Podcast

Questions and Answers

Additive manufacturing (AM) creates objects through sequential ______.

Additive manufacturing (AM) creates objects through sequential ______.

layering

Fused filament fabrication (FFF) is the most commonly used additive material ______ process.

Fused filament fabrication (FFF) is the most commonly used additive material ______ process.

extrusion

In sheet lamination, sheets of material are ______ together to create an object.

In sheet lamination, sheets of material are ______ together to create an object.

joined

FDM stands for fused deposition ______.

FDM stands for fused deposition ______.

Ultrasonic additive manufacturing (UAM) binding layers uses principles of ultrasonic ______ to produce metal parts.

Ultrasonic additive manufacturing (UAM) binding layers uses principles of ultrasonic ______ to produce metal parts.

A bonding adhesive is used to join ______ sheets.

A bonding adhesive is used to join ______ sheets.

In binder jetting, a modified version of the ______ printing process is used.

In binder jetting, a modified version of the ______ printing process is used.

Directed energy deposition (DED) uses a ______ source to melt metal.

Directed energy deposition (DED) uses a ______ source to melt metal.

The vat photopolymerization process uses a vat filled with photosensitive liquid ______.

The vat photopolymerization process uses a vat filled with photosensitive liquid ______.

Powder bed fusion processes can create both plastic and ______ parts.

Powder bed fusion processes can create both plastic and ______ parts.

Flashcards are hidden until you start studying

Study Notes

Definition and Principles of Additive Manufacturing

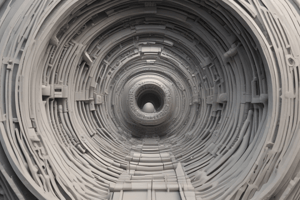

- Additive Manufacturing (AM) refers to technologies that create objects by sequentially layering materials.

- Terminology replaced "rapid prototyping" (RP) to better reflect the process of manufacturing parts directly from 3D CAD models.

- Operates without complex process planning, simplifying the production of intricate 3D objects.

- Each layer represents a thin cross-section from the CAD model, approximating the original design in physical form.

Additive Manufacturing Processes

- Material Extrusion: Involves pushing thermoplastic through a heated nozzle layer by layer.

- Fused Filament Fabrication (FFF): The most common type, using materials like ABS and PLA.

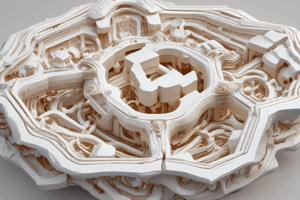

- Sheet Lamination (LOM): Joins sheets of material to form objects; useful for complex geometries.

- Ultrasonic Additive Manufacturing (UAM): Uses ultrasonic welding to bind metal parts from sheets.

- Binder Jetting: Creates solid objects using various materials via a process similar to inkjet printing without heat.

- Material Jetting: Deposits droplets of thermoplastic and cures with UV light, enabling full-color output.

- Directed Energy Deposition (DED): Melts metal powder or wire using a laser or electron beam for part creation or repair.

- Powder Bed Fusion (PBF): Melts material powder layer by layer using lasers or electron beams.

- Types include Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), and Electron Beam Melting (EBM).

- Vat Photopolymerization: Utilizes a vat of photosensitive resin, cured by light, to build parts layer by layer.

Types of 3D Printers and Technologies

- Fused Deposition Modeling (FDM): Utilizes thermoplastics like PLA and ABS.

- Powder-based Processes: Includes DMLS and EBM, suitable for various metal and ceramic powders.

- Laminated Object Manufacturing (LOM): Employs materials like paper and metal foil.

- Stereolithography (SLA)/Digital Light Processing (DLP): Uses photopolymers and liquid resin for fine detail.

Types of 3D Printing Materials

- Plastics: Commonly used with FDM, made from:

- Polylactic Acid (PLA): Eco-friendly, biodegradable; expected to dominate 3D printing.

- Acrylonitrile Butadiene Styrene (ABS): Strong and flexible; popularly used for toys and crafts.

- Polyvinyl Alcohol (PVA): A low-cost option suitable for temporary support materials.

- Polycarbonate (PC): Works at high temperatures, used for low-cost fittings.

- Powdered Materials: Common in advanced printers, includes:

- Polyamide (Nylon): Offers strength and flexibility, ideal for intricate parts.

- Alumide: Strong, used for industrial prototypes.

- Resin Types: Noted for limited flexibility; reaches solid state through UV exposure.

- High-detail, paintable, and transparent resins offer varying qualities for detailed prints.

- Metal: DMLS enables the use of diverse metals, including:

- Stainless Steel: For utensils and cookware.

- Titanium: For strong fixtures.

- Composites: Carbon fiber enhances plastic strength, and graphene offers flexibility and conductivity.

Future Trends

- Carbon fiber printing is anticipated to evolve, potentially replacing slower methods.

- Graphene's versatility in applications such as flexible devices and solar panels makes it appealing for future manufacturing processes.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.