Podcast

Questions and Answers

What is the main topic of the provided content?

What is the main topic of the provided content?

- Maintaining Hydraulic Systems

- Repairing Electronic Relays

- Repairing Pneumatic Controllers and Relays (correct)

- Types of Pneumatic Controllers

What is the purpose of a pneumatic controller?

What is the purpose of a pneumatic controller?

- To regulate the flow of air in a system (correct)

- To measure the speed of a rotating shaft

- To control the temperature of a process

- To convert electrical signals into mechanical movements

Which of these components is NOT typically found in a pneumatic controller?

Which of these components is NOT typically found in a pneumatic controller?

- Solenoid valve

- Capacitor (correct)

- Air filter

- Pressure gauge

What is the primary function of a relay in a pneumatic system?

What is the primary function of a relay in a pneumatic system?

What is the main reason why it is important to repair pneumatic controllers and relays?

What is the main reason why it is important to repair pneumatic controllers and relays?

Which of these is NOT a reason why pneumatic controllers and relays might need repair?

Which of these is NOT a reason why pneumatic controllers and relays might need repair?

What is the primary function of a pneumatic relay?

What is the primary function of a pneumatic relay?

What is the role of a pneumatic controller in a system?

What is the role of a pneumatic controller in a system?

What is a common cause of wear and tear in pneumatic controllers?

What is a common cause of wear and tear in pneumatic controllers?

What is the typical material used for the diaphragm in a pneumatic controller?

What is the typical material used for the diaphragm in a pneumatic controller?

What is the primary focus of the provided content?

What is the primary focus of the provided content?

Which of these is NOT a common reason for needing to repair a pneumatic controller?

Which of these is NOT a common reason for needing to repair a pneumatic controller?

Which of these is NOT a typical component found in a pneumatic controller?

Which of these is NOT a typical component found in a pneumatic controller?

Which of these scenarios would MOST LIKELY require the repair of a pneumatic relay?

Which of these scenarios would MOST LIKELY require the repair of a pneumatic relay?

Which of these actions is LEAST LIKELY to be involved in repairing a pneumatic controller?

Which of these actions is LEAST LIKELY to be involved in repairing a pneumatic controller?

What is a common sign that a pneumatic controller may need repair?

What is a common sign that a pneumatic controller may need repair?

Which of the following issues is likely to occur if a pneumatic relay is not functioning properly?

Which of the following issues is likely to occur if a pneumatic relay is not functioning properly?

Which of these actions would MOST LIKELY be part of a pneumatic controller repair?

Which of these actions would MOST LIKELY be part of a pneumatic controller repair?

What is a frequent cause of failure in pneumatic controllers?

What is a frequent cause of failure in pneumatic controllers?

Which component is most critical in ensuring accurate operation of a pneumatic controller?

Which component is most critical in ensuring accurate operation of a pneumatic controller?

Flashcards are hidden until you start studying

Study Notes

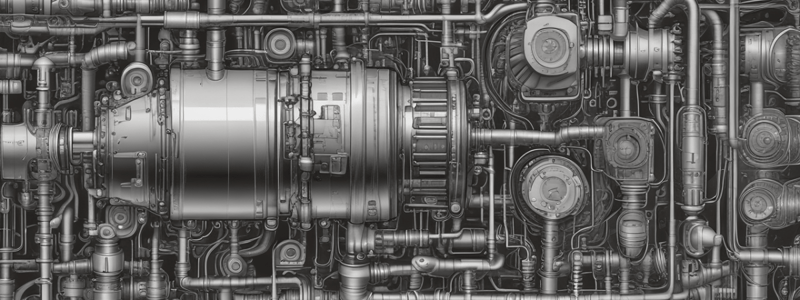

Repair of Pneumatic Controllers and Relays

- Pneumatic controllers utilize compressed air for control applications, often found in industrial automation systems.

- Regular maintenance and repair of pneumatic controllers are essential for ensuring operational efficiency and minimizing downtime.

- Common issues that require repair include air leaks, malfunctioning relays, and inaccurate pressure readings.

- Components typically needing attention include diaphragms, seals, and valves which can wear out over time.

- Troubleshooting procedures involve checking for air supply issues, inspecting connections, and testing component functionality using specialized tools.

- Replacement parts should match the original specifications to maintain system integrity and performance.

- Safety precautions are vital during repair, including depressurizing the system and using appropriate personal protective equipment (PPE).

- Following repair, proper calibration is needed to ensure the pneumatic controller functions accurately within the system.

Repair of Pneumatic Controllers and Relays

- Pneumatic controllers and relays are critical components in automation and process control systems.

- These devices rely on air pressure to regulate processes, making repairs essential for maintaining system integrity and performance.

- Common issues with pneumatic controllers include leaks, faulty actuators, and pressure regulation failures.

- Repair procedures typically involve diagnosing the failure source, replacing worn or damaged parts, and recalibrating the device.

- Regular maintenance can prevent major failures and extend the lifespan of pneumatic devices, reducing downtime.

- Understanding the circuitry and operational principles of pneumatic systems aids in effective troubleshooting and repair.

- Knowledge of industry standards and safety protocols is crucial when performing repairs to ensure compliance and worker safety.

Repair of Pneumatic Controllers and Relays

- Focus on the methods and techniques used for repairing pneumatic controllers and relays.

- Emphasis on understanding the functioning of pneumatic systems to effectively diagnose issues.

- Importance of safety protocols while handling pneumatic devices to avoid hazards during repairs.

- Knowledge of common failure points in controllers and relays, such as leaks and actuator malfunctions.

- Procedures for testing and troubleshooting malfunctioning components before repair.

- Utilization of appropriate tools and equipment for the repair of pneumatic systems.

- Understanding of the calibration process post-repair to ensure optimal system performance.

- Documentation and reporting of repair work for future reference and maintenance planning.

Repair of Pneumatic Controllers and Relays

- Pneumatic controllers manage process variables using compressed air as a control medium.

- Relays serve as control switches, enabling or disabling pneumatic systems based on input signals.

- Common issues in pneumatic systems include leaking seals, sticky valves, and faulty components, which can lead to inefficiency or failure.

- Maintenance involves regular inspection of pneumatic lines, fittings, and connections for leaks or wear.

- Repair techniques include replacing worn parts, recalibrating controllers, and ensuring proper pressure settings.

- Calibration is crucial for accurate control; it may require specialized tools and adherence to manufacturer specifications.

- Understanding the operation of components within pneumatic systems helps in diagnosing issues effectively.

- Safety precautions are vital during repair, including depressurization of systems before maintenance.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.