Podcast

Questions and Answers

Describe the purpose of routing the overhead vapor from D-330 through the tube side of E-373 before it reaches T-370. What is it being cooled by on the shell side of E-373?

Describe the purpose of routing the overhead vapor from D-330 through the tube side of E-373 before it reaches T-370. What is it being cooled by on the shell side of E-373?

The overhead vapor from D-330 is cooled in E-373 by the overhead vapor from D-370 (Deethenizer Reflux Drum).

Explain why the stream from D-380 is dried in D-362 A/B before being sent to T-370. What potential issues could arise if this stream wasn't properly dried?

Explain why the stream from D-380 is dried in D-362 A/B before being sent to T-370. What potential issues could arise if this stream wasn't properly dried?

The stream from D-380 is dried to prevent issues such as hydrate formation or corrosion within the Deethenizer (T-370). Moisture can cause operational problems.

Describe the path of the vapor from the top of T-370, including all equipment it encounters, until it returns to T-370 as reflux.

Describe the path of the vapor from the top of T-370, including all equipment it encounters, until it returns to T-370 as reflux.

The overhead vapor from T-370 goes to E-370 (Deethenizer Condenser), then to D-370, and finally back to T-370 as reflux via P-370 A/B (Deethenizer Reflux Pumps).

The bottoms of T-370 are routed to E-375. What heats the bottoms in E-375, and what is done with the overhead vapors from E-375?

The bottoms of T-370 are routed to E-375. What heats the bottoms in E-375, and what is done with the overhead vapors from E-375?

Describe what happens to any liquid that exits the bottom of D-375, and explain why it is routed to the specified location.

Describe what happens to any liquid that exits the bottom of D-375, and explain why it is routed to the specified location.

Flashcards

E-373 Function

E-373 Function

Cools overhead vapor from D-330 using overhead vapor from D-370.

E-370 (Deethenizer Condenser) Function

E-370 (Deethenizer Condenser) Function

Partially condenses the overhead vapor from T-370 (Deethenizer) using propylene refrigerant.

P-370 A/B (Deethenizer Reflux Pumps) Function

P-370 A/B (Deethenizer Reflux Pumps) Function

Provides reflux to the top of T-370 (Deethenizer).

D-375 (Recycle Cylinder Suction Drum) Function

D-375 (Recycle Cylinder Suction Drum) Function

Signup and view all the flashcards

E-375 (Deethenizer Reboiler) Function

E-375 (Deethenizer Reboiler) Function

Signup and view all the flashcards

Study Notes

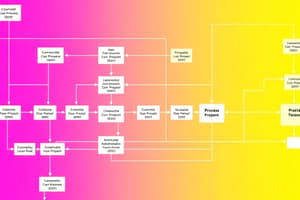

- Overhead vapor from D-330 cools in E-373 via overhead vapor from D-370, then goes to T-370.

- A stream from D-380 recycles through C-360A/B, dries in D-362A/B, filters in F-362, then enters T-370.

- Overhead vapor from T-370 partially condenses in E-370 using propylene refrigerant from D-510.

- The partially condensed vapor goes to D-370.

- Liquid from D-370 returns to T-370 as reflux via P-370A/B.

- Most vapor from D-370 goes to D-375, with a small stream to E-373.

- Liquid from D-375's bottom goes to T-350, vapor from the top goes to C-360A/B.

- Vapor from C-360A/B joins T-370's overhead vapor, both going to E-370.

- T-370 bottoms heat in E-375 using 100 psig steam, and overhead vapors return to T-370.

- Liquid from E-375's bottom goes to T-380.

Equipment Descriptions

- Equipment descriptions provide details on size, shape, internals, and features.

E-373 (Purge Gas Heater)

- A shell and tube, U-tube heat exchanger.

- Cools recycle ethylene vapor (tube side) with overhead vapor from D-370 (shell side).

- It cools ethylene vapor before it goes to T-370.

E-370 (Deethenizer Condenser)

- A shell and tube, U-tube heat exchanger, with a kettle-shaped shell.

- Cools overhead ethylene vapor from T-370 (tube side) with propylene refrigerant from D-510 (shell side).

- Condenses overhead vapor, which is then separated in D-370 for use as reflux on T-370.

D-370 (Deethenizer Reflux Drum)

- Measures 5’D x 12’L.

- Separates liquid for reflux on T-370 from non-condensed vapor.

T-370 (Deethenizer)

- Measures 42”D x 50’5”L.

- Purifies recycled ethylene by removing butene and limits ethane concentration.

- Has perforated trays that only pass vapor (up) and liquid (down).

- Heavier molecules collect as liquid at the bottom, lighter molecules as vapor at the top.

D-362A/B (Deethenizer Feed Dryers)

- Measure 3’D x 44’6”L.

- They remove moisture from T-370's lower feed stream to prevent hydrate formation and catalyst deactivation.

- Gas exiting the drier should contain less than 1 ppm of water.

- One drier works while the other is on standby or regenerates.

F-362 (Deethenizer Feed Filter)

- Measures 8 ½”D x 4’4”L; a cartridge type filter.

- Removes molecular sieve fines from the feed stream to T-370.

P-370A/B (Deethenizer Reflux Pumps)

- Single-stage centrifugal pumps, driven by 7.5 HP 3510 RPM electric motors.

- They circulate reflux to T-370.

- Equipped with chill-down lines for cooling before going online.

- One pump is normally in service, with the other on standby.

E-375 (Deethenizer Reboiler)

- Heats the contents of a fractionation column for separation by boiling points.

- Can be a shell and tube exchanger or a fired heater.

- E-375 is a shell and tube exchanger that heats T-370 bottoms (shell side) with 100 psig steam (tube side).

- It heats T-370 bottoms prior to being routed back to T-370.

D-375 (Recycle Cylinder Suction Drum)

- Measures 3’6”D x 8’L.

- Has an internal demister pad under the top vapor outlet.

- Removes entrained liquid from the vapor.

- Vapor enters on the upper side, liquid exits the bottom, and vapor exits the top.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.