Podcast

Questions and Answers

What is a recommended solution to prevent saltwater from entering the air supply?

What is a recommended solution to prevent saltwater from entering the air supply?

- Keeping air intake vents underwater for better cooling

- Using low-efficiency filters designed for marine environments

- Locating air intake vents above the waterline and away from splash zones (correct)

- Allowing unrestricted access for saltwater into the air system

How can debris be harmful to the engine's air supply system?

How can debris be harmful to the engine's air supply system?

- Debris can enhance engine performance

- Debris is necessary for proper air filtration

- Debris can cause damage to the engine components (correct)

- Debris has no impact on the air supply system

What is NOT a method to prevent saltwater intrusion into the air supply?

What is NOT a method to prevent saltwater intrusion into the air supply?

- Locating air intake vents below the waterline (correct)

- Locating air intake vents above the waterline

- Ensuring the vent's design prevents saltwater entry

- Using high-efficiency filters designed for marine environments

Why is protecting the air supply from dust important?

Why is protecting the air supply from dust important?

What is a recommended measure to prevent dust from entering the air supply?

What is a recommended measure to prevent dust from entering the air supply?

Which of the following is a proper way to prevent saltwater from entering the air supply?

Which of the following is a proper way to prevent saltwater from entering the air supply?

Why is it important to avoid using air intake vents near construction sites, dusty areas, or other sources of debris?

Why is it important to avoid using air intake vents near construction sites, dusty areas, or other sources of debris?

What can help ensure the longevity and effectiveness of your engine?

What can help ensure the longevity and effectiveness of your engine?

What is the main function of the intake system in a naturally aspirated engine?

What is the main function of the intake system in a naturally aspirated engine?

Which component of the intake system plays a crucial role in preventing unwanted particles from entering the combustion chambers?

Which component of the intake system plays a crucial role in preventing unwanted particles from entering the combustion chambers?

How does the throttle body control the airflow into the engine?

How does the throttle body control the airflow into the engine?

What is the purpose of the intake manifold in a naturally aspirated engine?

What is the purpose of the intake manifold in a naturally aspirated engine?

What component in the intake system measures the volume of air entering the engine?

What component in the intake system measures the volume of air entering the engine?

How does the intake manifold runner contribute to engine performance?

How does the intake manifold runner contribute to engine performance?

What role does the intake port play in the engine?

What role does the intake port play in the engine?

How can an air ionizer benefit the engine's operation?

How can an air ionizer benefit the engine's operation?

Which factor is critical in designing an optimal intake system for an engine?

Which factor is critical in designing an optimal intake system for an engine?

What future technology could enhance an engine's performance without using a belt-driven turbocharger?

What future technology could enhance an engine's performance without using a belt-driven turbocharger?

Flashcards are hidden until you start studying

Study Notes

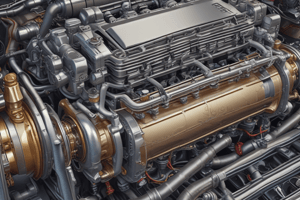

Protecting Your Engine: Keeping Salt, Debris, and Dust Out of Your Air Supply

In the realm of industrial machinery and engine maintenance, ensuring a clean and uncontaminated air supply is paramount. Saltwater, debris, and dust, if allowed to enter the air system, can cause serious damage that may lead to costly repairs or even replacement of the engine. In this article, we'll explore the steps and precautions necessary to keep your machinery running smoothly and avoid these common air supply contaminants.

Preventing Saltwater from Entering the Air Supply

Saltwater, a major concern for engines in marine environments, can corrode and degrade metal components. It's essential to protect your air supply from saltwater intrusion, as it can be detrimental to the engine's air filtration system and its components.

Solutions to prevent saltwater from entering the air supply include:

- Locating air intake vents above the waterline and away from splash zones.

- Making sure the vent's design eliminates the possibility of saltwater entering the vent.

- Using high-efficiency filters designed for marine environments to trap saltwater particles before they can reach the engine.

Preventing Debris from Entering the Air Supply

Debris, such as dirt, dust, and other particulate matter, can easily be drawn into the air supply and cause damage to the engine.

To keep debris out of your air supply, consider the following:

- Installing a high-efficiency air filtration system that can capture and remove particles as small as 0.5 microns.

- Cleaning the air filters regularly to ensure they are functioning optimally.

- Avoiding the use of air intake vents near construction sites, dusty areas, or other sources of debris.

Preventing Dust from Entering the Air Supply

Dust, a common contaminant in industrial environments, can accumulate on the engine and cause overheating or other issues.

To keep dust out of your air supply, follow these guidelines:

- Locating air intake vents away from areas with high dust concentrations.

- Using high-efficiency filters designed for dust-laden environments to trap dust particles before they can reach the engine.

- Regularly cleaning the air filters and monitoring their efficiency.

Conclusion

By adopting the preventative measures mentioned above, you can ensure the longevity and effectiveness of your engine and avoid costly repairs related to contaminated air supply. Keeping an eye on your equipment and implementing proper maintenance techniques is key to maintaining a clean air supply and a healthy engine. Remember, an ounce of prevention is worth a pound of cure when it comes to protecting your machinery from the damaging effects of saltwater, debris, and dust.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.