Podcast

Questions and Answers

An offset bend is also known as an ________.

An offset bend is also known as an ________.

offset elbow

An offset bend creates an offset, or deviation, in the pipe's ________.

An offset bend creates an offset, or deviation, in the pipe's ________.

path

A typical offset bend consists of a pipe connected to two arms or ________.

A typical offset bend consists of a pipe connected to two arms or ________.

legs

Offset bends can be manufactured from various materials, including ________, stainless ______, and PVC.

Offset bends can be manufactured from various materials, including ________, stainless ______, and PVC.

The unequal length of the arms in an offset bend creates the offset, which directs the flow at an ________ away from the centerline of the pipe.

The unequal length of the arms in an offset bend creates the offset, which directs the flow at an ________ away from the centerline of the pipe.

Offset bends offer several advantages over traditional elbows, particularly in certain ________.

Offset bends offer several advantages over traditional elbows, particularly in certain ________.

The offset angle enables designers to direct the flow away from ______ components or areas

The offset angle enables designers to direct the flow away from ______ components or areas

Offset bends are easier to install than traditional elbows, as they do not require additional straight sections to be added to the pipe ______

Offset bends are easier to install than traditional elbows, as they do not require additional straight sections to be added to the pipe ______

Offset bends are commonly used in chemical processing plants to direct the flow of fluids around ______ equipment

Offset bends are commonly used in chemical processing plants to direct the flow of fluids around ______ equipment

In oil and gas refineries, offset bends are used to direct the flow of fluids around equipment and minimize ______ loss

In oil and gas refineries, offset bends are used to direct the flow of fluids around equipment and minimize ______ loss

Water treatment plants use offset bends to control the flow of water around ______ equipment

Water treatment plants use offset bends to control the flow of water around ______ equipment

Choose materials that are compatible with the fluids being transported and the operating conditions of the system when considering offset bend ______

Choose materials that are compatible with the fluids being transported and the operating conditions of the system when considering offset bend ______

Flashcards are hidden until you start studying

Study Notes

Offset Bends in Pipe Fitting Applications

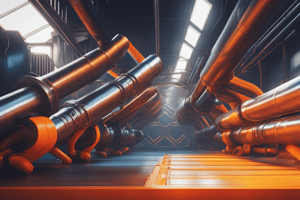

In piping systems, an offset bend, also known as an offset elbow, is a specific type of pipe fitting that helps direct the flow of liquids and gases along a desired path while maintaining integrity and efficiency. This article will delve into the definition, advantages, and applications of offset bends.

Definition

An offset bend, as the name suggests, is a type of elbow fitting that creates an offset, or deviation, in the pipe's path. A typical offset bend consists of a pipe connected to two arms or legs, with one arm shorter than the other. This unequal length creates the offset, which directs the flow at an angle away from the centerline of the pipe. Offset bends can be manufactured from various materials, including steel, stainless steel, and PVC, and they come in a wide range of sizes and configurations to suit different applications.

Advantages

Offset bends offer several advantages over traditional elbows, particularly in certain applications. These advantages include:

-

Space savings: Offset bends are more compact than standard elbows, as they don't require additional space for straight sections between the bend and the pipe. This space-saving property is particularly useful in applications where space is at a premium, such as within confined areas or vessels with limited internal space.

-

Flow control: Offset bends provide precise control over the flow of fluids. The offset angle enables designers to direct the flow away from sensitive components or areas, preventing unwanted fluid accumulation or spillage. This control also helps to minimize pressure loss and maintain optimal flow efficiency.

-

Ease of installation: Offset bends are easier to install than traditional elbows, as they do not require additional straight sections to be added to the pipe run. This factor, combined with their space-saving properties, results in a more streamlined installation process.

Applications

Offset bends have a wide range of applications across various industries, including:

-

Chemical processing: Offset bends are commonly used in chemical processing plants to direct the flow of fluids around sensitive equipment and control flow rates. Vortex shedding, a phenomenon that occurs when a fluid flows through an offset bend, can also be harnessed to create self-cleaning filters and separators.

-

Oil and gas: Offset bends are used in oil and gas refineries to direct the flow of fluids around equipment and minimize pressure loss. They are also used in drilling and production facilities to control the flow of fluids and prevent fluid accumulation in critical areas.

-

Water treatment: Offset bends are used in water treatment plants to control the flow of water around filtration equipment and minimize the risk of sediment build-up. They are also used in wastewater treatment facilities to manage the flow of wastewater and prevent the formation of unwanted deposits.

-

HVAC and plumbing: Offset bends are used in HVAC and plumbing applications to control the flow of fluids and reduce noise. They are also used in fire protection systems to direct the flow of water around critical equipment and minimize pressure loss.

Considerations

When designing and installing offset bends, it is essential to consider the following factors:

-

Materials selection: Choose materials that are compatible with the fluids being transported and the operating conditions of the system.

-

Sizing: Ensure that the offset bend is appropriately sized for the flow rate, pressure, and temperature conditions of the system.

-

Installation: Install offset bends correctly to ensure that they perform as intended and to minimize the risk of leakage or damage.

-

Maintenance: Regularly inspect and maintain offset bends to ensure that they continue to perform as intended and to prevent premature failure.

In summary, offset bends are an essential component in piping systems, offering advantages such as space savings, flow control, and ease of installation. They are used across various industries, including chemical processing, oil and gas, water treatment, HVAC, and plumbing. When designing and installing offset bends, it is essential to consider factors such as materials selection, sizing, installation, and maintenance. By following best practices, you can ensure that offset bends help to optimize the performance of piping systems while minimizing the risk of failure.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.