Podcast

Questions and Answers

What is the primary function of the screen and spacer filter?

What is the primary function of the screen and spacer filter?

- To act as a last chance filter

- To filter oil flowing into the bearing

- To filter oil flowing out of the pump

- To filter oil flowing through the system (correct)

What is the purpose of the threaded element in a thread filter?

What is the purpose of the threaded element in a thread filter?

- To increase oil flow

- To reduce oil pressure

- To filter oil (correct)

- To mix oil and air

Why is an oil bypass valve necessary in an oil filter?

Why is an oil bypass valve necessary in an oil filter?

- To reduce oil pressure

- To meet regulatory requirements (correct)

- To increase oil flow

- To filter oil more efficiently

What type of filter is typically used as a pressure filter?

What type of filter is typically used as a pressure filter?

What is the purpose of the perforated tube in a screen and spacer filter?

What is the purpose of the perforated tube in a screen and spacer filter?

Where is a thread filter typically located?

Where is a thread filter typically located?

What determines the degree of filtration in a thread filter?

What determines the degree of filtration in a thread filter?

What happens to the other channel when both channels are serviceable and the active channel alternates with each engine start?

What happens to the other channel when both channels are serviceable and the active channel alternates with each engine start?

What is the purpose of the dual sensors fitted on valves and actuators?

What is the purpose of the dual sensors fitted on valves and actuators?

What happens if both channels of the EEC fail?

What happens if both channels of the EEC fail?

What is the function of the Engine Rating Plug?

What is the function of the Engine Rating Plug?

What is the purpose of the hydromechanical unit?

What is the purpose of the hydromechanical unit?

What is the function of the electrical hydraulic servo valve (EHSV)?

What is the function of the electrical hydraulic servo valve (EHSV)?

What happens in one system upon dual channel failure?

What happens in one system upon dual channel failure?

What is attached to the engine fan case with a lanyard?

What is attached to the engine fan case with a lanyard?

What primarily changes the mass of air induced through the engine?

What primarily changes the mass of air induced through the engine?

How does the FCU adjust the fuel flow to the engine?

How does the FCU adjust the fuel flow to the engine?

Which of the following is NOT an input for the typical FCU?

Which of the following is NOT an input for the typical FCU?

What effect does a mismatch between airflow and fuel flow have on engine performance?

What effect does a mismatch between airflow and fuel flow have on engine performance?

Which condition is adjusted by the servo system in the fuel control unit?

Which condition is adjusted by the servo system in the fuel control unit?

What is the role of the HP fuel pump in the engine fuel system?

What is the role of the HP fuel pump in the engine fuel system?

What modern technology automatically compensates for fuel density in engines?

What modern technology automatically compensates for fuel density in engines?

What happens to engine speed during rapid acceleration if airflow is not properly adjusted?

What happens to engine speed during rapid acceleration if airflow is not properly adjusted?

Which of the following statements accurately describes the primary purpose of a combustor drain valve?

Which of the following statements accurately describes the primary purpose of a combustor drain valve?

What mechanism triggers the opening of a combustor drain valve after engine shutdown?

What mechanism triggers the opening of a combustor drain valve after engine shutdown?

What is the primary concern regarding a malfunctioning combustor drain valve?

What is the primary concern regarding a malfunctioning combustor drain valve?

What is the primary reason for the current regulations prohibiting the dumping of fuel from aircraft in flight?

What is the primary reason for the current regulations prohibiting the dumping of fuel from aircraft in flight?

What is the primary function of a fuel recycling system?

What is the primary function of a fuel recycling system?

What is the purpose of introducing bleed air into the dump port of a fuel recycling system?

What is the purpose of introducing bleed air into the dump port of a fuel recycling system?

What is the function of the float valve in a fuel recycling system?

What is the function of the float valve in a fuel recycling system?

Which of the following is NOT a potential outcome of a malfunctioning drain valve?

Which of the following is NOT a potential outcome of a malfunctioning drain valve?

What role does the air balance chamber play in relation to the compressor thrust bearing?

What role does the air balance chamber play in relation to the compressor thrust bearing?

In what scenario might an engine not require an air balance chamber?

In what scenario might an engine not require an air balance chamber?

What is the primary use of customer bleed air in turbine engines?

What is the primary use of customer bleed air in turbine engines?

How is low-pressure bleed air characterized in a gas turbine engine?

How is low-pressure bleed air characterized in a gas turbine engine?

What is the function of the pre-cooler in relation to engine bleed air?

What is the function of the pre-cooler in relation to engine bleed air?

What role does the fan air temperature sensor play in the cooling process?

What role does the fan air temperature sensor play in the cooling process?

What happens to the fan air after passing through the heat exchanger in the cooling process?

What happens to the fan air after passing through the heat exchanger in the cooling process?

What is a distinguishing feature of high-pressure bleed air?

What is a distinguishing feature of high-pressure bleed air?

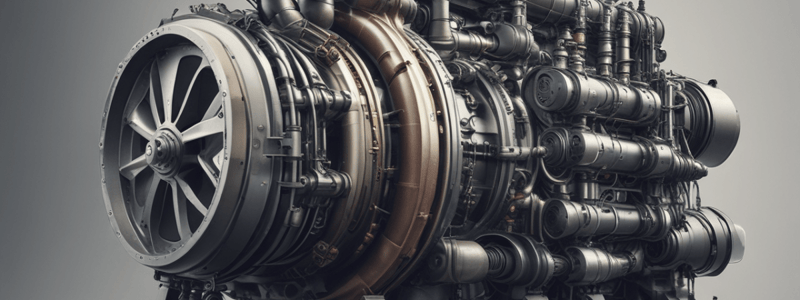

What is the primary function of a gas turbine system?

