Podcast

Questions and Answers

What is the most widely used casting process?

What is the most widely used casting process?

- Investment Casting

- Lost wax casting

- Sand Casting (correct)

- Centrifugal Casting

What is the material used to form the cavity in sand casting?

What is the material used to form the cavity in sand casting?

- Plastic

- Sand (correct)

- Metal

- Wax

Why does sand casting typically have a low production rate?

Why does sand casting typically have a low production rate?

- Complex process cycle

- The need to destroy the sand mold to remove the part (correct)

- High cost of materials

- Limited availability of metal alloys

What types of metal components can be produced using sand casting?

What types of metal components can be produced using sand casting?

Which type of equipment is involved in the sand casting process?

Which type of equipment is involved in the sand casting process?

Flashcards are hidden until you start studying

Study Notes

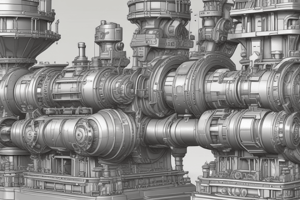

Sand Casting Process Overview

- Sand casting is the most widely used casting process due to its versatility and cost-effectiveness.

Cavity Formation in Sand Casting

- The cavity in sand casting is formed using sand mixed with a binding agent, typically clay, to create the mold shape.

Production Rate in Sand Casting

- Sand casting typically has a low production rate because each mold must be created individually, making it a slower process compared to other methods like die casting.

Metal Components Produced

- A wide range of metal components can be produced using sand casting, including complex shapes and large items like engine blocks, aerospace components, and art sculptures.

Equipment Used in Sand Casting

- Equipment involved in the sand casting process includes a pattern for creating molds, a sand mixer for preparing the sand, a molding box for shaping the mold, and a furnace for melting metal.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.