Podcast

Questions and Answers

Match the type of pressure relief valve with its characteristic:

Match the type of pressure relief valve with its characteristic:

Relief Valve = Gradual opening, used for incompressible fluids Safety Valve = Rapid opening, used for compressible fluids Pressure Relief Valve = Acts on inlet static pressure, recloses after normal conditions Temperature and Pressure (T&P) Relief Valve = Actuated by pressure or temperature at the valve inlet

Match the pressure relief valve type with its application:

Match the pressure relief valve type with its application:

Safety Relief Valve = Compressible or incompressible fluids Relief Valve = Incompressible fluids Temperature and Pressure (T&P) Relief Valve = Temperature and pressure sensitive systems Pressure Relief Valve = General purpose pressure relief

Match the term with its definition from ASME PTC-25:

Match the term with its definition from ASME PTC-25:

Pressure Relief Valve = Acts on inlet static pressure, recloses after normal conditions Temperature and Pressure (T&P) Relief Valve = Actuated by pressure or temperature at the valve inlet Relief Valve = Gradual opening, used for incompressible fluids Safety Valve = Rapid opening, used for compressible fluids

Match the standard with its description:

Match the standard with its description:

Match the type of fluid with the suitable pressure relief valve:

Match the type of fluid with the suitable pressure relief valve:

Match the characteristic with the type of pressure relief valve:

Match the characteristic with the type of pressure relief valve:

Match the valve type with its purpose:

Match the valve type with its purpose:

Match the type of pressure relief valve with its operation:

Match the type of pressure relief valve with its operation:

Match the following components of a safety valve with their corresponding functions:

Match the following components of a safety valve with their corresponding functions:

Match the following terms with their corresponding definitions:

Match the following terms with their corresponding definitions:

Match the following scenarios with their corresponding effects on the safety valve:

Match the following scenarios with their corresponding effects on the safety valve:

Match the following regulations with their corresponding requirements:

Match the following regulations with their corresponding requirements:

Match the following components with their corresponding purposes:

Match the following components with their corresponding purposes:

Match the following scenarios with their corresponding effects on the valve:

Match the following scenarios with their corresponding effects on the valve:

Match the following components with their corresponding functions:

Match the following components with their corresponding functions:

Match the following terms with their corresponding effects on the valve:

Match the following terms with their corresponding effects on the valve:

Match the following components with their corresponding purposes:

Match the following components with their corresponding purposes:

Match the following components with their functions in a safety valve:

Match the following components with their functions in a safety valve:

Match the following scenarios with their corresponding effects on the valve:

Match the following scenarios with their corresponding effects on the valve:

Match the following safety valve characteristics with their corresponding values:

Match the following safety valve characteristics with their corresponding values:

Match the following safety valve installation requirements with their corresponding locations:

Match the following safety valve installation requirements with their corresponding locations:

Match the following safety valve regulations with their corresponding sections:

Match the following safety valve regulations with their corresponding sections:

Match the following safety valve adjustments with their effects:

Match the following safety valve adjustments with their effects:

Match the following safety valve components with their positions:

Match the following safety valve components with their positions:

Match the following ASME BPVC codes with their corresponding regulations:

Match the following ASME BPVC codes with their corresponding regulations:

Match the following safety valve characteristics with their corresponding materials:

Match the following safety valve characteristics with their corresponding materials:

Match the following safety valve components with their corresponding functions:

Match the following safety valve components with their corresponding functions:

Match the following safety valve regulations with their corresponding temperatures:

Match the following safety valve regulations with their corresponding temperatures:

Match the following safety valve characteristics with their corresponding effects:

Match the following safety valve characteristics with their corresponding effects:

Match the following safety valve components with their corresponding purposes:

Match the following safety valve components with their corresponding purposes:

Match the following safety valve regulations with their corresponding capacities:

Match the following safety valve regulations with their corresponding capacities:

Match the following safety valve characteristics with their corresponding applications:

Match the following safety valve characteristics with their corresponding applications:

Match the following safety valve components with their corresponding actions:

Match the following safety valve components with their corresponding actions:

Match the following safety valve regulations with their corresponding requirements:

Match the following safety valve regulations with their corresponding requirements:

Flashcards are hidden until you start studying

Study Notes

Pressure Relief Valves

- Automatically open to relieve pressure and then automatically reclose

- Exist in many different varieties, with 11 types defined by ASME PTC-25 Pressure Relief Devices

- Each type has distinct operating characteristics and applications

Types of Pressure Relief Valves

- Pressure Relief Valve: designed to actuate on inlet static pressure and reclose after normal conditions have been restored

- Temperature and Pressure (T&P) Relief Valve: actuated by pressure at the valve inlet or by temperature at the valve inlet

- Relief Valve: characterized by gradual opening, generally proportional to the increase in pressure, used for incompressible fluids

- Safety Relief Valve: characterized by rapid opening or gradual opening, used for compressible or incompressible fluids

- Safety Valve: characterized by rapid opening, used to relieve compressible fluids

Requirements for Boilers

- Each boiler shall have at least one pressure relief valve

- Boilers with more than 500 ft2 of bare tube water-heating surface or electric boilers with a power input more than 1100 kW shall have two or more pressure relief valves

- Pressure relief valve capacity shall be such that the valve will discharge all the steam that can be generated by the boiler without allowing the pressure to rise more than 6% above the highest pressure at which any valve is set

Superheater and Reheater PRVs

- Pressure drop upstream of each pressure relief valve shall be considered in the determination of set pressure and relieving capacity of that valve

- Superheater PRV must open before the drum PRVs do and close after the drum PRVs

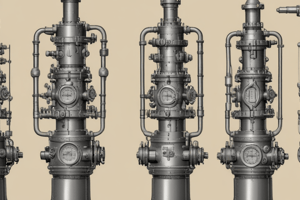

Safety Valve Construction

- Made of cast iron, steel, alloy steel, or bronze

- Used for relieving compressible fluids, commonly found on steam boilers, steam lines, compressed air vessels, and refrigerant receivers

- Consists of a spring that holds a valve disc tightly against a seat, which opens when the steam pressure reaches the set point pressure

Safety Valve Operation

- Valve disc has a lip (skirt) that forms a huddling chamber, which fills with steam when the valve starts to open, increasing the effective area of the disc

- When the valve lifts, the pressure of the steam acts on this increased disc area, resulting in a greater force against the compression spring, causing the valve to pop wide open

- The valve will remain open until the pressure drops to below the popping pressure

Blowdown

- Defined as the difference between the actual popping pressure of a pressure relief valve and the actual reseating pressure, expressed as a percentage of set pressure or in pressure units

- Minimum blowdown of 2 psi (15 kPa) or 2% of the set pressure is required by ASME BPVC I, Part PG-72.1

Installation of PRVs

- Safety valves mounted on the drum, superheater, reheater inlet and outlet headers must be placed in an upright position with the spindle vertical

- Must be connected to the boiler independent of any other steam connection, and located as close as possible to the boiler without any unnecessary intervening pipe or fitting

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.