What is the primary function of a gas turbine system?

What is the purpose of the combustion chamber in a gas turbine system?

What is the purpose of the combustion chamber in a gas turbine system?

What is a major advantage of gas turbine systems?

What is a major advantage of gas turbine systems?

In which industry are gas turbines used to power pumps and compressors?

In which industry are gas turbines used to power pumps and compressors?

What is the purpose of the turbine in a gas turbine system?

What is the purpose of the turbine in a gas turbine system?

What is a challenge associated with gas turbine systems?

What is a challenge associated with gas turbine systems?

What is a benefit of gas turbines in terms of environmental impact?

What is a benefit of gas turbines in terms of environmental impact?

What is the purpose of the generator in a gas turbine system?

What is the purpose of the generator in a gas turbine system?

Flashcards are hidden until you start studying

Study Notes

Screen and Spacer Filters

- Utilize disc-shaped elements stacked on an element support.

- Oil flows through both sides of filter discs separated by a spacer into a perforated tube.

- Commonly used as pressure filters, positioned downstream of the pump.

Thread Filters

- Serve as “last chance” filters before oil enters bearings.

- Feature an inner threaded element and an unthreaded outer casing.

- Filtration efficiency can be adjusted by selecting pitch of threads; finer pitches provide better filtration.

Oil Filter Bypass

- Mandatory design for oil filters to allow full oil flow even if blocked.

- Typically achieved through an oil bypass valve that diverts oil when the filter is clogged.

- Airflow changes due to altitude, temperature, and speed affect engine fuel-air ratio.

Fuel Flow Variation

- High-Pressure (HP) fuel pump output adjusted through:

- Piston stroke variation for piston type pumps.

- Recirculation of excess fuel for gear type pumps.

- Pump output adjustments respond to throttle movement, air temperature, pressure changes, rapid accelerations, and engine performance signals.

Engine Electronic Control (EEC)

- Modern systems with two redundant channels for reliability, each with its own processor and sensors.

- Active channel alternates with each engine start; can operate even with some faults.

- EEC controls subsystems such as fuel and air oil coolers, bleed valves, and turbine cooling systems.

Drain Valves

- Mechanical devices in combustor to prevent fuel accumulation by opening based on pressure changes.

- According to operation, valve prevents risks of hot starts or after-fires due to fuel residue.

- Essential for maintenance and effective engine starting procedures.

Drain Tanks and Recycling Systems

- Current regulations mandate that dumped fuel be captured; direct ground dumping is prohibited.

- Recycling methods include returning fuel to the aircraft supply or using bleed air to expel fuel through nozzles.

- Balanced systems prevent compressor forward thrust by utilizing air pressure in balance chambers.

Customer Bleed Air Systems

- Extracted from the engine compressor for aircraft functions like anti-icing and cabin pressurization.

- Low-pressure bleed air comes from early compressor stages, while high-pressure air is sourced from later stages.

Pre-cooler Functionality

- Hot engine bleed air is cooled before use in aircraft systems.

- Utilizes cold airflow from the engine’s fan area as a cooling medium through a heat exchanger.

- Controlled by a fan air temperature sensor affecting the position of the Fan Air Modulating Valve for optimal air cooling.

Overview

- Gas turbine systems utilize a turbine in internal combustion engines for power generation.

- Widely employed in power generation, oil and gas, and aerospace sectors.

- Notable for high efficiency and superior power-to-weight ratios.

Components

- Compressor: Ingests air, compresses it, and mixes it with fuel.

- Combustion Chamber: Site of fuel ignition, releasing significant energy.

- Turbine: Transforms energy from combustion into mechanical energy.

- Generator: Converts mechanical energy into electrical energy, primarily in power generation.

Working Principle

- Air enters the compressor where it undergoes compression.

- Fuel is injected and combined with the compressed air in the combustion chamber.

- Ignition of the air-fuel mixture generates energy.

- Resulting hot gases expand through the turbine, producing power.

- The turbine drives the generator, creating electrical energy from mechanical input.

Advantages

- Achieves a high power-to-weight ratio, enhancing mobility and efficiency.

- Efficiency rates can reach up to 40%, making them cost-effective.

- Produces lower emissions compared to traditional fossil fuel power systems.

- Quick startup and responsive operations make them versatile.

- Capable of using diverse fuels, such as natural gas and biofuels.

Applications

- Power Generation: Central to producing electricity in various power plants.

- Oil and Gas: Vital for powering pumps and compressors in extraction processes.

- Aerospace: Essential for jet engines, providing thrust for aircraft.

- Industrial: Powers mechanical equipment like compressors and pumps in industrial settings.

Challenges and Limitations

- Maintenance costs can be significantly high over the system's lifetime.

- Initial investment is considerable, posing a barrier to adoption.

- Some designs exhibit limited fuel flexibility, restricting operational versatility.

- Noise and vibration produced can present significant operational challenges.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.