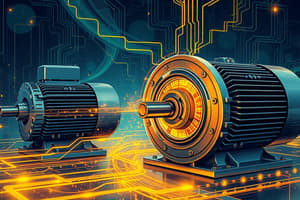

Slip Ring Motors

-

Definition: Slip ring motors are a type of alternating current (AC) motor that uses slip rings to provide continuous current to the rotor windings.

-

Components:

- Stator: Contains a three-phase winding, generating a rotating magnetic field when AC power is supplied.

- Rotor: Has windings connected to slip rings, which allow for external resistance to be added for controlling torque and speed.

- Slip Rings: Conductive rings connected to rotor windings that allow electrical power to be transferred to the rotor.

-

Operation:

- The rotating magnetic field of the stator induces current in the rotor windings.

- Slip rings enable the rotor to maintain a magnetic field, enhancing torque output.

- External resistances can be added to control starting torque and speed characteristics.

-

Advantages:

- High starting torque, suitable for heavy load applications.

- Adjustable speed characteristics using external resistors.

- Better performance in applications requiring variable speed and torque.

-

Disadvantages:

- More complex than squirrel cage motors, requiring additional maintenance.

- Slip rings and brushes can wear out, leading to maintenance challenges.

- Generally less efficient than other motor types under certain conditions.

-

Applications:

- Used in cranes, hoists, and other heavy machinery requiring high starting torque.

- Common in applications involving variable speed drives.

- Employed in wind turbines and large industrial fans.

-

Starting Method:

- Typically started with external resistance connected to the rotor.

- Resistance is gradually reduced as the motor reaches its operating speed.

-

Control Systems:

- Can be controlled through various methods like variable frequency drives (VFDs) for precise speed regulation.

- May include feedback systems for more advanced control in industrial applications.

-

Maintenance Considerations:

- Regular inspection and replacement of brushes and slip rings are necessary for longevity.

- Monitoring of rotor winding temperature and vibration can help prevent failures.

These notes summarize the essential aspects of slip ring motors, focusing on their design, operation, advantages, applications, and maintenance.

Definition and Components

- Slip ring motors are AC motors that utilize slip rings for continuous rotor current.

- The stator comprises a three-phase winding, creating a rotating magnetic field with AC power.

- The rotor is equipped with windings connected to slip rings, allowing the addition of external resistance for torque and speed control.

- Slip rings are conductive rings facilitating electrical power transfer to the rotor.

Operation

- The stator's rotating magnetic field induces current within the rotor windings.

- Slip rings help maintain a magnetic field in the rotor, boosting torque output.

- External resistances can be integrated to manage starting torque and speed characteristics.

Advantages

- High starting torque makes slip ring motors ideal for heavy load applications.

- Speed characteristics can be adjusted using external resistors for flexibility.

- More effective in applications requiring variable speed and torque conditions.

Disadvantages

- Increased complexity compared to squirrel cage motors leads to higher maintenance demands.

- Wear of slip rings and brushes presents maintenance challenges.

- May exhibit lower efficiency compared to other motor types under certain situations.

Applications

- Commonly utilized in cranes, hoists, and heavy machinery needing high starting torque.

- Suitable for variable speed drive applications.

- Found in wind turbines and large industrial fans due to their performance characteristics.

Starting Method

- Typically, slip ring motors are started with external resistance connected to the rotor.

- As the motor approaches its operating speed, the resistance is gradually reduced.

Control Systems

- Control can be achieved using variable frequency drives (VFDs) for precise speed regulation.

- Advanced feedback systems may be included in industrial applications for enhanced control.

Maintenance Considerations

- Regular inspection and replacement of brushes and slip rings are essential for optimal operation.

- Monitoring rotor winding temperature and vibration can prevent potential failures and extend motor life.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.